Showing 49–60 of 334 results

-

- High Purity: Available with ≥99.9% purity for optimal performance.

- Topological Insulator Properties: Enables applications in quantum computing and advanced electronics.

- Excellent Thermoelectric Efficiency: Ideal for energy harvesting and cooling systems.

- Customizable Particle Sizes: Nano and micro scales tailored to specific applications.

- Stable Composition: Chemically stable and resistant to degradation.

- Environmentally Friendly: Non-toxic and suitable for sustainable technologies.

-

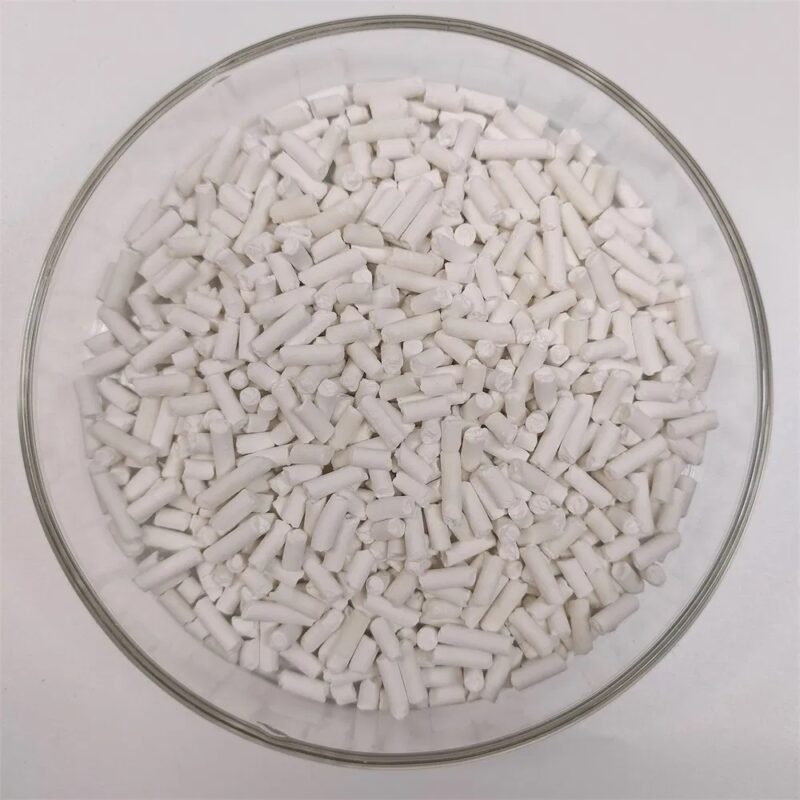

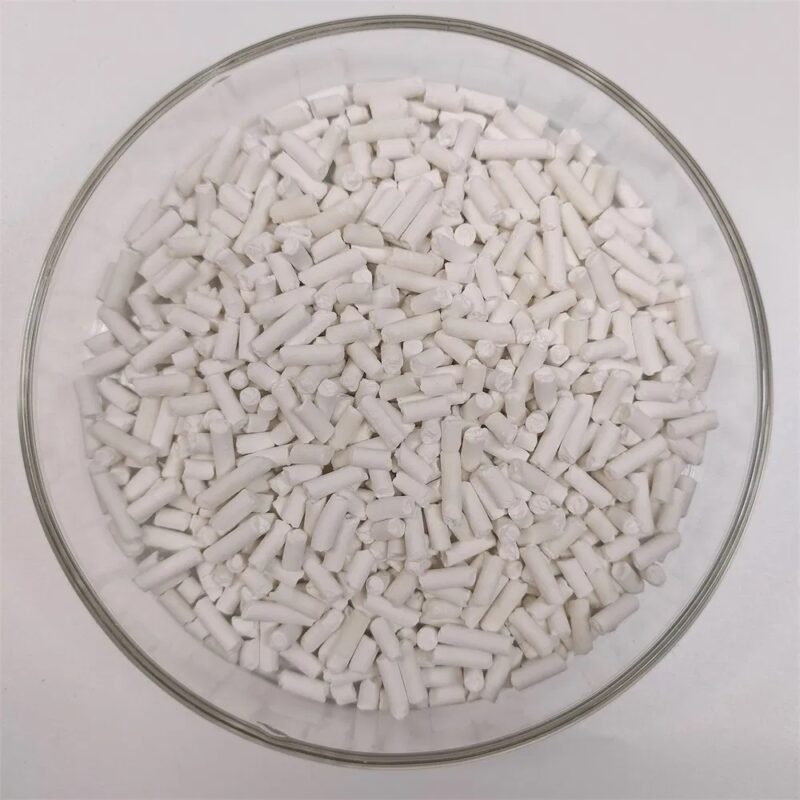

- High purity (≥99.99%).

- Exceptional thermoelectric properties.

- High electrical and thermal conductivity.

- Uniform pellet size for consistent deposition and performance.

- Customizable sizes and packaging for various applications.

-

- High Purity: Available with ≥99.9% purity for optimal material properties.

- Outstanding Thermoelectric Performance: High Seebeck coefficient and low thermal conductivity.

- Layered Crystal Structure: Enables superior electrical and thermal characteristics.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) sizes tailored to specific requirements.

- Stable and Durable: Chemically stable and resistant to environmental degradation.

- Environmentally Friendly: Non-toxic and suitable for sustainable applications.

-

- Low Melting Point: Excellent for low-temperature soldering and thermal interface materials.

- Thermoelectric Properties: Exhibits promising performance in energy harvesting systems.

- Customizable Particle Size: Available in various sizes tailored to application needs.

- High Purity: Ensures reliable performance in precision applications.

- Environmentally Friendly: Contains no lead, making it suitable for eco-friendly applications.

-

- High Purity: BiSb pellets are typically available in high purity (99.9% or higher), ensuring the production of high-quality thin films free from contaminants.

- Thermoelectric Efficiency: The combination of Bismuth and Antimony provides exceptional thermoelectric properties, which is crucial for enhancing energy conversion efficiency in thin films.

- Uniform Evaporation: The spherical or irregular shape of the pellets allows for even melting and vaporization during the evaporation process, resulting in uniform deposition on substrates.

- Low Melting Point: BiSb alloys have a relatively low melting point, making them easier to handle in evaporation systems without the need for extreme temperatures.

-

- High Thermal Conductivity: Excellent ability to dissipate heat, ideal for high-temperature applications.

- Electrical Insulation: Acts as an efficient insulator while maintaining high thermal conductivity.

- Chemical Stability: Resistant to chemical corrosion, oxidation, and high-temperature degradation.

- Lubrication Properties: Provides natural lubrication in extreme environments, reducing friction and wear.

- Customizable Particle Size: Available in various sizes, tailored for specific applications.

-

- High Thermal Conductivity: Excellent heat dissipation properties.

- Electrical Insulation: Exceptional dielectric strength, ideal for electronic applications.

- Chemical Inertness: Resistant to oxidation and most chemicals.

- High Purity: Available with ≥99% purity for consistent and reliable performance.

- Lubricating Properties: Superior lubricity, even at high temperatures.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) options available or customized.

-

- High Hardness: Carbon, especially in its diamond-like form, is extremely hard and wear-resistant, making it suitable for protective coatings.

- High Melting Point: Sublimation point of carbon is around 3,650°C, allowing its use in high-temperature deposition processes.

- Good Electrical Conductivity: Carbon is conductive, making it suitable for electronic applications.

- Chemically Inert: Carbon’s chemical stability ensures it remains durable in corrosive environments, enhancing the lifespan of coated materials.

- Low Coefficient of Friction: Diamond-like carbon (DLC) films offer excellent lubricity and are used to reduce wear in mechanical systems.

-

- High Electrical Conductivity: Especially in the form of graphite, carbon powder is widely used in applications requiring good electrical conduction.

- Thermal Stability: Carbon is highly resistant to heat and can withstand extreme temperatures, making it ideal for refractory and high-temperature applications.

- Lubrication: Graphite powder acts as a dry lubricant, reducing wear and friction between moving parts under high temperature conditions.

- Chemical Inertness: Carbon is resistant to many chemicals, which makes it suitable for use in harsh environments where it will not react or degrade easily.

- Adsorption: Activated carbon has exceptional adsorption capabilities, making it effective in filtration and environmental clean-up applications.

- Reinforcement: Carbon black provides strength and durability when added to materials such as rubber and plastics.

-

- Exceptional Corrosion Resistance: Resistant to pitting, crevice corrosion, and stress corrosion cracking in aggressive environments.

- High Strength: Maintains mechanical integrity under high stress and temperature conditions.

- Weldability: Excellent compatibility with various welding methods, including TIG, MIG, and laser welding.

- Versatility: Suitable for additive manufacturing, powder metallurgy, and thermal spray coating applications.

- Thermal Stability: Performs reliably across a wide range of temperatures without compromising material properties.

-

- High Reactivity: Calcium easily reacts with oxygen and nitrogen, making it ideal for certain oxidation-controlled processes.

- High Purity: Available in high-purity forms (≥ 99.9%), ensuring minimal impurities in thin film coatings.

- Good Evaporation Characteristics: Calcium has a relatively low evaporation temperature (842°C), allowing efficient deposition in vacuum environments.

- Versatile Applications: Calcium can be used for coatings that require lightweight, high-performance films in various high-tech applications.

-

- Broad Transparency Range: CaF₂ has excellent transmission from the UV (below 200 nm) to the IR (~10 µm) range, which makes it ideal for a wide variety of optical applications.

- Low Refractive Index: The material has a relatively low refractive index (~1.43), which minimizes Fresnel reflection losses and is useful in anti-reflective coatings.

- High Thermal Stability: CaF₂ can withstand high temperatures during evaporation, ensuring the stability of the material during thin-film deposition processes.

- Chemical Resistance: Calcium fluoride is chemically inert, offering durability and resistance to environmental degradation.

- Low Absorption: Its low absorption makes it suitable for high-power laser applications, especially in the UV region.