Showing 241–246 of 246 results

-

- Optoelectronic Properties: ZnTe is highly valued for its ability to efficiently emit light, making it a key material in optoelectronics and LEDs.

- High Purity: Available in various purity levels (99.9%, 99.99%, and higher) to ensure high-quality thin films.

- Thermal Stability: ZnTe maintains its properties under high-temperature conditions, making it suitable for high-performance applications.

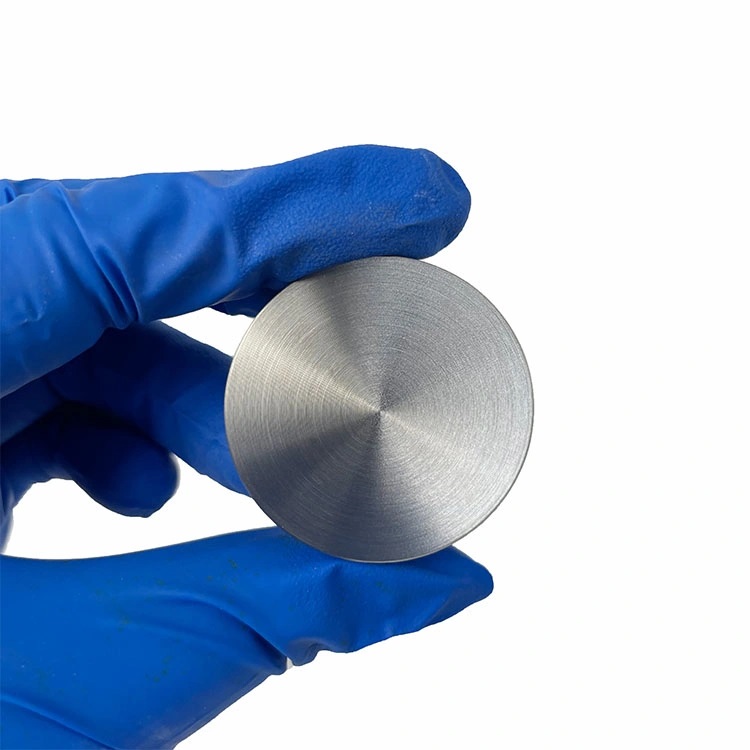

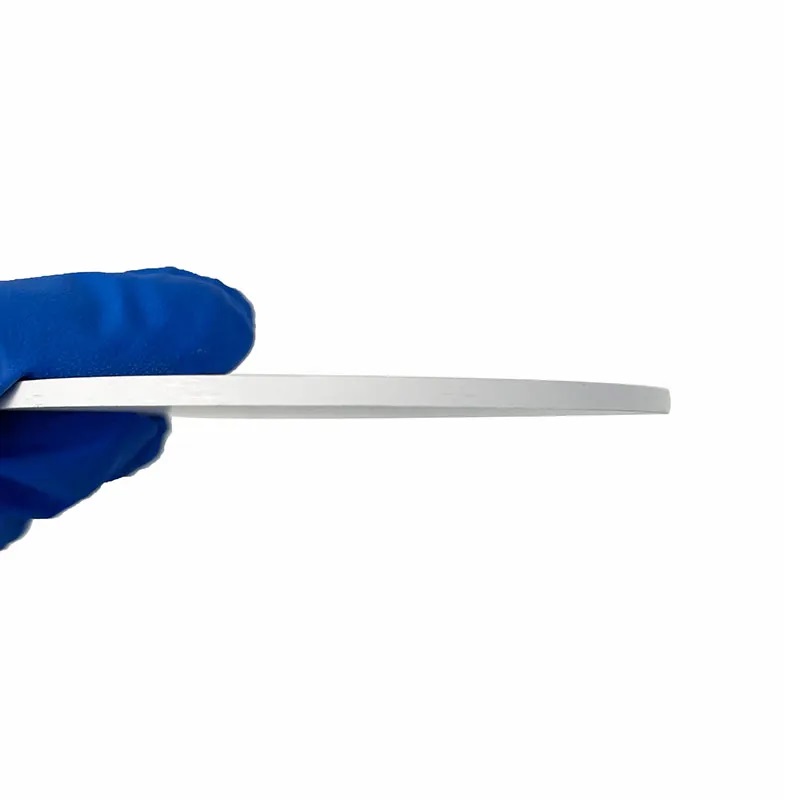

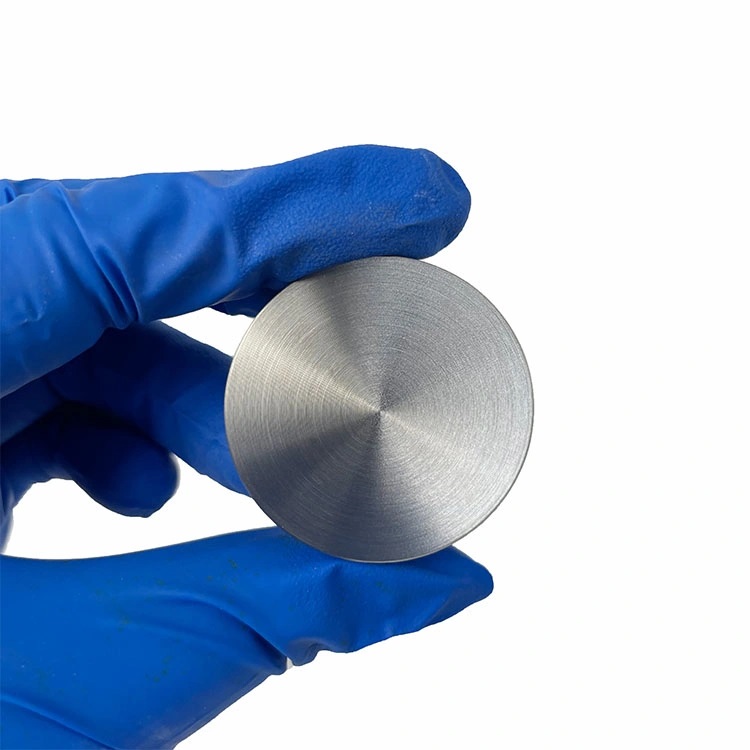

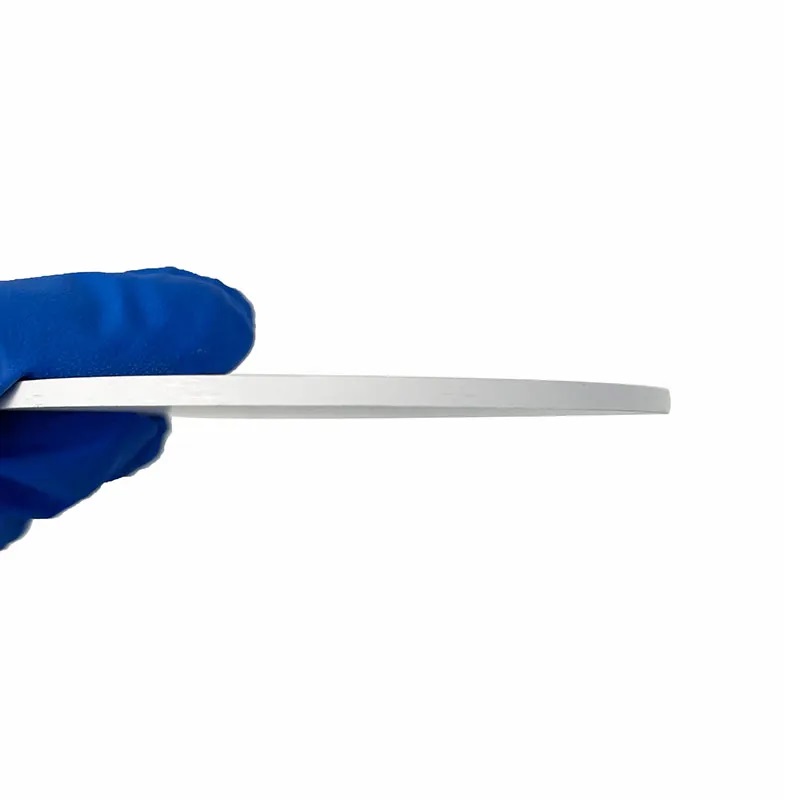

- Customizable Sizes: Available in different diameters and thicknesses for a wide range of sputtering systems.

- Wide Application Range: Ideal for use in numerous industries, including renewable energy, communications, and infrared sensing.

-

Zirconium sputtering targets are critical for industries that require materials with exceptional corrosion resistance, high-temperature stability, and biocompatibility, making them indispensable in electronics, aerospace, nuclear, and medical applications.

-

- High Hardness: ZrB₂ is an extremely hard material, making it ideal for wear-resistant and protective coatings.

- Thermal Stability: ZrB₂ sputtering targets produce thin films that can withstand high temperatures, making them suitable for use in harsh environments.

- High Thermal Conductivity: ZrB₂ has excellent thermal conductivity, which is advantageous for heat management in high-performance coatings.

- Chemical Resistance: ZrB₂ thin films are resistant to chemical attack, especially in high-temperature, corrosive environments.

-

- High Hardness: ZrC is known for its extreme hardness, which contributes to the durability and wear resistance of coatings.

- Excellent Thermal Conductivity: ZrC is highly conductive, making it suitable for thermal management applications.

- High Melting Point: ZrC’s melting point of approximately 3,540°C ensures that it performs well in high-temperature environments.

- Chemical Stability: ZrC films are resistant to oxidation and chemical corrosion, extending the lifespan of coated surfaces.

-

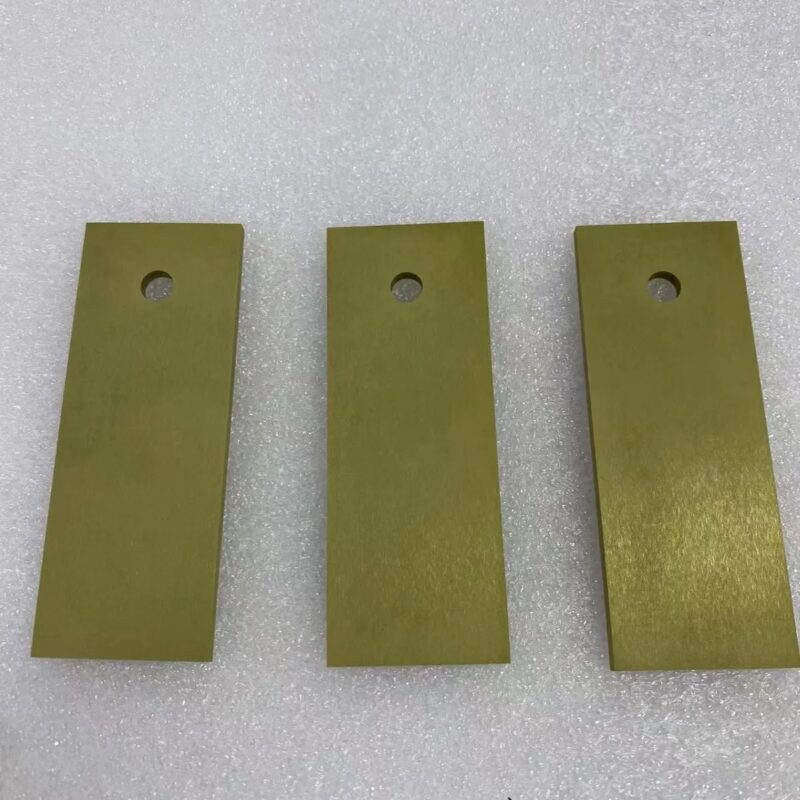

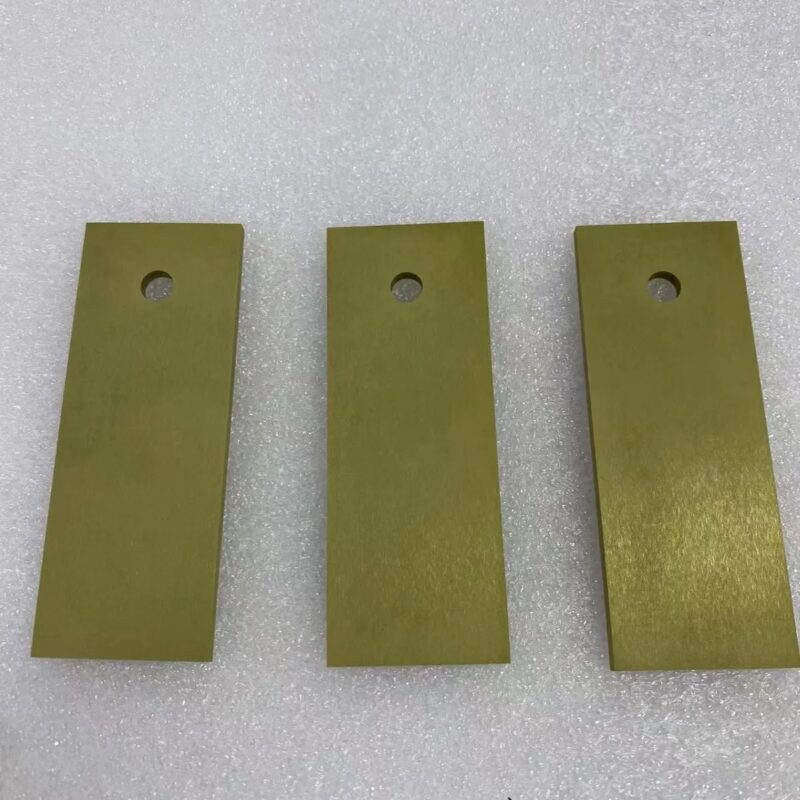

- High Hardness: ZrN films exhibit high hardness, making them ideal for protective coatings on cutting tools and wear-resistant applications.

- Corrosion and Oxidation Resistance: ZrN provides excellent resistance to chemical corrosion and oxidation, ensuring longevity and performance in harsh environments.

- Golden Color: ZrN coatings have a gold-like appearance, making them popular for decorative purposes.

- High Thermal Stability: ZrN sputtering targets produce films that can withstand high temperatures, making them suitable for aerospace and semiconductor applications.

- Good Electrical Conductivity: ZrN is electrically conductive, which allows it to be used in some electronic and microelectronic applications.

-

- High Refractive Index: ZrO₂ has a high refractive index, making it ideal for optical coatings where enhanced light control and reflection properties are needed.

- Dielectric Properties: ZrO₂ exhibits a high dielectric constant, which is critical for its use in electronic and semiconductor applications.

- Thermal Stability: ZrO₂ can withstand extreme temperatures, making it suitable for use in high-temperature coatings and thermal barrier applications.

- Wear Resistance: ZrO₂ films provide excellent hardness and wear resistance, extending the life of coated components in industrial and aerospace environments.

- Corrosion Resistance: The chemical inertness of ZrO₂ makes it resistant to corrosion, which is important in applications exposed to harsh chemicals or environmental conditions.