Showing 13–21 of 21 results

-

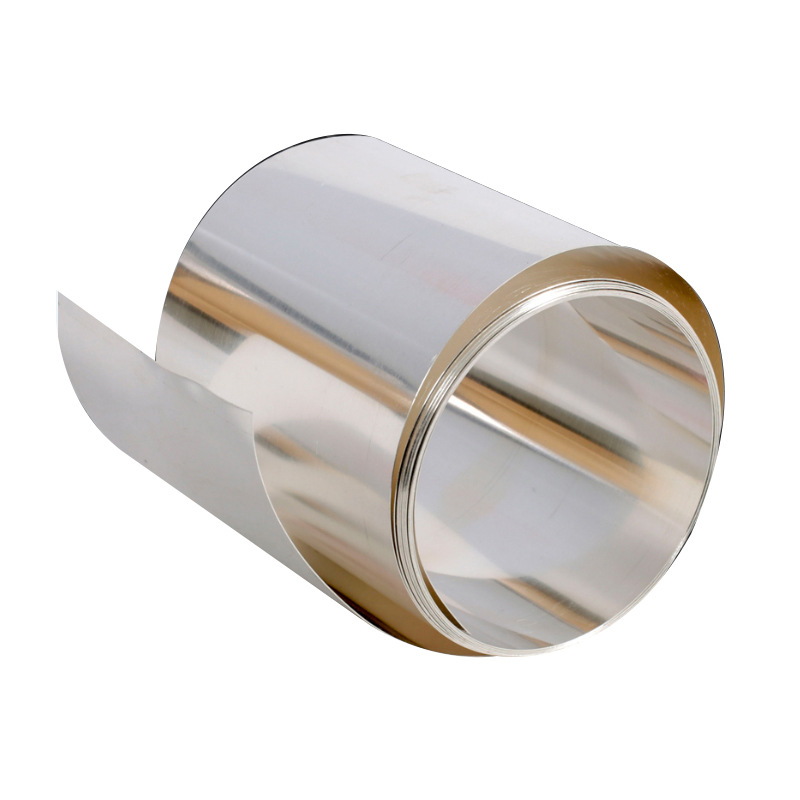

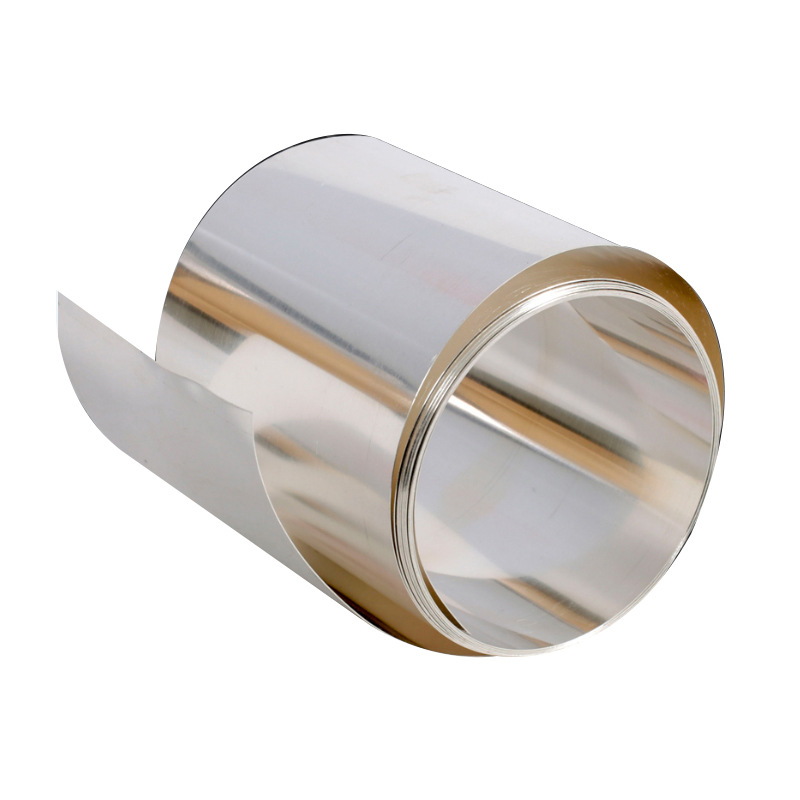

- High Melting Point: Rhenium has an extremely high melting point of 3180°C, making it ideal for use in environments with intense heat.

- Excellent Corrosion and Oxidation Resistance: Rhenium foil shows outstanding resistance to oxidation and corrosion, even at high temperatures.

- High Density and Strength: Known for its superior density and strength, rhenium foil maintains structural integrity under heavy loads and extreme temperatures.

- Thermal and Electrical Conductivity: Rhenium exhibits excellent thermal and electrical conductivity, making it suitable for high-performance applications in electronics.

- Malleability and Ductility: Despite its strength, rhenium foil can be easily processed, providing flexibility in various manufacturing processes.

-

- High Strength-to-Weight Ratio: Scandium foil offers excellent mechanical strength relative to its weight, making it a lightweight yet durable material ideal for aerospace and military applications.

- High Melting Point: Scandium has a high melting point of 1,540°C (2,804°F), providing exceptional performance in high-temperature environments.

- Corrosion Resistance: Scandium foil exhibits remarkable resistance to corrosion, especially in acidic and saline environments, making it suitable for challenging environmental conditions.

- Thermal Stability: The material maintains its mechanical properties even at elevated temperatures, ensuring long-term reliability in high-heat applications.

- Non-toxic and Biocompatible: Scandium foil is non-toxic, making it safe for medical and other applications where human exposure may occur. Its biocompatibility is also an asset for certain implantable medical devices.

- Electrical Conductivity: Although not as conductive as copper, scandium foil still offers good electrical conductivity, making it suitable for various electronic applications.

- Lightweight: Scandium is a relatively light metal, which helps reduce the weight of components and systems, particularly in aerospace and defense applications.

-

- Lightweight and Malleable: Tin foil is extremely lightweight and can be easily bent, folded, and shaped into various forms without losing its integrity.

- Corrosion Resistance: Tin is naturally resistant to corrosion, which makes it ideal for applications where exposure to moisture and air is a concern.

- Excellent Conductivity: Tin foil exhibits good electrical conductivity, which is useful in a variety of electronic applications.

- Durability and Flexibility: Tin foil combines durability with flexibility, offering both strength and ease of handling in manufacturing processes.

-

- Exceptional Corrosion Resistance: Tantalum is highly resistant to chemical attack, particularly in acidic environments, making it ideal for use in corrosive conditions.

- High Melting Point: With a melting point of 3017°C, tantalum foil can withstand extreme temperatures without losing structural integrity.

- Good Conductivity: Tantalum exhibits excellent electrical and thermal conductivity, making it suitable for high-performance electronics and heat dissipation.

- Biocompatibility: Tantalum is non-toxic and biocompatible, allowing its use in medical implants and devices.

- Ductility and Malleability: Tantalum foil is highly ductile and can be easily formed into intricate shapes without cracking, even at room temperature.

- High Purity: Our tantalum foils are available in ultra-high purity grades to meet stringent industrial and scientific requirements.

-

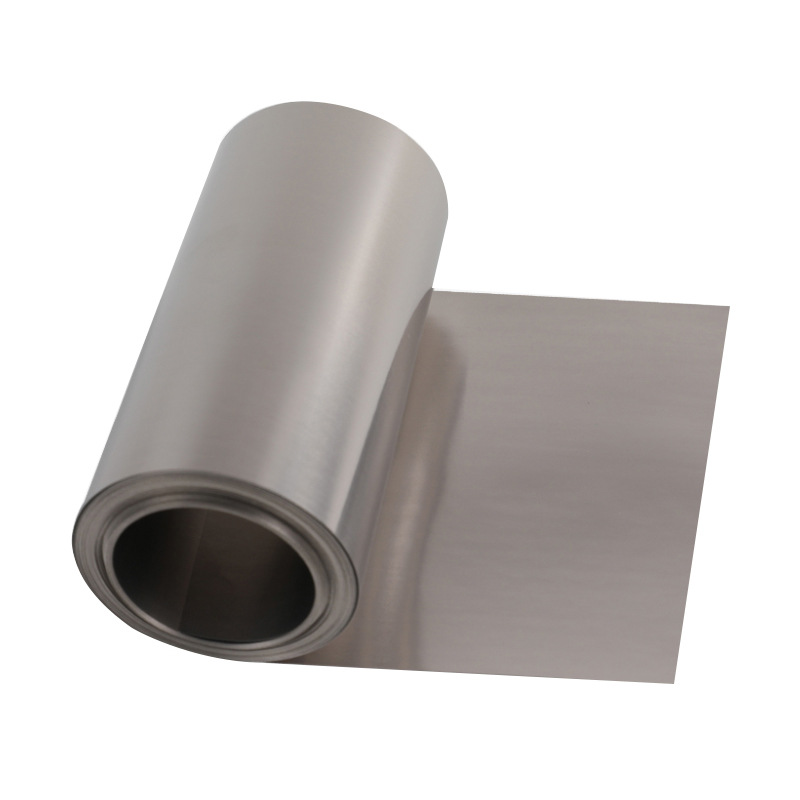

- High Strength-to-Weight Ratio: Titanium foil is known for its excellent strength-to-weight ratio, making it a lightweight yet durable material. This property is especially valuable in industries like aerospace, where minimizing weight while maintaining structural integrity is crucial.

- Corrosion Resistance: One of the standout features of titanium is its exceptional resistance to corrosion. It forms a stable oxide layer on its surface, protecting it from environmental factors such as water, air, and chemicals. This makes titanium foil ideal for use in harsh or corrosive environments.

- High-Temperature Resistance: Titanium foil can withstand high temperatures without compromising its mechanical properties. It remains strong and stable even at elevated temperatures, which is why it is used in high-performance applications like jet engines and chemical reactors.

- Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and compatible with the human body. This makes titanium foil a popular choice for medical implants and devices, as it does not cause adverse reactions in the body.

- Excellent Fatigue Resistance: Titanium foil has excellent fatigue resistance, making it suitable for applications that require materials to endure repeated stress without failure. This property is critical in aerospace, automotive, and other engineering sectors.

- Non-Magnetic: Titanium is non-magnetic, which makes titanium foil a valuable material in electronic and medical devices where magnetic interference can affect performance.

- Formability and Flexibility: Titanium foil is highly malleable and can be easily formed into various shapes. It can be rolled, stamped, or processed to meet the specific needs of different applications, making it versatile in manufacturing processes.

-

- High Strength-to-Weight Ratio: Vanadium foil is lightweight yet incredibly strong, making it suitable for aerospace and structural applications.

- Corrosion Resistance: Vanadium exhibits excellent resistance to oxidation and corrosion, especially in harsh environments.

- High Melting Point: With a melting point of 1,910°C (3,470°F), vanadium foil is highly resistant to heat, ideal for high-temperature applications.

- Ductility: Vanadium foil is ductile and can be processed into thin sheets or complex shapes without losing its structural integrity.

- Thermal and Electrical Conductivity: Vanadium offers good thermal and electrical conductivity, suitable for energy storage and electrical applications.

- Compatibility with Alloys: Vanadium can enhance the strength and wear resistance of other metals when used as an alloying element.

-

- High Melting Point: Tungsten has the highest melting point of any metal, around 3,422°C (6,192°F). This makes it perfect for high-temperature applications such as heat shields, aerospace components, and vacuum furnaces.

- Excellent Strength: Tungsten foil exhibits outstanding tensile strength, maintaining its integrity even under stress or at elevated temperatures. This property ensures that it is highly durable and reliable for demanding applications.

- Low Thermal Expansion: Tungsten has an extremely low coefficient of thermal expansion (CTE), which means it does not expand or contract significantly when subjected to temperature changes. This is crucial for applications requiring dimensional stability under fluctuating temperatures.

- High Density: With a density of approximately 19.25 g/cm³, tungsten is one of the heaviest metals, giving it excellent mass and stability for a variety of industrial uses.

- Corrosion Resistance: Tungsten is resistant to corrosion in most environments. It is particularly resistant to oxidation, making it suitable for applications in vacuum environments or where high chemical stability is required.

- Biocompatibility: Tungsten is biocompatible and is used in medical implants, surgical tools, and radiation shielding, where its non-reactive nature is a significant advantage.

-

- Corrosion Resistance: Zinc is known for its excellent corrosion resistance, especially in moist environments. It forms a protective oxide layer that shields the material from further corrosion, making it ideal for use in outdoor and harsh environmental conditions.

- Electrical Conductivity: Although not as conductive as copper or aluminum, zinc foil still offers good electrical conductivity, making it suitable for applications in electrical components, such as batteries and capacitors.

- Thermal Conductivity: Zinc has relatively high thermal conductivity, making zinc foil useful in heat dissipation applications, particularly in electronics and industrial processes where temperature control is critical.

- Malleability and Flexibility: Zinc foil is highly malleable, allowing it to be easily shaped and fabricated into thin, flexible sheets. This makes it suitable for a variety of industrial applications requiring precise material manipulation.

- Non-Toxicity and Biocompatibility: Zinc is a biocompatible metal, meaning it can be used in medical and food-related applications without adverse effects. It is also non-toxic, which adds to its safety and versatility in various industries.

- Antimicrobial Properties: Zinc has natural antimicrobial properties, making zinc foil valuable in applications where hygiene and contamination control are critical, such as in medical equipment and food packaging.

-

- High Melting Point: Zirconium foil has a melting point of approximately 1855°C, making it ideal for high-temperature applications.

- Corrosion Resistance: Exceptional resistance to corrosion, particularly in acids, alkalis, and saltwater environments, making it highly durable in harsh conditions.

- Low Neutron Absorption: Ideal for use in nuclear reactors as it exhibits low neutron absorption, contributing to its application in nuclear fuel cladding.

- Thermal Stability: Maintains structural integrity even under extreme temperature conditions, making it suitable for use in high-heat environments.

- Malleability: The material is highly malleable, allowing it to be formed into thin sheets, foils, and complex shapes without compromising its performance.

- Lightweight and Strong: Zirconium foil offers a balance of low density and high strength, making it suitable for applications where both strength and lightness are required.

- Biocompatibility: Non-toxic and biocompatible, making it suitable for use in medical and pharmaceutical applications.