Evaporation Materials

Evaporation materials are essential components in thin-film deposition, enabling the creation of high-quality coatings for a wide range of industries. From semiconductors to optical devices, these materials play a critical role in ensuring reliable and efficient performance. At Tinsan Materials, we specialize in providing premium evaporation materials tailored to meet the needs of various applications, including electronics, optics, energy, and medical devices.

What Are Evaporation Materials?

Evaporation materials are substances used in physical vapor deposition (PVD) techniques, such as thermal evaporation and electron-beam evaporation. In these processes, the materials are heated in a vacuum chamber until they vaporize, forming a thin, uniform coating on the substrate.

Evaporation Processes

1. Thermal Evaporation:

2. Electron-Beam Evaporation:

Compared to other deposition methods, such as sputtering, evaporation offers advantages like faster deposition rates, lower substrate heating, and better film quality.

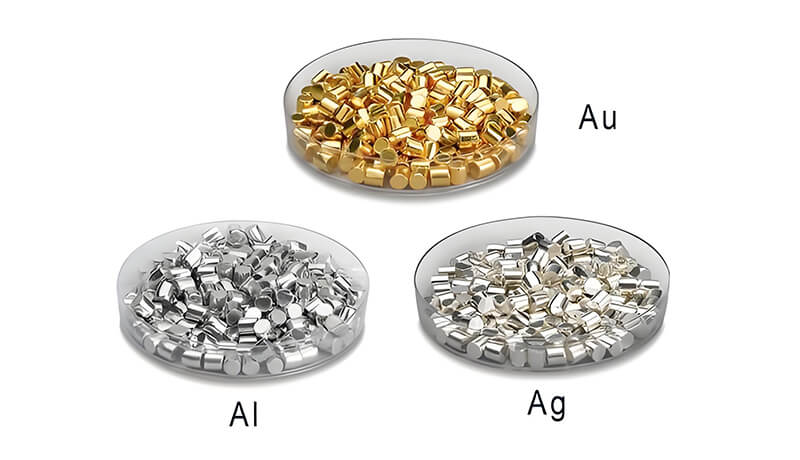

Types of Evaporation Materials

We offer a wide range of evaporation materials to suit diverse industry needs:

1. Metals

2. Alloys

3. Ceramics

4. Composites

5. Organic Materials

Key Properties of Evaporation Materials

To ensure optimal performance, evaporation materials must meet stringent quality standards:

1. High Purity:

2. Thermal Stability:

3. Melting Point:

4. Chemical Compatibility:

5. Uniform Particle Size:

Production and Quality Control

We utilize advanced production techniques and rigorous quality control measures to deliver top-quality evaporation materials.

1. Manufacturing Processes

2. Quality Assurance

Customization Options

We understand that every application is unique. We provide comprehensive customization services to meet specific requirements:

We collaborate closely with clients to design evaporation materials that optimize deposition processes and ensure cost-effectiveness.

Explore our full range of evaporation materials and discover how Tinsan Materials can support your thin-film deposition needs. Please contact us to learn more or request a quote!