Showing 1–12 of 246 results

-

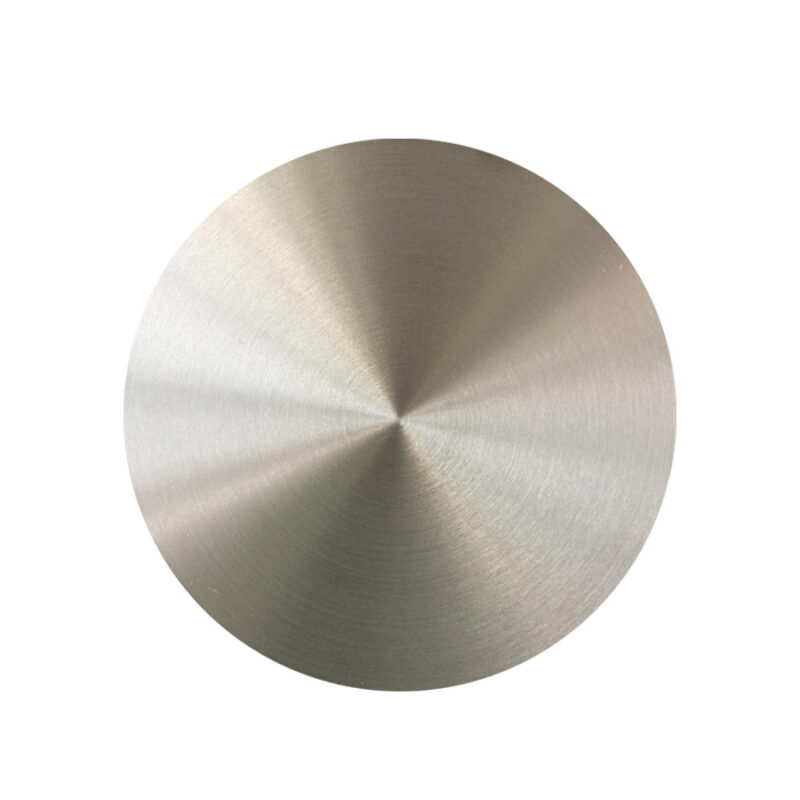

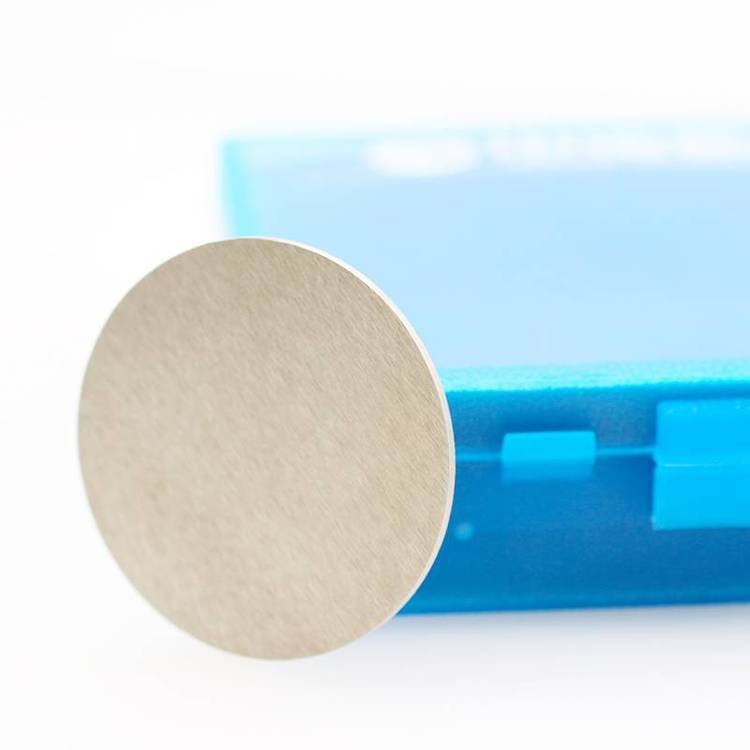

Silver (Ag) sputtering targets are used in physical vapor deposition (PVD) processes to deposit thin films of silver onto various substrates. Silver is renowned for its outstanding electrical conductivity, reflectivity, and antimicrobial properties, making it a popular choice in a wide range of industries, including electronics, optics, and healthcare.

-

- Superior Electrical Conductivity: Silver provides excellent electrical conductivity, making AgCr thin films ideal for use in electronic applications requiring efficient conduction of electricity.

- Corrosion Resistance: Chromium enhances the corrosion resistance of AgCr alloy, allowing the thin films to perform reliably in environments prone to oxidation and chemical exposure.

- Durability and Wear Resistance: The addition of chromium improves the mechanical strength and wear resistance of AgCr thin films, ensuring longer-lasting performance in various industrial applications.

- High Reflectivity: Silver’s reflective properties make AgCr thin films suitable for optical coatings where high reflectivity is desired, such as in mirrors and optical components.

- Customizable Composition: The ratio of silver to chromium in the alloy can be adjusted to tailor the properties of the thin film for specific applications, such as improving conductivity or enhancing corrosion resistance.

-

Aluminum (Al) sputtering targets are essential for industries that rely on high conductivity, reflectivity, and corrosion resistance, making them indispensable in electronics, optics, aerospace, and packaging applications.

-

- High Purity: Available in purities up to 99.999% for superior thin film quality.

- Excellent Stability: Exceptional thermal and chemical resistance for high-temperature and corrosive environments.

- Superior Hardness: Ideal for creating durable, scratch-resistant coatings.

- Dielectric Properties: High dielectric constant for microelectronic and capacitor applications.

- Consistent Performance: Engineered for uniform film deposition and low contamination levels.

-

- High Purity: Ensures consistent and reliable deposition results.

- Superior Thermal Stability: Suitable for high-temperature applications.

- Durable Films: High hardness and wear resistance in thin-film layers.

- Customizable Configurations: Available in various sizes and bonding options.

- Broad Applicability: Adaptable for diverse industrial and scientific uses.

-

- High Mechanical Strength: The combination of aluminum, chromium, cobalt, iron, and nickel in the alloy imparts excellent mechanical strength, making it ideal for thin films that require toughness and resistance to mechanical stress.

- Superior Corrosion Resistance: Chromium and nickel contribute to the alloy’s outstanding corrosion resistance, allowing thin films to perform well in corrosive environments, such as in aerospace and marine applications.

- Thermal Stability: AlCrCoFeNi alloy thin films retain their structural properties at elevated temperatures, making them suitable for high-temperature environments, such as in engines and turbines.

- Wear Resistance: Cobalt and chromium enhance the wear resistance of the alloy, making it ideal for hard coatings in industrial tools and machinery parts.

- High-Entropy Alloy Properties: As a high-entropy alloy, AlCrCoFeNi offers a unique combination of properties that cannot be achieved with traditional alloys, including high strength, toughness, and resistance to oxidation and corrosion.

-

- Good Electrical Conductivity: The combination of aluminum and copper offers excellent electrical conductivity, making it ideal for use in electronic and photovoltaic applications.

- Thermal Stability: AlCu films have excellent thermal stability, which is essential for applications in environments with varying temperatures, such as in electronics or solar cells.

- Corrosion Resistance: The alloy exhibits good resistance to corrosion, enhancing the durability and longevity of thin films.

- Low Resistance: The low resistivity of AlCu makes it ideal for interconnects and conductive layers in semiconductor and photovoltaic devices.

- High Deposition Rate: AlCu sputtering targets offer a high deposition rate, ensuring efficient production of high-quality thin films.

-

- High Thermal Conductivity: AlN offers one of the highest thermal conductivities among non-metals, which is vital for heat dissipation in high-power electronics and optoelectronics.

- Electrical Insulation: AlN is an excellent electrical insulator, making it suitable for electronic applications requiring electrical isolation with effective thermal management.

- Piezoelectric Properties: AlN exhibits strong piezoelectric properties, making it ideal for use in sensors, actuators, and acoustic wave devices.

- High Hardness and Durability: AlN films are mechanically robust, offering good wear resistance and durability for applications in harsh environments.

- Good Chemical Stability: AlN is resistant to many chemicals and environmental conditions, ensuring longevity in demanding applications.

-

- Excellent Electrical Conductivity: AlSi alloys offer good electrical conductivity, making them ideal for interconnect layers and conductive films in electronic devices.

- Thermal Stability: AlSi films exhibit high thermal stability, ensuring reliable performance in high-temperature environments, such as semiconductor processing.

- Prevention of Electromigration: The addition of silicon to aluminum helps mitigate electromigration, improving the longevity and reliability of electronic components.

- Corrosion Resistance: AlSi alloys have good resistance to oxidation and corrosion, contributing to the durability of thin films in harsh operating conditions.

- Lightweight and Strong: The lightweight nature of aluminum, combined with the added strength from silicon, makes AlSi alloys versatile in applications requiring both durability and reduced weight.

-

- Electrical Conductivity: The presence of aluminum and copper in the alloy enhances the electrical conductivity of the deposited thin films, making it ideal for semiconductor and electronic applications.

- Thermal Stability: AlSiCu alloy films exhibit excellent thermal performance, ensuring stability in high-temperature environments like semiconductor fabrication and automotive electronics.

- Mechanical Strength: Silicon contributes to the mechanical durability of the alloy, providing resistance to wear and cracking in thin films, which is essential in demanding applications.

- Corrosion Resistance: The alloy offers good resistance to corrosion, ensuring longevity in exposed environments, such as automotive electronics and solar cells.

- Customizable Size and Shape: AlSiCu sputtering targets can be produced in various forms, including discs, plates, and custom shapes, to suit different PVD systems and specific requirements.

-

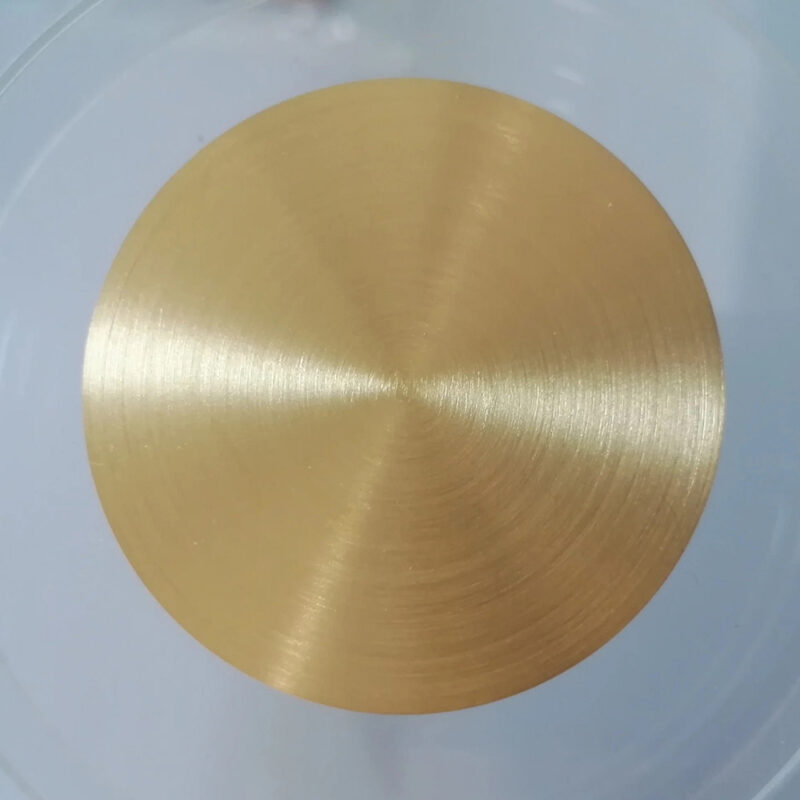

Gold (Au) sputtering target is a very important material of semiconductor, it’s used for depositing gold thin film on the surface of semiconductor chips, to form ohmic contact film, electrode or other films, it can form various metallic films system. Most of gold oxide film system can be used for manufacturing LED, microwave communication device, widely applied in spaceflight, aviation, semiconductor chips and Solar Cells.

-

- High Optical Transparency: AZO offers excellent transparency in the visible spectrum, making it ideal for applications requiring clear conductive films.

- Good Electrical Conductivity: Despite its transparency, AZO provides high electrical conductivity, which is critical in photovoltaic cells and touchscreens.

- Environmentally Friendly: Unlike ITO, AZO does not rely on scarce or expensive elements like indium, making it a more sustainable and cost-effective choice.

- Thermal and Chemical Stability: AZO films maintain stability under various temperature and environmental conditions, making them suitable for outdoor and industrial applications.

- Low Reflectivity: AZO films are known for their low reflectance, which is beneficial in display technologies to reduce glare and improve visibility.