Showing 1–12 of 32 results

-

- High Hardness: Exhibits superior hardness, making it suitable for abrasive applications.

- Thermal Stability: Maintains integrity at elevated temperatures, ideal for high-temperature environments.

- Electrical Conductivity: Offers good electrical conductivity for certain applications.

-

- High Purity: Ensures consistent and reliable deposition results.

- Superior Thermal Stability: Suitable for high-temperature applications.

- Durable Films: High hardness and wear resistance in thin-film layers.

- Customizable Configurations: Available in various sizes and bonding options.

- Broad Applicability: Adaptable for diverse industrial and scientific uses.

-

- High Thermal Stability: With its relatively low melting point and ability to withstand high temperatures, B₂O₃ is ideal for applications that require materials to perform in extreme thermal conditions.

- Chemical Durability: Anhydrous boron oxide is highly resistant to chemical degradation, making it suitable for use in harsh environments where other materials might fail.

- Optical Clarity: Its high refractive index and excellent transparency in the UV-visible range make it perfect for use in precision optical devices.

- Purity and Consistency: At Tinsan Materials, we ensure that our B₂O₃ meets strict purity standards, offering consistent performance across all industrial applications.

- Versatility: Anhydrous boron oxide is a multifunctional material, suitable for a wide range of industries, from glass manufacturing to electronics and catalysts.

-

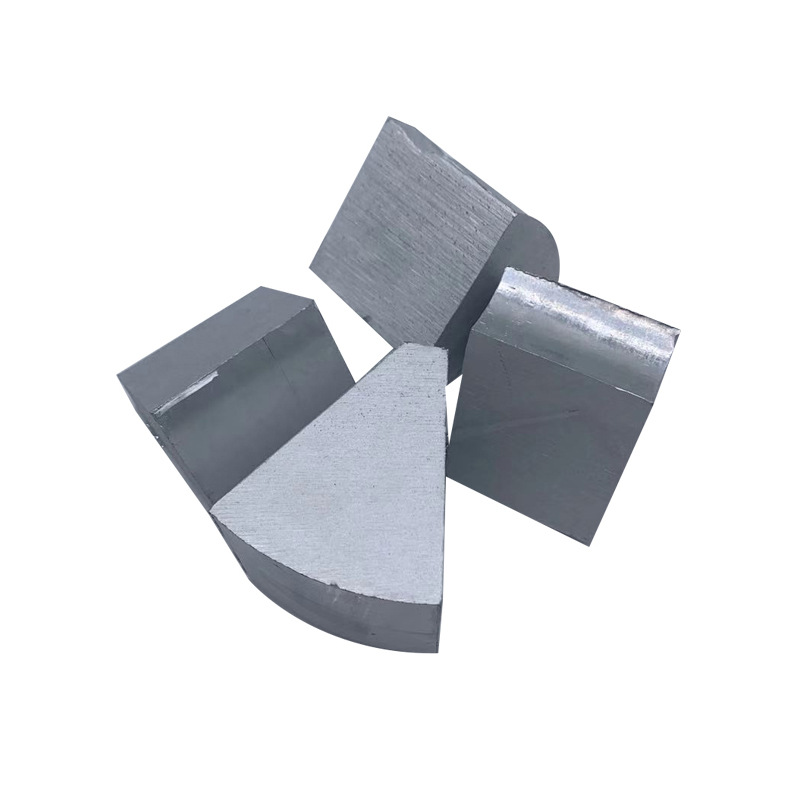

- High Hardness: Boron is extremely hard, making it ideal for applications requiring wear resistance.

- High Melting Point: Boron has a high melting point of 2,075°C, making it suitable for high-temperature deposition processes.

- Excellent Chemical Resistance: Boron is chemically inert in many environments, offering durability in corrosive conditions.

- Neutron Absorption: Boron is capable of absorbing neutrons, making it useful in nuclear shielding applications.

- Low Density: Boron is lightweight, making it suitable for applications requiring minimal mass, such as aerospace and optics.

-

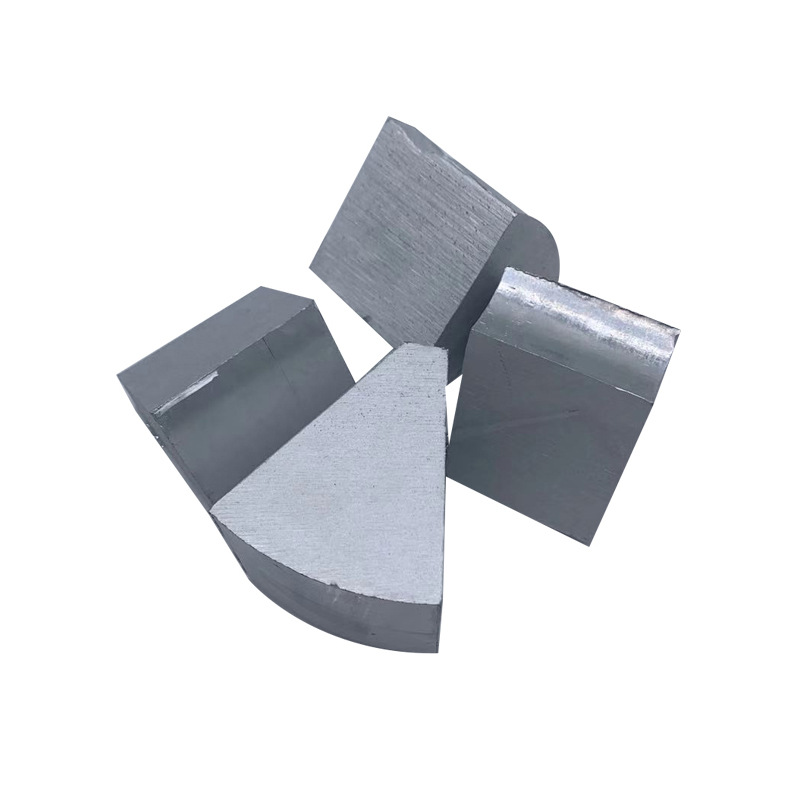

- High Melting Point: Boron has a melting point of 2,076°C, making it suitable for high-temperature applications.

- Low Density: It is lightweight compared to many metals, which makes it advantageous for use in lightweight materials and alloys.

- Hardness: Boron is extremely hard and is a key component in creating super-hard materials like boron carbide.

- Neutron Absorption: Boron’s ability to absorb neutrons without forming long-lived radioactive isotopes makes it vital for radiation shielding and nuclear control rods.

- High Thermal Conductivity: It efficiently conducts heat, which is beneficial for thermal management in electronics and other high-temperature systems.

-

Boron (B) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, particularly sputtering, to deposit thin films of boron onto various substrates. These targets are widely used in industries such as electronics, optics, and materials science due to boron’s unique properties.

-

- High Purity: Ensures optimal performance in sensitive applications.

- Thermal Stability: Maintains integrity under high-temperature conditions.

- Optical Transparency: Ideal for optical and electronic coatings.

- Versatile Uses: Applicable across industries including electronics, optics, and materials science.

- Customizable Sizes: Available in various pellet sizes to meet specific requirements.

-

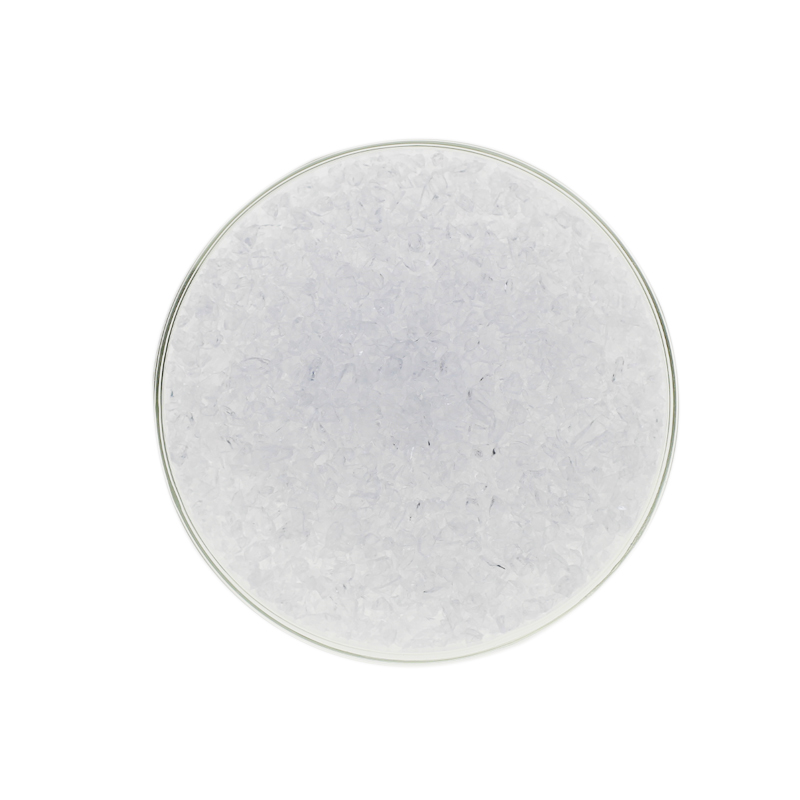

- High Purity: Available with ≥99.9% purity for consistent performance.

- Excellent Glass-Forming Properties: A key ingredient in borosilicate glass and optical fibers.

- Thermal Stability: Withstands high temperatures without decomposition.

- Chemical Inertness: Resistant to most chemicals, making it ideal for specialized applications.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) options available or customized.

- Eco-Friendly: Non-toxic and compliant with environmental standards.

-

- Extreme Hardness: Mohs hardness of 9.5, second only to diamond and cubic boron nitride.

- Low Density: Lightweight material ideal for aerospace and defense applications.

- High Thermal Stability: Exceptional performance at high temperatures.

- Chemical Inertness: Resistant to most acids and alkalis.

- Superior Wear Resistance: Ideal for abrasive and protective applications.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) grades available or customized.

-

- Exceptional Hardness: High resistance to wear and abrasion.

- Chemical Stability: Resistant to acids and alkalis, ensuring longevity in extreme environments.

- Lightweight: Facilitates applications where low weight is critical.

- High Purity: Delivers superior film quality and consistency.

-

- High Thermal Conductivity: Boron nitride exhibits excellent thermal conductivity, which helps in evenly distributing heat within the crucible, ensuring uniform melting and preventing hot spots in high-temperature applications.

- High-Temperature Resistance: BN crucibles can withstand temperatures up to 3000°C in an inert atmosphere, making them ideal for high-temperature processes like metal melting, sintering, and crystal growth.

- Chemical Inertness: BN crucibles are highly resistant to chemical corrosion, including resistance to molten metals, acids, and alkalis, making them ideal for use in aggressive chemical environments.

- Low Thermal Expansion: Boron nitride has a low coefficient of thermal expansion, which minimizes the risk of cracking and warping under thermal stress and temperature fluctuations.

- Electrical Insulation: BN possesses excellent electrical insulation properties, which can be beneficial in applications where electrical conductivity must be minimized.

- Non-Toxic and Environmentally Friendly: Unlike some other high-performance materials, boron nitride is non-toxic and environmentally safe, making it a preferred choice for many industries.

-

- High Thermal Conductivity: Excellent ability to dissipate heat, ideal for high-temperature applications.

- Electrical Insulation: Acts as an efficient insulator while maintaining high thermal conductivity.

- Chemical Stability: Resistant to chemical corrosion, oxidation, and high-temperature degradation.

- Lubrication Properties: Provides natural lubrication in extreme environments, reducing friction and wear.

- Customizable Particle Size: Available in various sizes, tailored for specific applications.