Showing 157–165 of 165 results

-

- Thermoelectric Properties: Zn₃Sb₂ is known for its high thermoelectric efficiency, making it an excellent material for energy conversion applications.

- High Purity: Available in various purity grades, ensuring the production of high-quality thin films.

- Stable Deposition: Consistent film quality and performance, ideal for advanced manufacturing processes.

- Durability: Offers excellent thermal stability, reducing the risk of material degradation during deposition and application.

- Wide Application Range: Suitable for a variety of industries, including semiconductor, energy, and sensing technologies.

-

- High Transparency: ZnO thin films offer excellent transparency in the visible light spectrum, making them ideal for applications requiring both optical clarity and electrical conductivity.

- Good Conductivity: ZnO is a conductive oxide, providing good electrical performance in devices such as transparent electrodes and sensors.

- Wide Bandgap: ZnO is a wide-bandgap semiconductor with a bandgap of around 3.37 eV, allowing for efficient performance in UV detection and emission applications.

- Piezoelectric Properties: ZnO exhibits piezoelectric behavior, which is beneficial for applications in sensors, resonators, and energy-harvesting devices.

- Environmental Stability: ZnO thin films are chemically stable and exhibit good resistance to environmental degradation, ensuring long-term durability in various applications.

-

- Broad Transmission Range: ZnS exhibits excellent transmission in the visible, near-infrared (NIR), and mid-infrared (MWIR) regions, making it suitable for a wide range of optical applications.

- High Refractive Index: ZnS has a high refractive index, which is beneficial for designing optical coatings with precise reflection and transmission properties.

- Chemical and Thermal Stability: ZnS thin films are chemically stable and exhibit good thermal resistance, making them suitable for use in high-temperature and chemically aggressive environments.

- Infrared Transparency: ZnS is known for its excellent transparency in the infrared spectrum, especially in thermal imaging systems, laser optics, and other IR-related devices.

-

- Broad Optical Transmission: ZnSe offers high transmission from the visible to the IR range (0.6 µm to 16 µm), making it ideal for infrared optics and laser systems.

- High Laser Damage Threshold: ZnSe can withstand high-power laser radiation, making it a preferred material for CO₂ laser optics and other high-energy laser applications.

- Chemical and Thermal Stability: ZnSe is chemically stable and has good thermal shock resistance, ensuring reliable performance in challenging environments, such as thermal imaging and industrial laser systems.

- High Purity and Low Absorption: ZnSe sputtering targets are available in high purity (up to 99.999%), ensuring minimal absorption and optimal performance in optical coatings and laser optics.

-

- Optoelectronic Properties: ZnTe is highly valued for its ability to efficiently emit light, making it a key material in optoelectronics and LEDs.

- High Purity: Available in various purity levels (99.9%, 99.99%, and higher) to ensure high-quality thin films.

- Thermal Stability: ZnTe maintains its properties under high-temperature conditions, making it suitable for high-performance applications.

- Customizable Sizes: Available in different diameters and thicknesses for a wide range of sputtering systems.

- Wide Application Range: Ideal for use in numerous industries, including renewable energy, communications, and infrared sensing.

-

- High Hardness: ZrB₂ is an extremely hard material, making it ideal for wear-resistant and protective coatings.

- Thermal Stability: ZrB₂ sputtering targets produce thin films that can withstand high temperatures, making them suitable for use in harsh environments.

- High Thermal Conductivity: ZrB₂ has excellent thermal conductivity, which is advantageous for heat management in high-performance coatings.

- Chemical Resistance: ZrB₂ thin films are resistant to chemical attack, especially in high-temperature, corrosive environments.

-

- High Hardness: ZrC is known for its extreme hardness, which contributes to the durability and wear resistance of coatings.

- Excellent Thermal Conductivity: ZrC is highly conductive, making it suitable for thermal management applications.

- High Melting Point: ZrC’s melting point of approximately 3,540°C ensures that it performs well in high-temperature environments.

- Chemical Stability: ZrC films are resistant to oxidation and chemical corrosion, extending the lifespan of coated surfaces.

-

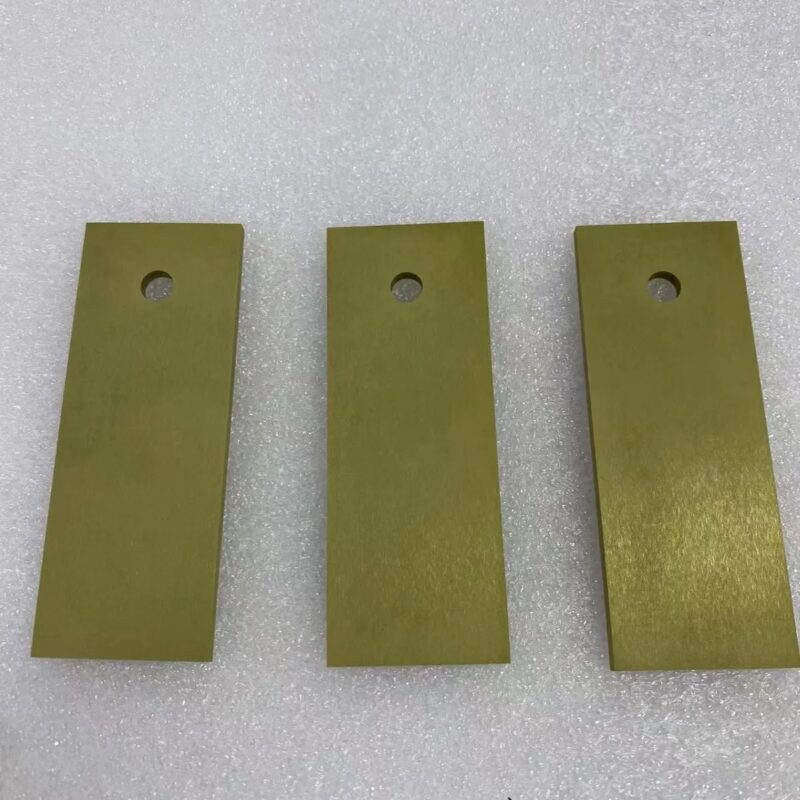

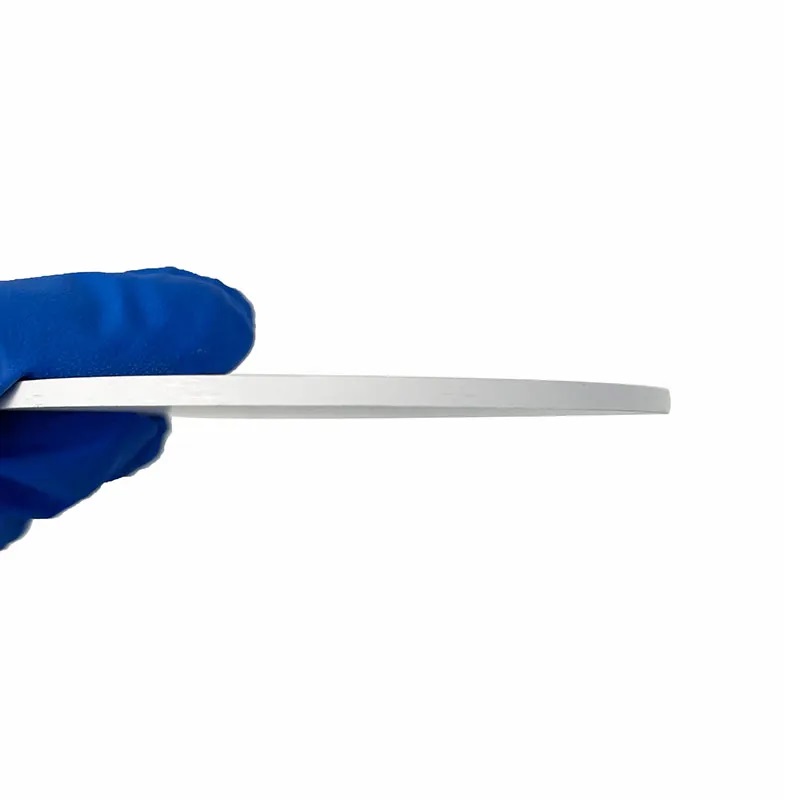

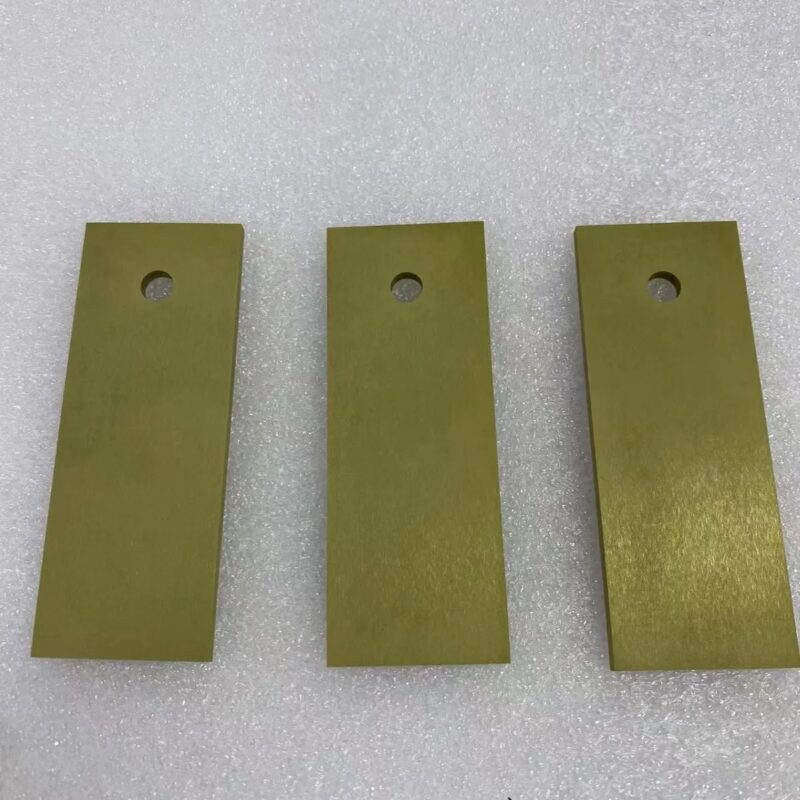

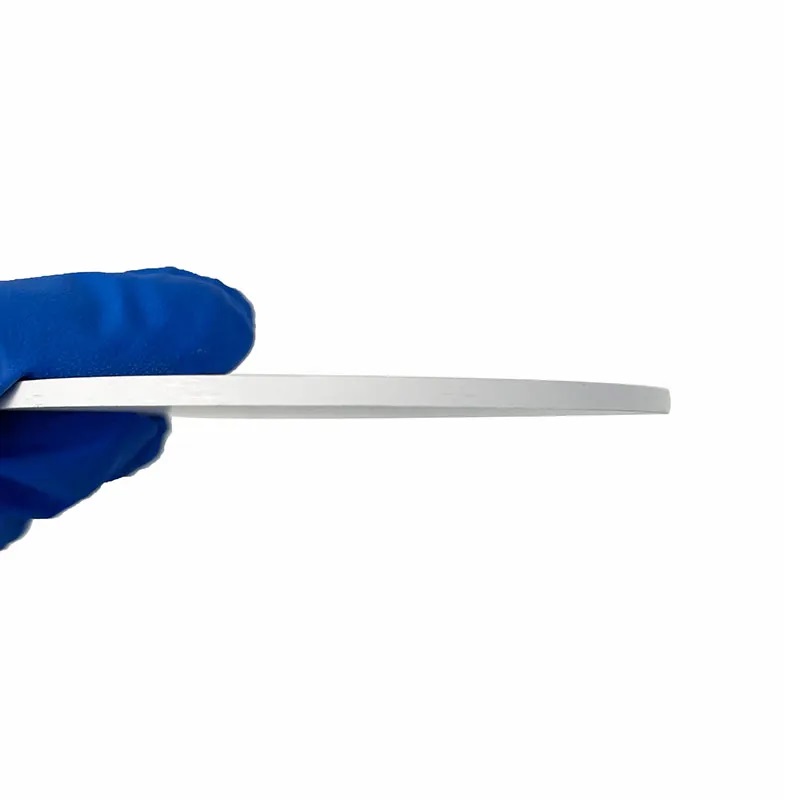

- High Hardness: ZrN films exhibit high hardness, making them ideal for protective coatings on cutting tools and wear-resistant applications.

- Corrosion and Oxidation Resistance: ZrN provides excellent resistance to chemical corrosion and oxidation, ensuring longevity and performance in harsh environments.

- Golden Color: ZrN coatings have a gold-like appearance, making them popular for decorative purposes.

- High Thermal Stability: ZrN sputtering targets produce films that can withstand high temperatures, making them suitable for aerospace and semiconductor applications.

- Good Electrical Conductivity: ZrN is electrically conductive, which allows it to be used in some electronic and microelectronic applications.

-

- High Refractive Index: ZrO₂ has a high refractive index, making it ideal for optical coatings where enhanced light control and reflection properties are needed.

- Dielectric Properties: ZrO₂ exhibits a high dielectric constant, which is critical for its use in electronic and semiconductor applications.

- Thermal Stability: ZrO₂ can withstand extreme temperatures, making it suitable for use in high-temperature coatings and thermal barrier applications.

- Wear Resistance: ZrO₂ films provide excellent hardness and wear resistance, extending the life of coated components in industrial and aerospace environments.

- Corrosion Resistance: The chemical inertness of ZrO₂ makes it resistant to corrosion, which is important in applications exposed to harsh chemicals or environmental conditions.