Showing 1–12 of 53 results

-

- High Electrical Conductivity: Excellent conductive properties due to the high silver content.

- Lightweight and Strong: Combines the strength of aluminum with the conductivity of silver, providing durable yet lightweight solutions.

- Corrosion Resistance: Superior resistance to corrosion and oxidation, ensuring longevity in demanding environments.

- Thermal Conductivity: Offers efficient heat transfer for various thermal management applications.

- Customizable Sizes: Available in a range of particle sizes to meet specific application requirements.

-

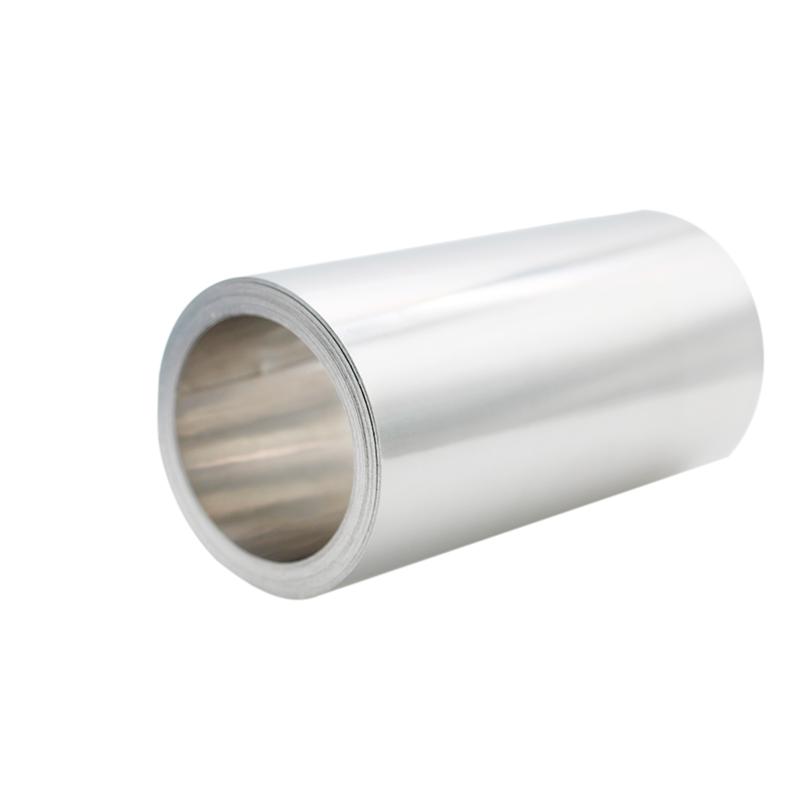

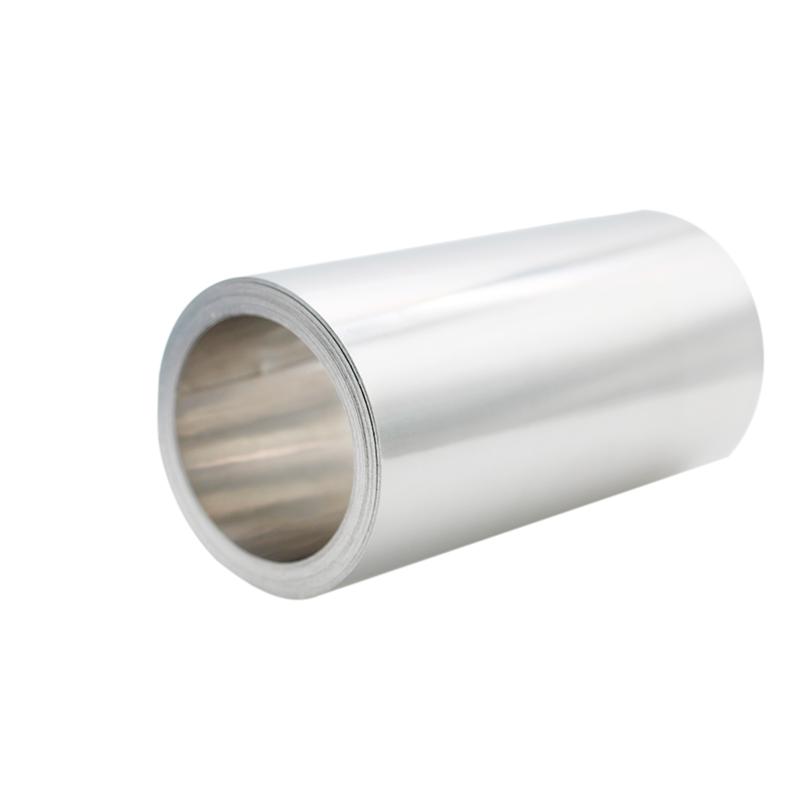

- Lightweight: Aluminium foil has a low density, making it an ideal choice for weight-sensitive applications.

- High Thermal and Electrical Conductivity: Excellent heat and electricity conduction properties make it suitable for insulation and electronic components.

- Corrosion Resistance: Aluminium foil forms a natural oxide layer that provides strong protection against corrosion.

- Ductility: Aluminium foil is highly malleable, allowing it to be formed into various shapes and sizes.

- Reflectivity: Its reflective surface helps in heat insulation and decorative applications.

-

$10.00 – $499.00

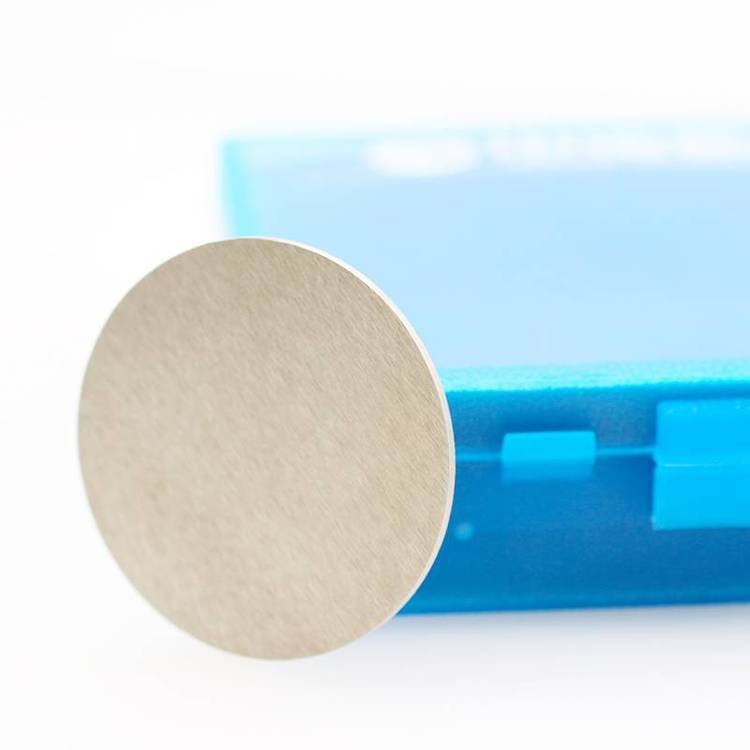

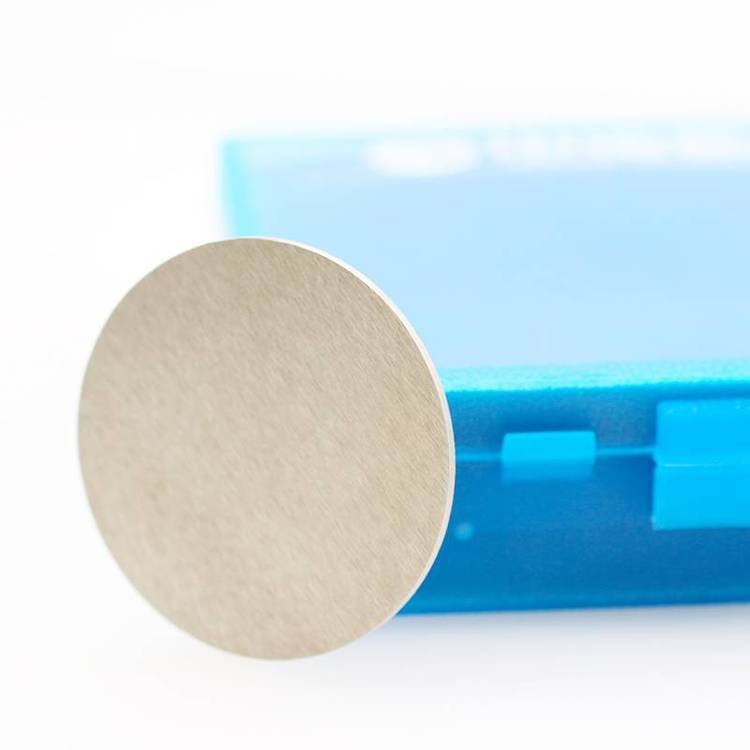

- Excellent Electrical Conductivity: Aluminum has superior electrical conductivity, making it an ideal material for thin conductive films in microelectronic devices.

- High Reflectivity: Aluminum coatings provide high reflectivity, particularly in the visible and ultraviolet (UV) regions, making it suitable for mirrors and optical coatings.

- Corrosion Resistance: Aluminum thin films form a protective oxide layer when exposed to air, providing natural corrosion resistance.

- Lightweight: As a low-density material, aluminum is preferred in applications where weight reduction is critical, such as in aerospace and automotive industries.

- Cost-Effective: Aluminum is abundant and relatively inexpensive, making it a cost-effective choice for large-scale industrial applications.

-

Aluminum (Al) sputtering targets are essential for industries that rely on high conductivity, reflectivity, and corrosion resistance, making them indispensable in electronics, optics, aerospace, and packaging applications.

-

- High Electrical Conductivity: Aluminium has about 60% of the conductivity of copper, which makes it a suitable alternative for power transmission and electrical systems, especially when the weight is a concern.

- Lightweight: Aluminium wire is much lighter than copper wire, which makes it easier to handle, transport, and install, especially in large-scale projects like power lines and electrical cables.

- Corrosion Resistance: Aluminium forms a natural oxide layer when exposed to air, which protects it from corrosion and enhances its durability in outdoor and harsh environments.

- Malleability and Ductility: Aluminium wire can be easily drawn into thin wires or bent into shapes without breaking, offering flexibility for various uses, especially in flexible cabling applications.

- Thermal Conductivity: Aluminium wire has good thermal conductivity, making it suitable for applications where heat dissipation is necessary, such as in electrical power transmission and electronic components.

- Recyclability: Aluminium is 100% recyclable, maintaining its material properties without degradation, making it a sustainable choice for industries seeking environmentally friendly solutions.

-

- High Purity: Typically ≥ 99.9%, ensuring consistent performance and minimal impurities for demanding applications.

- Thermal Stability: Withstands temperatures exceeding 1600°C, suitable for high-temperature processes.

- Chemical Resistance: Inert to most acids and alkalis, making it reliable in corrosive environments.

- Mechanical Durability: High hardness and wear resistance, ensuring longevity in abrasive and high-stress conditions.

- Electrical Properties: Excellent dielectric strength, ideal for insulating applications.

-

- High Purity: Available in purity levels up to 99.9999%, ensuring consistent performance in demanding applications.

- Exceptional Hardness: High hardness makes it suitable for abrasive and cutting applications.

- Thermal Stability: Capable of withstanding extreme temperatures, ideal for refractory and heat-resistant applications.

- Corrosion Resistance: Excellent resistance to chemical and environmental degradation.

- Electrical Insulation: Superior dielectric properties for electronic and electrical applications.

- Versatile Particle Sizes: Available in various particle sizes to meet diverse application requirements.

-

- High Purity: Available in purities up to 99.999% for superior thin film quality.

- Excellent Stability: Exceptional thermal and chemical resistance for high-temperature and corrosive environments.

- Superior Hardness: Ideal for creating durable, scratch-resistant coatings.

- Dielectric Properties: High dielectric constant for microelectronic and capacitor applications.

- Consistent Performance: Engineered for uniform film deposition and low contamination levels.

-

- High Hardness: Exhibits superior hardness, making it suitable for abrasive applications.

- Thermal Stability: Maintains integrity at elevated temperatures, ideal for high-temperature environments.

- Electrical Conductivity: Offers good electrical conductivity for certain applications.

-

- High Purity: Ensures consistent and reliable deposition results.

- Superior Thermal Stability: Suitable for high-temperature applications.

- Durable Films: High hardness and wear resistance in thin-film layers.

- Customizable Configurations: Available in various sizes and bonding options.

- Broad Applicability: Adaptable for diverse industrial and scientific uses.

-

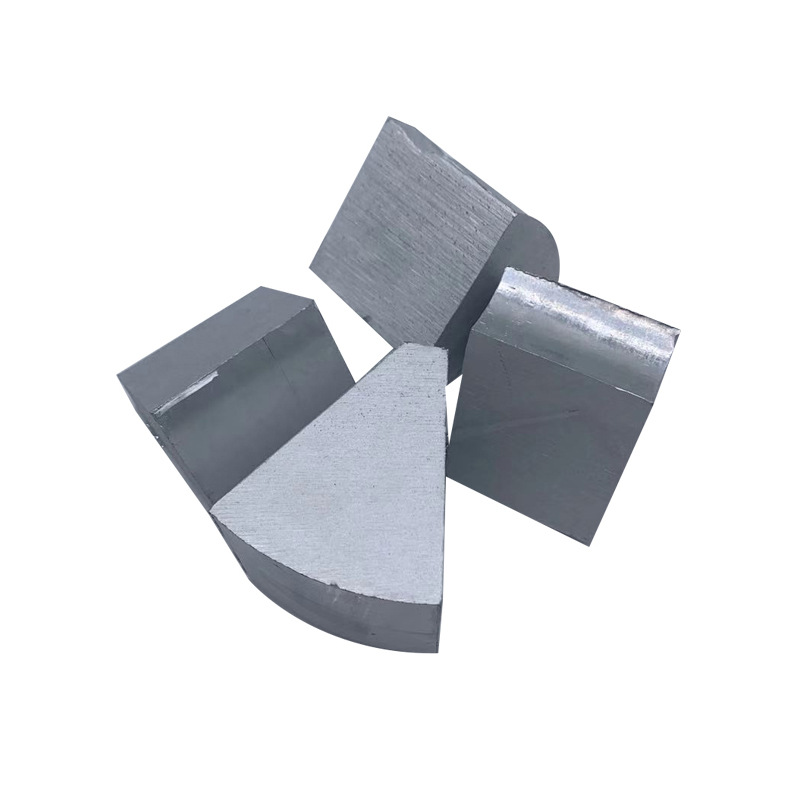

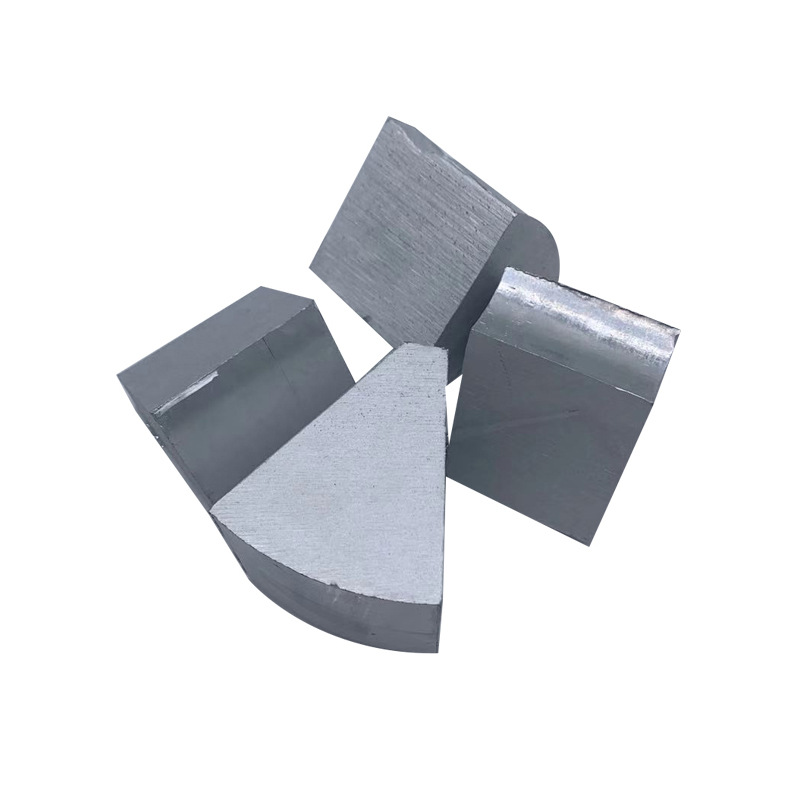

- High Mechanical Strength: The combination of aluminum, chromium, cobalt, iron, and nickel in the alloy imparts excellent mechanical strength, making it ideal for thin films that require toughness and resistance to mechanical stress.

- Superior Corrosion Resistance: Chromium and nickel contribute to the alloy’s outstanding corrosion resistance, allowing thin films to perform well in corrosive environments, such as in aerospace and marine applications.

- Thermal Stability: AlCrCoFeNi alloy thin films retain their structural properties at elevated temperatures, making them suitable for high-temperature environments, such as in engines and turbines.

- Wear Resistance: Cobalt and chromium enhance the wear resistance of the alloy, making it ideal for hard coatings in industrial tools and machinery parts.

- High-Entropy Alloy Properties: As a high-entropy alloy, AlCrCoFeNi offers a unique combination of properties that cannot be achieved with traditional alloys, including high strength, toughness, and resistance to oxidation and corrosion.

-

- Enhanced Conductivity: The copper content improves the overall electrical conductivity compared to pure aluminum.

- Reduced Electromigration: AlCu reduces the risk of electromigration, enhancing the reliability of electronic components.

- Good Thermal Conductivity: Excellent heat dissipation properties due to the copper content.

- Versatile Deposition: Suitable for various deposition techniques, including thermal evaporation and sputtering.