Showing 1–12 of 42 results

-

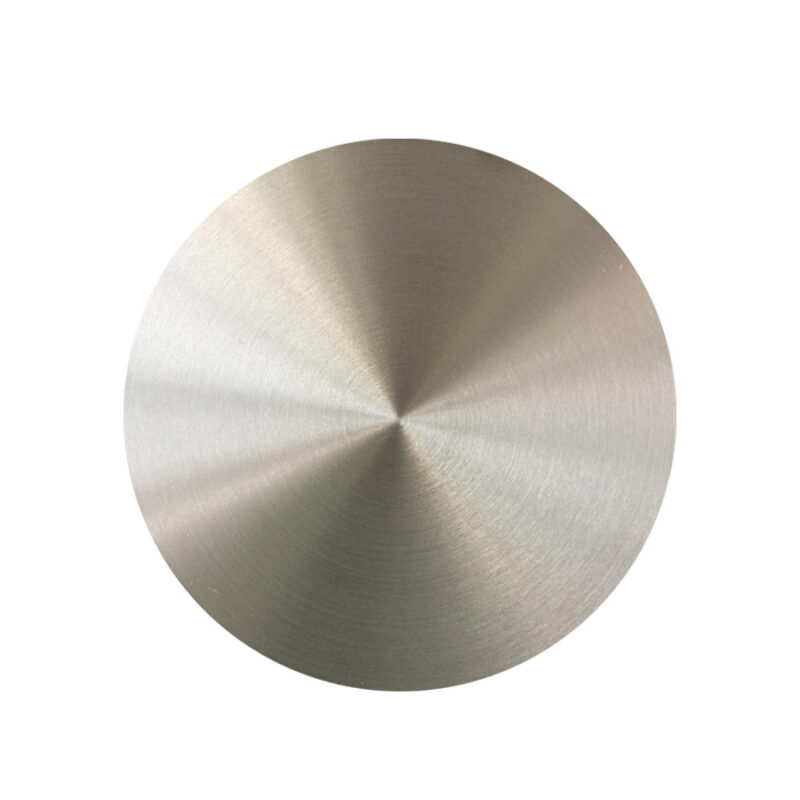

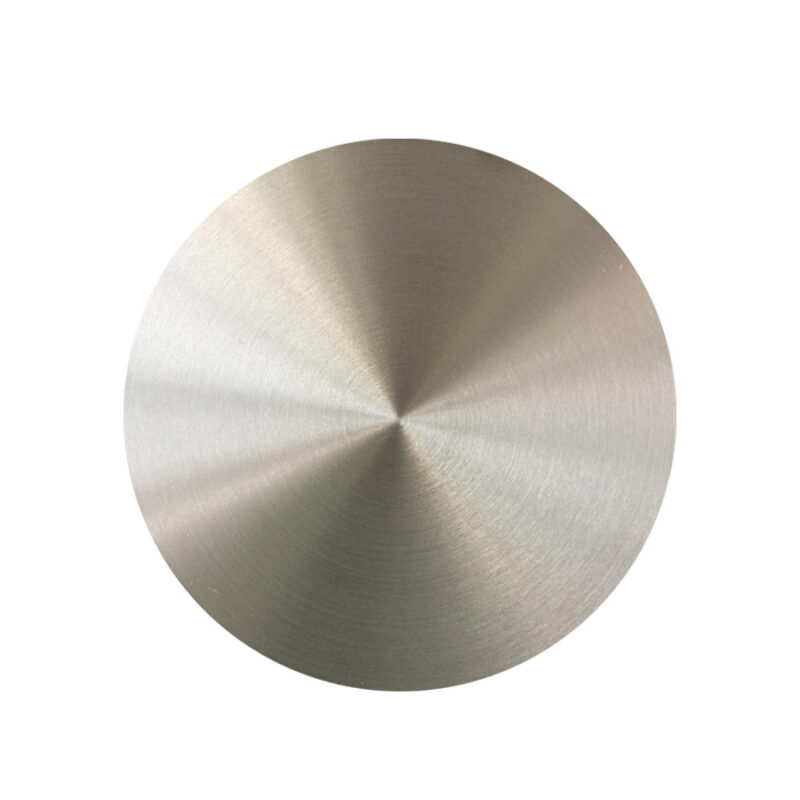

Silver (Ag) sputtering targets are used in physical vapor deposition (PVD) processes to deposit thin films of silver onto various substrates. Silver is renowned for its outstanding electrical conductivity, reflectivity, and antimicrobial properties, making it a popular choice in a wide range of industries, including electronics, optics, and healthcare.

-

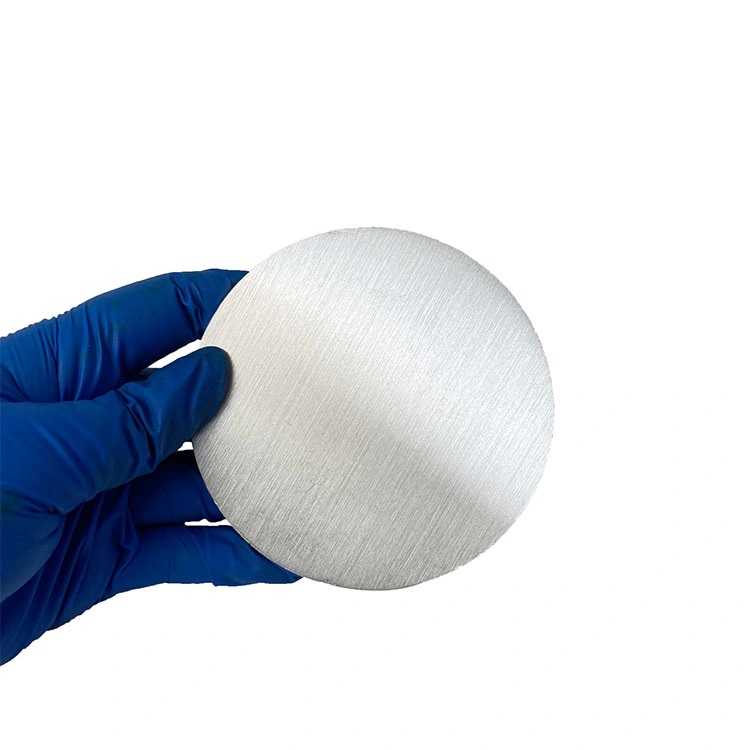

Aluminum (Al) sputtering targets are essential for industries that rely on high conductivity, reflectivity, and corrosion resistance, making them indispensable in electronics, optics, aerospace, and packaging applications.

-

$51.00 – $96.00

- Ultra-high purity 5N (99.999%) for superior film uniformity and low defect density.

- Excellent sputtering performance with stable deposition rates.

- Low impurity levels meeting research-grade and semiconductor-grade requirements.

- Standard sizes in stock for fast delivery.

- Fully customizable in purity, diameter, thickness, and shape.

-

$80.00 – $105.00

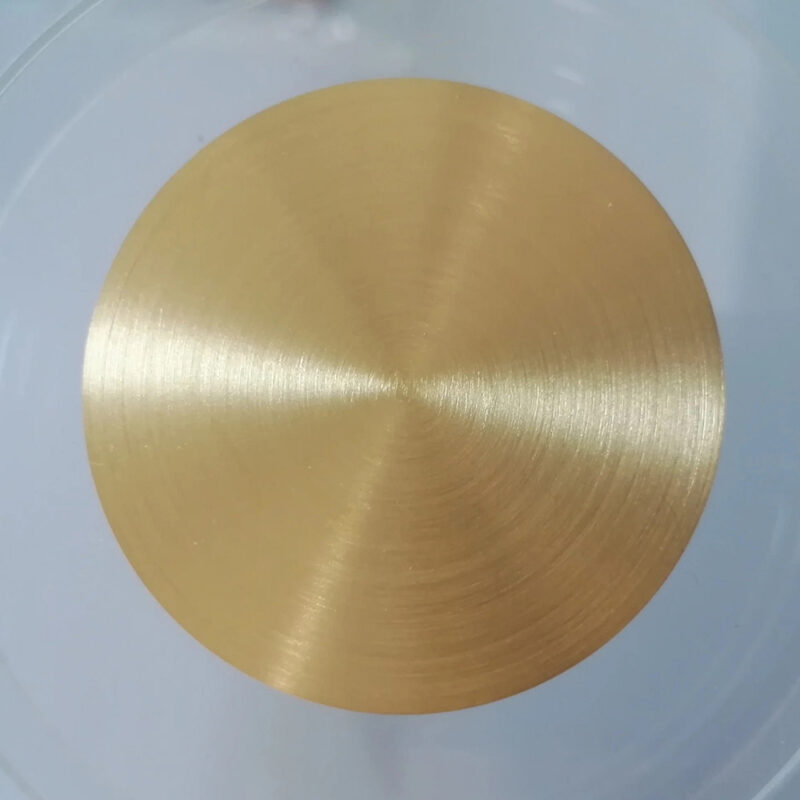

- Ultra-high purity 99.999% (5N), ensuring exceptional thin film quality and low impurity levels.

- Excellent sputtering performance, providing uniform film deposition and stable sputter rates.

- Multiple standard thickness options, including 6 mm with magnetic spacer for systems requiring enhanced magnetic coupling.

- High density and strong mechanical stability suitable for high-power sputtering systems.

- Customizable dimensions to match different sputtering equipment and process conditions.

-

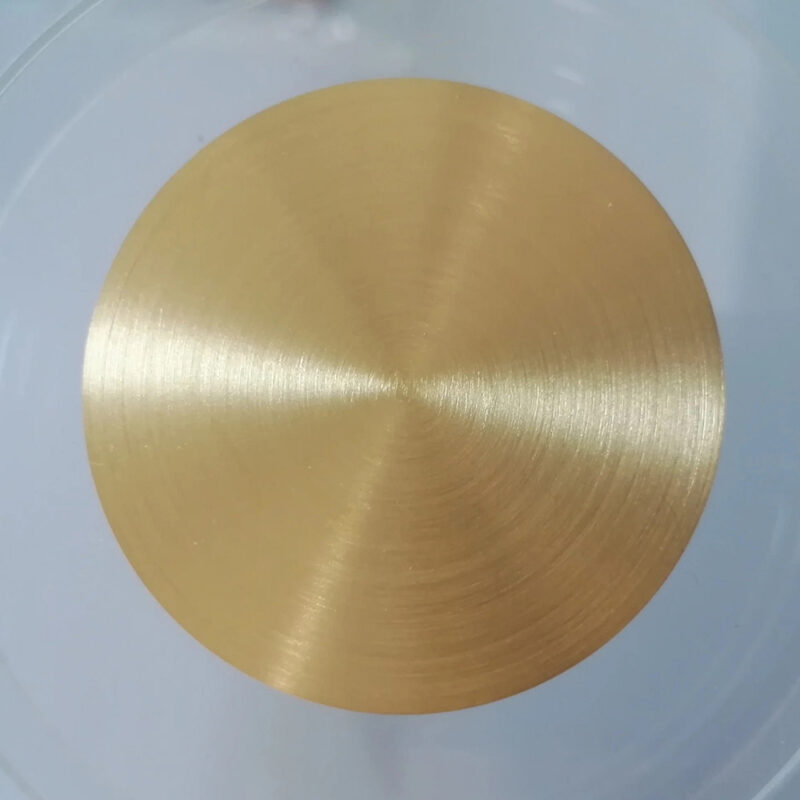

Gold (Au) sputtering target is a very important material of semiconductor, it’s used for depositing gold thin film on the surface of semiconductor chips, to form ohmic contact film, electrode or other films, it can form various metallic films system. Most of gold oxide film system can be used for manufacturing LED, microwave communication device, widely applied in spaceflight, aviation, semiconductor chips and Solar Cells.

-

Boron (B) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, particularly sputtering, to deposit thin films of boron onto various substrates. These targets are widely used in industries such as electronics, optics, and materials science due to boron’s unique properties.

-

Barium (Ba) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, particularly sputtering, to create thin films on various substrates. Barium targets are typically used in the production of optical coatings, semiconductor devices, and other advanced materials due to their unique properties.

-

Bismuth (Bi) is a unique metal known for its low toxicity, high density, and distinct electronic properties, making it valuable in specific electronic, optical, and magnetic applications. Bismuth (Bi) sputtering targets are essential for industries requiring specialized thin films with unique electronic, optical, and magnetic properties, particularly in advanced electronics, superconductors, and optical devices.

-

Calcium (Ca) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, specifically sputtering, to create thin films of calcium on various substrates. These targets are essential in various advanced technologies, including electronics, optics, and materials science, due to calcium’s unique properties.

-

- Shapes Available: Circular (disc), rectangular, and custom-designed targets.

- Diameter Range: Custom sizes available.

- Thickness: Varies depending on application requirements.

- Surface Finish: Fine-polished to ensure uniform film deposition.

- Backing Plate: Available with or without bonding to enhance thermal and mechanical stability.

-

- Purity: Available at 99.9% or higher purity to ensure optimal film quality and performance.

- Oxidation-Reduction Properties: Cerium’s ability to switch between oxidation states (Ce³⁺ and Ce⁴⁺) makes it ideal for catalytic and energy applications.

- Customizable Size and Shape: Cerium sputtering targets are available in various forms such as discs, plates, and cylinders to suit different deposition systems.

- Thermal Stability: Cerium films offer high thermal stability, making them suitable for high-temperature applications like fuel cells and catalytic converters.

-

- Purity: Cobalt sputtering targets are typically available in high purity levels, such as 99.95% (3N5) or higher, ensuring the deposition of high-quality, consistent films.

- Shapes and Sizes: These targets are available in various forms, including discs, plates, and custom shapes, to suit different sputtering systems and specific application requirements.