Showing 1–12 of 21 results

-

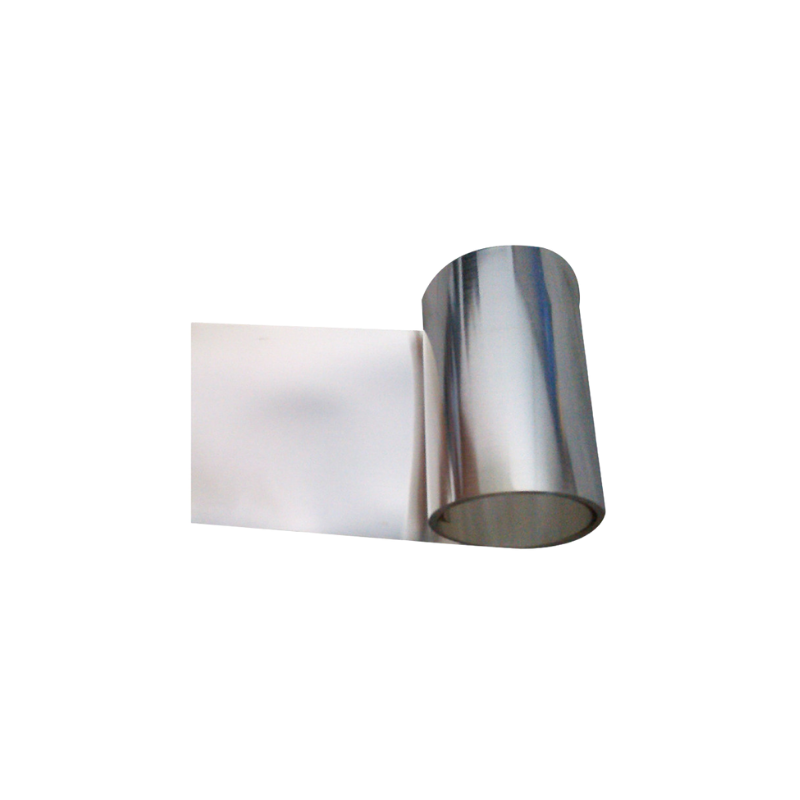

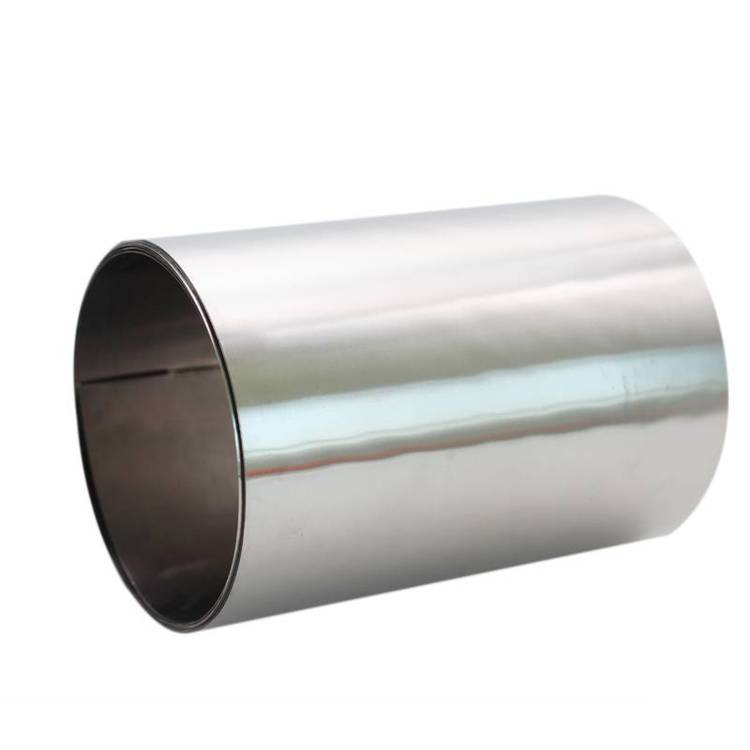

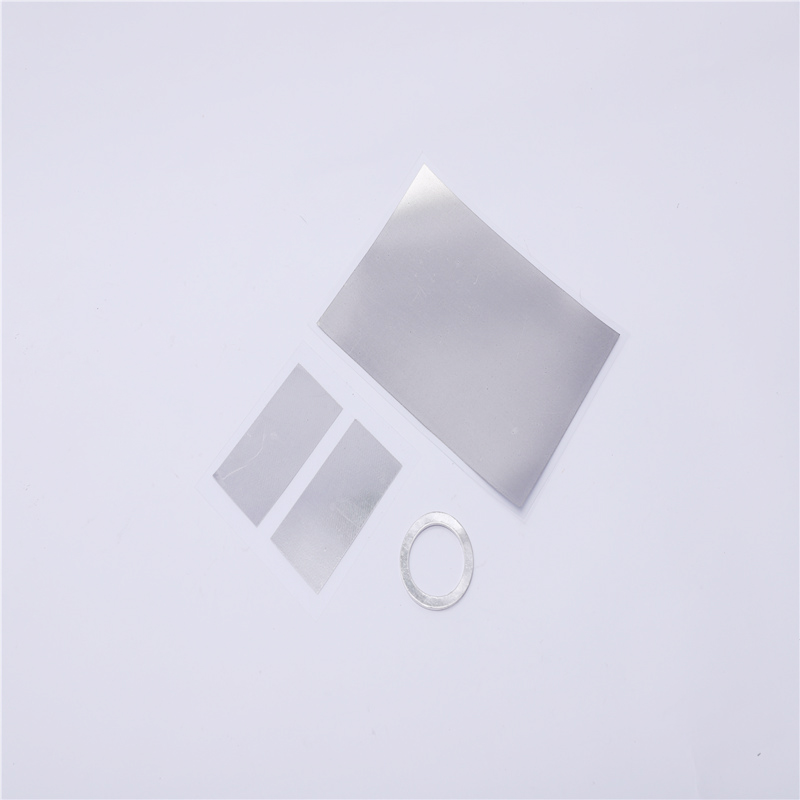

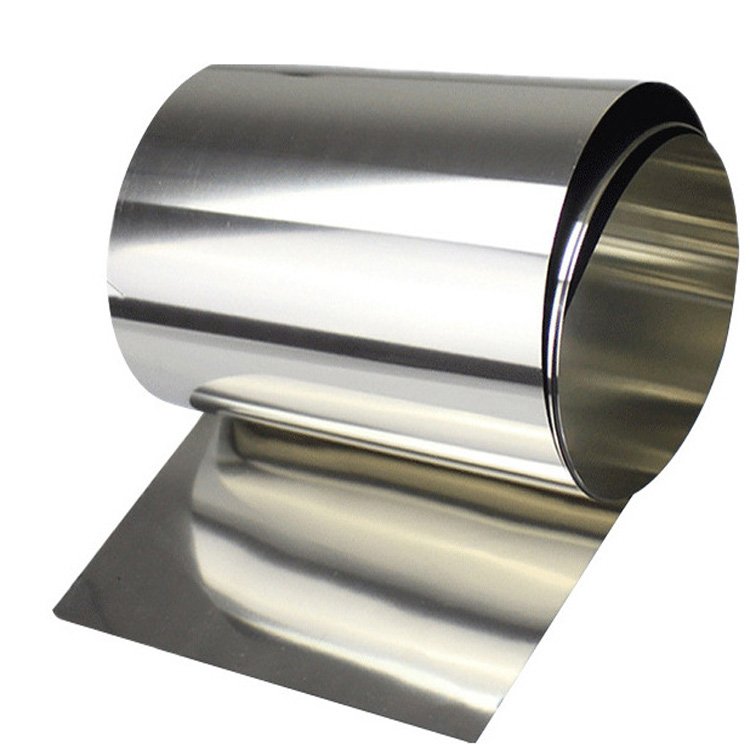

- High Electrical Conductivity: Silver foil is renowned for its superior electrical conductivity, making it essential for electronic components such as circuits and connectors.

- Excellent Thermal Conductivity: Silver has excellent thermal conductivity, allowing it to efficiently transfer heat, making it useful in applications that require heat dissipation.

- Corrosion Resistance: Silver foil is resistant to oxidation and corrosion, which ensures its longevity even in harsh environments.

- Malleability and Ductility: Silver foil is highly malleable, which allows it to be easily shaped into thin sheets or forms without breaking. This malleability adds to its versatility in various applications.

- Reflective Surface: Silver foil has a high reflective surface, which makes it ideal for use in optics and reflective coatings.

- Non-Toxic and Safe: Silver foil is non-toxic and safe for use in a wide range of applications, including food packaging and medical devices.

-

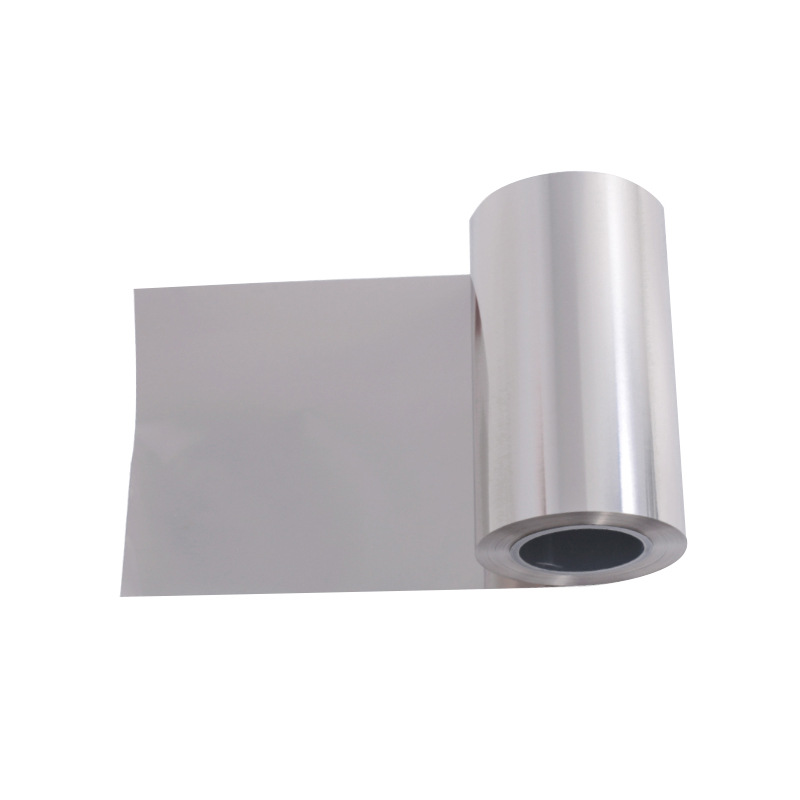

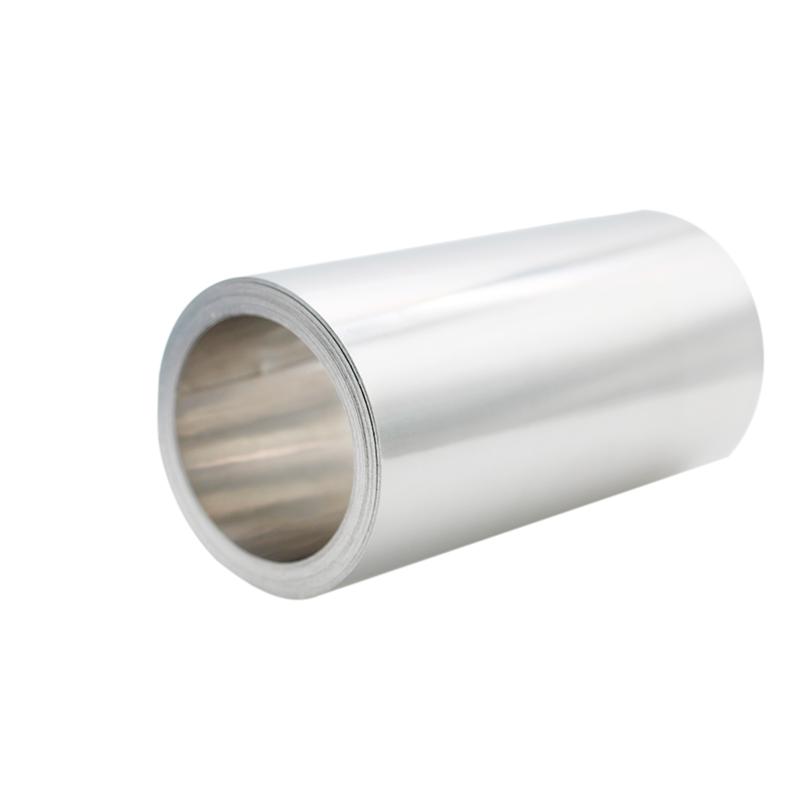

- Lightweight: Aluminium foil has a low density, making it an ideal choice for weight-sensitive applications.

- High Thermal and Electrical Conductivity: Excellent heat and electricity conduction properties make it suitable for insulation and electronic components.

- Corrosion Resistance: Aluminium foil forms a natural oxide layer that provides strong protection against corrosion.

- Ductility: Aluminium foil is highly malleable, allowing it to be formed into various shapes and sizes.

- Reflectivity: Its reflective surface helps in heat insulation and decorative applications.

-

- High Purity: Gold foil is typically made from high-purity gold, often 99.99% pure or greater. The high purity ensures excellent performance in sensitive applications such as electronics and medical devices.

- Malleability and Ductility: Gold is one of the most malleable and ductile metals, which means it can be easily shaped or stretched without breaking. This property makes gold foil ideal for precise applications where flexibility and thinness are required.

- Excellent Electrical Conductivity: Gold foil has superior electrical conductivity, making it ideal for use in high-performance electronic devices such as connectors, semiconductors, and microelectronics.

- Corrosion and Oxidation Resistance: Gold’s natural resistance to corrosion and oxidation makes gold foil an excellent choice for applications exposed to harsh environments. It does not tarnish, rust, or corrode, ensuring long-term durability and reliability.

- Thermal Conductivity: Gold foil offers high thermal conductivity, which is useful in heat dissipation applications in electronic devices and aerospace technology, where managing heat is critical.

- Biocompatibility: Gold is biocompatible, meaning it is safe for use in medical and dental applications. It does not cause adverse reactions in the body, making it ideal for implants and other medical devices.

- Reflectivity: Gold foil has excellent optical reflectivity, especially in infrared wavelengths, making it valuable in specialized coatings and mirrors for scientific instruments, telescopes, and other optical applications.

-

- Magnetic Properties: Cobalt is ferromagnetic, meaning it can retain magnetization, making cobalt foil ideal for applications requiring strong and stable magnetic fields. It is often used in magnetic recording media, electric motors, and magnetic shields.

- Corrosion Resistance: Cobalt foil offers excellent resistance to corrosion, especially in harsh environments such as high humidity, acidic conditions, and exposure to alkalis. This makes it a suitable material for use in chemical processing and marine environments.

- High Strength and Durability: Cobalt has a high tensile strength and is resistant to wear and tear. The durability of cobalt foil makes it a reliable choice for high-stress applications, including components exposed to high mechanical loads.

- High Melting Point: Cobalt has a relatively high melting point of 1,495°C (2,723°F), making cobalt foil suitable for high-temperature environments such as those found in aerospace, electronics, and industrial applications.

- Thermal Stability: Cobalt foil exhibits excellent thermal stability, retaining its strength and performance under a wide range of temperature conditions. It is often used in applications where materials are exposed to high temperatures and fluctuating thermal environments.

- Biocompatibility: Cobalt is biocompatible, making cobalt foil suitable for use in certain medical and dental applications. It is used in implants, prosthetics, and other devices where contact with the human body is required.

-

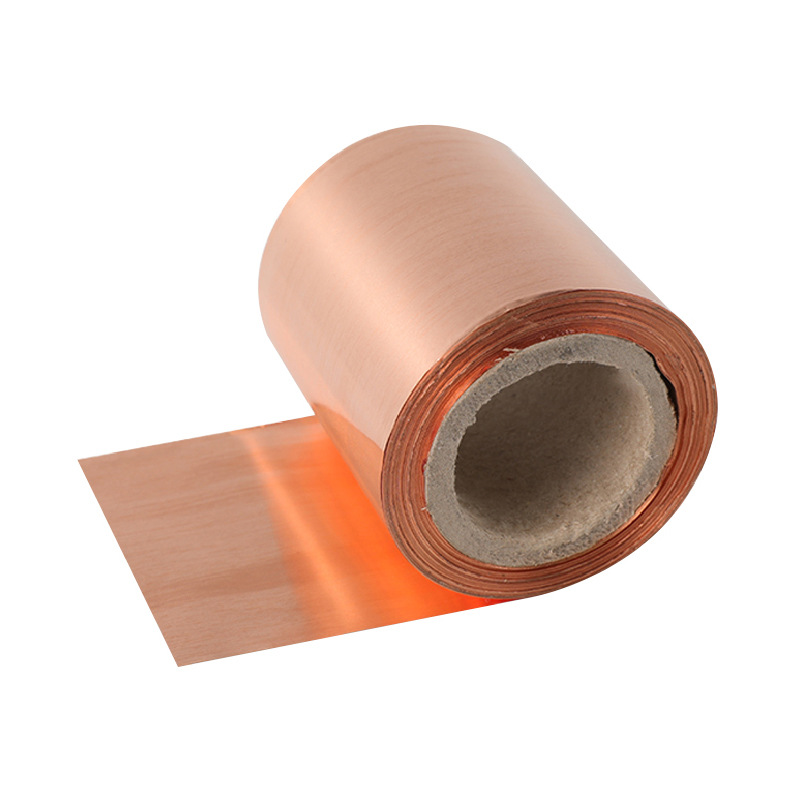

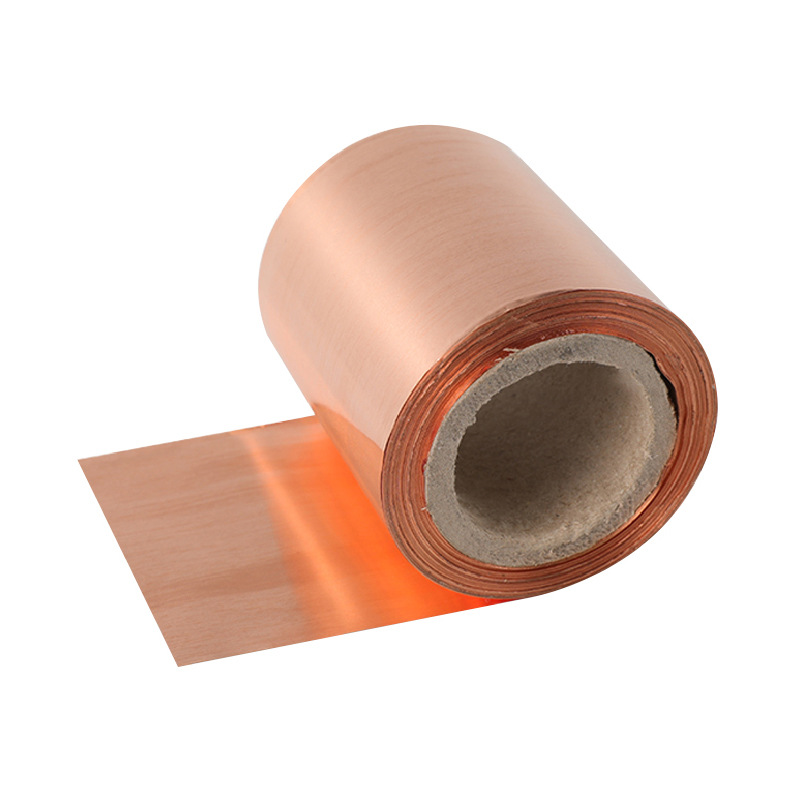

- High Electrical Conductivity: Copper foil is known for its excellent electrical conductivity, making it ideal for use in electrical and electronic applications. It allows the efficient flow of electrical current with minimal resistance, which is crucial in devices like circuit boards, power systems, and transformers.

- Thermal Conductivity: Copper is one of the best materials for heat conduction. Copper foil efficiently dissipates heat, making it essential in applications such as heat sinks, thermal management, and cooling systems.

- Corrosion Resistance: Copper foil naturally forms a protective oxide layer on its surface, which helps resist corrosion, especially in environments exposed to moisture or chemicals. This makes copper foil durable and suitable for a range of industrial applications.

- Malleability and Ductility: Copper foil is highly malleable and can be easily formed into various shapes and sizes without cracking. This flexibility allows for diverse uses in manufacturing, especially for flexible printed circuits and various packaging applications.

- Lightweight: Copper foil is lightweight, making it easy to handle and transport. Despite its lightness, it maintains excellent mechanical strength and durability, making it an attractive option for many industries that require both strength and weight reduction.

- Recyclability: Copper is 100% recyclable without losing its properties. This makes copper foil an environmentally friendly choice, as it can be reused multiple times, reducing waste and supporting sustainable practices.

-

- Magnetic Properties: Iron foil possesses strong magnetic properties, making it essential for use in applications involving electromagnetism, such as transformers and electric motors.

- Strength and Durability: Iron foil is known for its strength and ability to withstand mechanical stresses, ensuring durability in industrial applications.

- Malleability and Flexibility: Iron foil is highly malleable and flexible, allowing it to be easily shaped into thin sheets, making it adaptable for various applications.

- Corrosion Resistance: While iron is generally prone to oxidation, specially treated iron foil can exhibit excellent resistance to corrosion and rust, increasing its longevity.

- Thermal Conductivity: Iron foil has moderate thermal conductivity, making it suitable for applications that require heat distribution.

- Low Cost: Iron foil is cost-effective compared to other metallic foils like gold or silver, making it an affordable solution for various applications.

-

- High Melting Point: Hafnium has a very high melting point of 2,233°C (4,051°F), which makes it ideal for applications in extreme heat environments. This property is crucial for components exposed to high temperatures, such as in aerospace and nuclear reactors.

- Excellent Corrosion Resistance: Hafnium foil is highly resistant to corrosion, even in the presence of strong acids or high-temperature environments. This makes it an ideal material for use in chemically aggressive settings, ensuring long-term reliability and durability.

- Good Electrical Conductivity: While hafnium is not as conductive as copper, it still offers good electrical conductivity for many specialized applications. This makes hafnium foil useful in electronic components and semiconductors.

- High Neutron Absorption Capacity: Hafnium has an exceptional ability to absorb neutrons, making it ideal for nuclear applications such as control rods in nuclear reactors. The high neutron absorption properties make it an essential material in radiation shielding and nuclear power generation.

- Low Thermal Expansion: Hafnium foil exhibits low thermal expansion, meaning it does not easily deform under temperature changes. This property is valuable in applications that require dimensional stability when subjected to fluctuating temperatures.

- Biocompatibility: Hafnium is biocompatible, which means it can be used in medical applications without causing adverse reactions. This is particularly important in certain types of surgical and implantable devices.

-

- High Ductility and Malleability: Indium foil is exceptionally soft and pliable, allowing it to conform to complex shapes without cracking or losing its integrity.

- Thermal Conductivity: Indium foil efficiently transfers heat, making it an excellent thermal interface material (TIM) in electronics and other high-precision applications.

- Electrical Conductivity: With its excellent electrical conductivity, indium foil is often used in electrical and electronic devices.

- Corrosion Resistance: Indium has good resistance to corrosion and oxidation, making it reliable for long-term use in harsh environments.

- Low Melting Point: Indium has a relatively low melting point of 156.6°C, which allows it to be used in specialized low-temperature soldering applications.

- Non-Toxic and Biocompatible: Indium foil is non-toxic and safe for use in medical and scientific applications.

-

- High Melting Point: With a melting point of 2623°C, molybdenum foil can withstand extreme temperatures.

- Thermal and Electrical Conductivity: Molybdenum exhibits excellent thermal and electrical conductivity, essential for heat dissipation and electrical components.

- High Purity: Available in ultra-high purity grades, ensuring consistent performance in sensitive applications.

- Corrosion Resistance: Molybdenum is highly resistant to oxidation and corrosion, even in extreme environments.

- Strength and Stability: Molybdenum foil maintains mechanical strength and dimensional stability at high temperatures.

- Malleability and Workability: Despite its robustness, molybdenum foil is malleable and can be fabricated into complex shapes.

-

- High Corrosion Resistance: Niobium foil offers exceptional resistance to corrosion, particularly in acidic environments. It forms a stable oxide layer on its surface, protecting it from further corrosion in harsh chemicals and high-temperature conditions.

- High Melting Point: Niobium has a high melting point of around 2,468°C (4,474°F), making it suitable for high-temperature applications, such as those in the aerospace and automotive industries.

- Excellent Ductility and Malleability: Niobium foil is highly ductile and malleable, allowing it to be easily formed into thin, flexible sheets without compromising its mechanical properties. This makes it ideal for custom fabrication in precision applications.

- Low Thermal Expansion: Niobium has a relatively low coefficient of thermal expansion, which ensures that it maintains stability and does not deform easily under thermal stress. This property is beneficial in applications requiring high thermal stability.

- Biocompatibility: Niobium is biocompatible and is often used in medical implants and devices, such as pacemakers and stents, without causing adverse reactions in the human body.

- Superconductivity: Niobium exhibits superconducting properties at low temperatures, making it useful in various scientific and medical applications, such as MRI machines and particle accelerators.

-

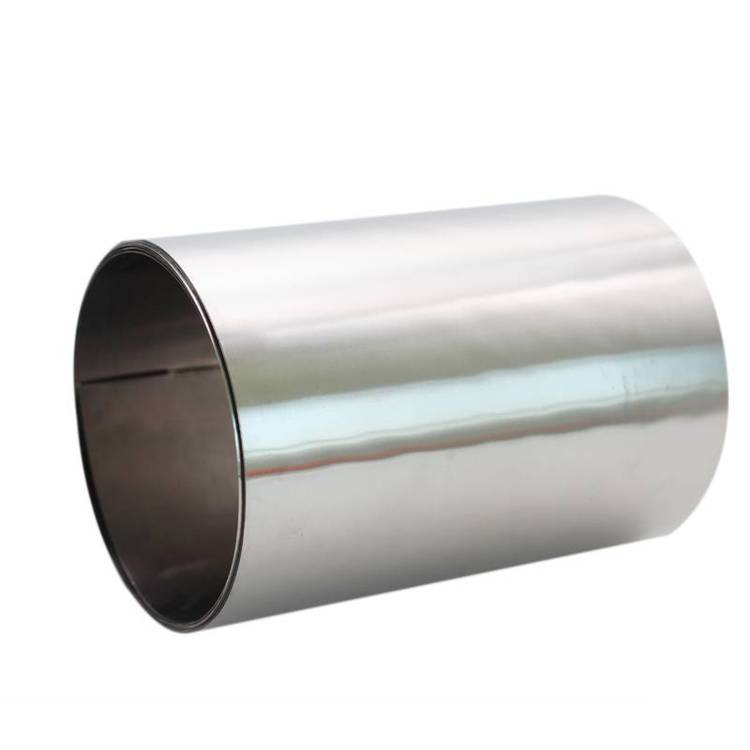

- Corrosion Resistance: Nickel foil is highly resistant to corrosion, especially in harsh environments, making it suitable for applications in corrosive conditions like chemical processing and marine industries.

- High Thermal Stability: Nickel foil maintains its performance at high temperatures, ensuring stable functionality in high-heat applications such as furnaces and heat exchangers.

- Excellent Electrical Conductivity: Known for its good electrical conductivity, nickel foil is used in the electronics industry for components like batteries, capacitors, and electrical connections.

- Malleability and Flexibility: Nickel foil is malleable and can be easily shaped into thin sheets, which is beneficial for precision applications that require flexibility.

- Magnetic Properties: Nickel exhibits ferromagnetic properties, making it ideal for use in magnetic shielding applications and other electromagnetic devices.

- Durability and Strength: Nickel foil is tough and resistant to wear and tear, ensuring long-lasting performance in demanding applications.

-

- High Density: Exceptional density provides effective radiation shielding.

- Malleability: Easily shaped and manipulated to fit intricate forms and surfaces.

- Corrosion Resistance: Naturally resistant to most environmental and chemical effects.

- Thermal and Acoustic Insulation: Excellent properties for heat and sound dampening.

- Durability: Withstands wear and tear in harsh environments.

- Impermeability: Blocks light, moisture, and gases, making it suitable for sensitive sealing applications.