Customizable Materials for Thin-Film Deposition: Meeting Industry-Specific Needs

Thin-film deposition is a cornerstone of modern technology, powering advancements in semiconductors, optics, energy, and aerospace. The demand for precision and performance has pushed materials science to develop sputtering targets, evaporation materials, and other thin-film resources tailored to exact application needs. Customization, guided by technical parameters and innovative approaches, has become vital for achieving optimal results across diverse industries.

The Science Behind Thin-Film Materials

Thin-film deposition involves creating layers with thicknesses ranging from a few nanometers to micrometers. The material properties of the films depend heavily on the input materials’ composition, purity, and structure. Technical specifications critical for customized materials include:

Technical Customization by Industry

Data-Driven Customization

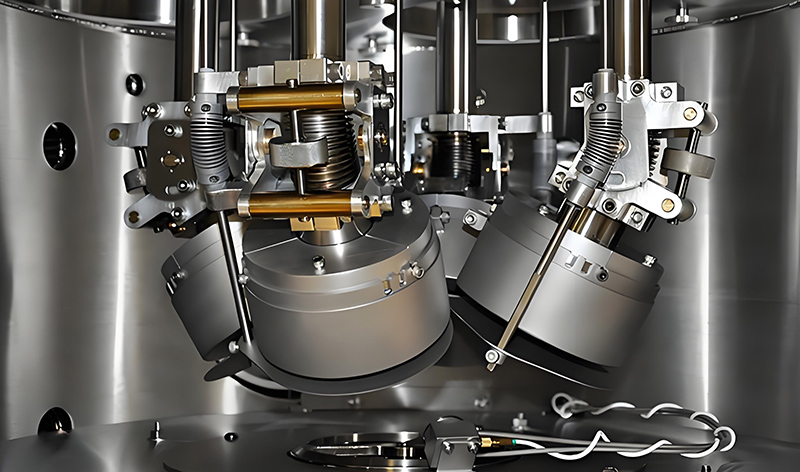

At Tinsan Materials, we rely on industry data and advanced material characterization to deliver solutions that meet technical demands. For instance:

Why Tinsan Materials?

Our expertise lies in providing tailored sputtering targets, evaporation materials, and other thin-film resources, with:

Customizable thin-film deposition materials are driving technological breakthroughs across industries. By leveraging advanced science, technical expertise, and a commitment to quality, Tinsan Materials delivers solutions that exceed performance expectations, ensuring a competitive edge for our clients.

References: Technical specifications and material properties are derived from industry research and publications in thin-film materials science.