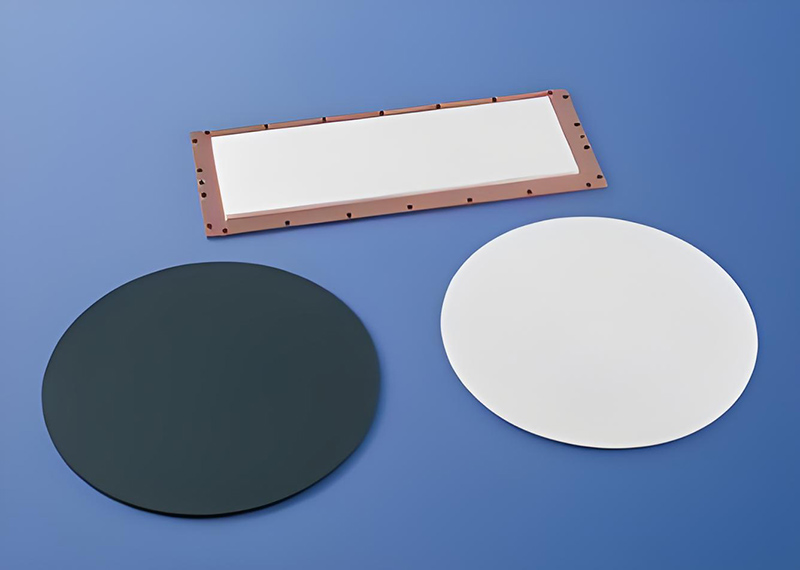

Ceramic Sputtering Targets

Ceramic sputtering targets are advanced materials used in the process of thin-film deposition, which is essential for a wide variety of applications across different industries. Unlike metallic sputtering targets, ceramic targets are typically chosen for their exceptional properties such as high thermal stability, electrical insulation, and chemical resistance. The sputtering process involves bombarding a ceramic target with ions to release atoms, which then deposit onto a substrate to form thin films. These films are used in electronics, optics, coatings, and other technologies where precise and durable thin films are needed. Ceramic sputtering targets are ideal for applications requiring films with high hardness, wear resistance, and corrosion resistance.

Types of Ceramic Sputtering Targets

Ceramic sputtering targets are classified based on their composition, and each type serves specific purposes:

Materials Used for Ceramic Sputtering Targets

Ceramic sputtering targets can be made from a variety of materials, each offering distinct advantages based on the intended application:

These materials are selected based on their specific characteristics such as thermal conductivity, hardness, and corrosion resistance, which are tailored to meet the needs of different industrial applications.

Benefits of Using Ceramic Sputtering Targets

Ceramic sputtering targets provide several key advantages over traditional metal sputtering targets, making them ideal for a wide range of applications:

Advantages of Choosing Our Ceramic Sputtering Targets

Choosing our ceramic sputtering targets ensures that you receive products of the highest quality, designed to meet the most demanding industry standards. Our targets are engineered for superior performance and consistency, helping you achieve precise thin-film deposition for your applications. With expert technical support, we offer tailored solutions to optimize your production processes and reduce operational costs. Additionally, we pride ourselves on our global supply chain, offering fast delivery times and competitive pricing for both standard and custom ceramic targets. Our commitment to quality and customer satisfaction makes us a reliable partner for all your ceramic sputtering needs.

Custom Ceramic Sputtering Targets

We offer custom ceramic sputtering targets designed to meet the specific requirements of our clients. Our team works closely with customers to tailor the target material composition, size, and thickness to suit their application needs. Custom targets allow for precise control over the properties of the deposited thin films, ensuring optimal performance for specialized applications. Whether it’s for high-performance coatings in the automotive industry or specialized dielectric films in the semiconductor sector, our custom targets provide the exact material properties needed to enhance your product’s functionality and durability.

Why Ceramic Sputtering Targets Are a Superior Choice

Ceramic sputtering targets offer distinct advantages over traditional metal sputtering targets in several key areas. While metals are often used in sputtering, ceramic materials are generally more durable, offering better resistance to high temperatures, oxidation, and corrosion. This makes them the preferred choice for industries such as aerospace, semiconductors, and optics, where the longevity and reliability of thin films are critical. Additionally, ceramics can be customized to provide unique optical, electrical, and mechanical properties, ensuring that they can be tailored for specific applications. For industries that require coatings with high precision, durability, and performance under harsh conditions, ceramic sputtering targets offer a superior solution.

Ceramic sputtering targets provide an excellent solution for industries requiring high-performance thin films with superior durability and stability. Their versatility in composition allows for customization to meet a wide variety of application needs, from semiconductors and optoelectronics to aerospace and automotive industries. The benefits of ceramic materials, such as high thermal stability, wear resistance, and electrical insulation, make them an ideal choice for demanding coating applications. If you’re looking for reliable, high-quality sputtering targets, our ceramic sputtering targets provide the precision and durability you need to achieve optimal results in your thin-film deposition processes. Contact us today for custom solutions or to discuss your specific requirements.