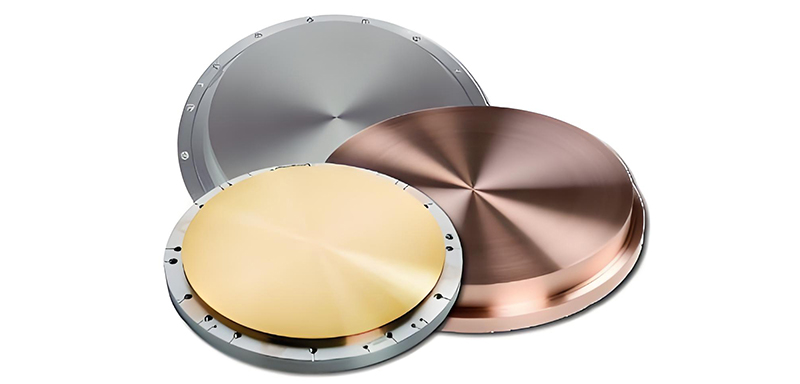

Alloy Sputtering Targets

Alloy sputtering targets are materials used in thin-film deposition processes, where high-energy ions bombard the target to release atoms that are then deposited onto a substrate. Alloys, composed of two or more metals, are often selected for sputtering due to their superior physical properties, such as enhanced conductivity, durability, and resistance to wear and corrosion. They are essential in producing films with specific qualities that are crucial for industries such as semiconductor fabrication, optoelectronics, aerospace, and solar energy. By combining multiple metals, alloy sputtering targets can be designed to meet unique application needs, providing tailored solutions that single-element targets cannot.

The versatility of alloy sputtering targets is one of their greatest strengths. Whether used for magnetic, optical, or electrical coatings, these targets allow for precise control over material composition, ensuring that the final thin films have the desired characteristics. Alloy sputtering is a key process in the production of many advanced technological components, making alloy targets indispensable in cutting-edge manufacturing processes.

Types of Alloy Sputtering Targets

Key Alloy Materials and Compositions

Benefits of Using Alloy Sputtering Targets

Alloy sputtering targets offer several distinct advantages over pure metal targets. The primary benefit is the ability to tailor the physical and chemical properties of the sputtered thin films by adjusting the composition of the alloy. This customization allows for enhanced performance in various applications, such as improved conductivity, wear resistance, or corrosion resistance.

In addition, alloy targets can offer better material utilization, as the sputtering process typically results in a more uniform deposition of material. Alloy sputtering targets also provide superior film durability, with films that maintain their properties under extreme environmental conditions. This makes alloy targets particularly suitable for industries that require long-lasting, high-performance coatings.

Custom Alloy Sputtering Targets

We specialize in providing custom alloy sputtering targets to meet the specific requirements of our customers. By working closely with clients, we can develop alloy compositions that are optimized for unique applications, whether it’s for high-temperature environments, specific electrical properties, or enhanced durability. Our custom alloy targets are manufactured to the highest standards of purity and consistency, ensuring precise and reliable thin-film deposition.

Whether you need a unique alloy combination for your solar cell manufacturing or specialized alloys for aerospace applications, we offer flexible solutions to meet your needs. Our team is ready to assist with the design, production, and delivery of custom alloy sputtering targets, ensuring that you have the ideal materials for your project.

Why Choose Us for Alloy Sputtering Targets?

Our alloy sputtering targets are made with the highest quality materials and precision manufacturing processes. We are committed to providing our customers with superior sputtering targets that deliver consistent performance and meet the most stringent industry standards. Our extensive range of alloys, combined with our ability to offer custom formulations, ensures that we can meet the unique needs of any application.

We pride ourselves on delivering exceptional customer service, with fast turnaround times, global shipping options, and comprehensive technical support. Whether you’re in semiconductor manufacturing, aerospace, medical devices, or any other industry, we have the expertise and experience to supply the alloy sputtering targets you need for your applications.