Showing 13–24 of 52 results

-

Iron (Fe Ferrum) sputtering targets are essential for industries that rely on the unique magnetic, electrical, and structural properties of iron, making them indispensable in magnetic storage, electronics, industrial coatings, and advanced material applications.

-

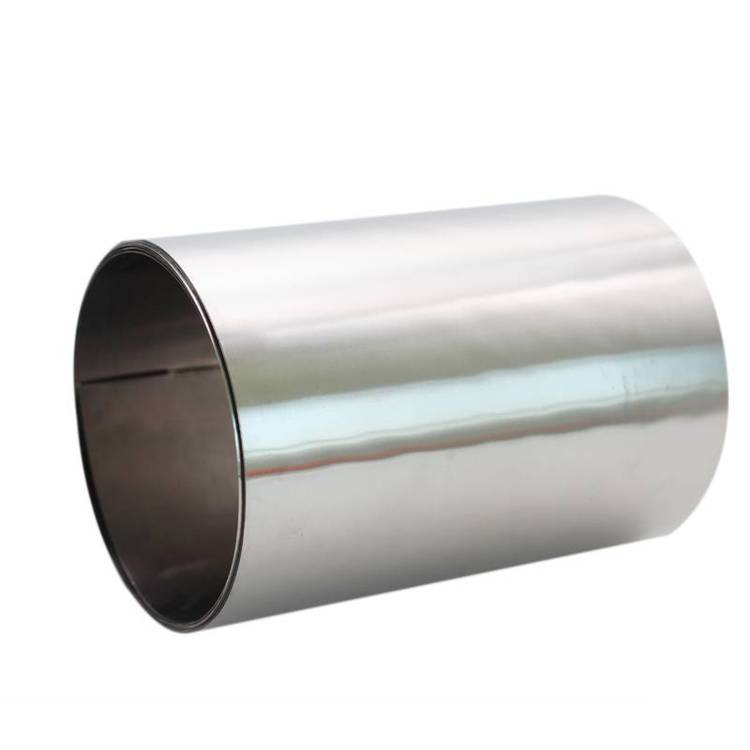

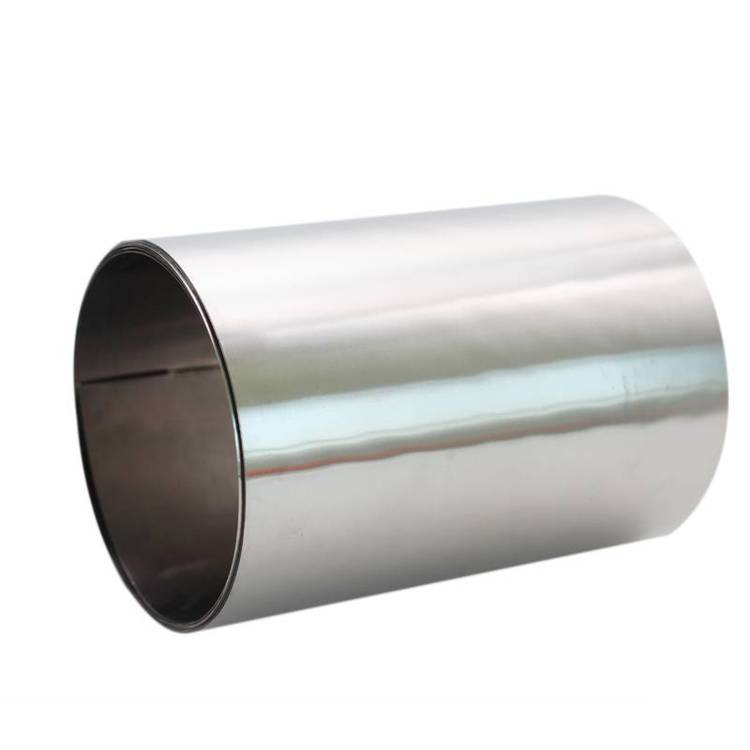

- Magnetic Properties: Iron foil possesses strong magnetic properties, making it essential for use in applications involving electromagnetism, such as transformers and electric motors.

- Strength and Durability: Iron foil is known for its strength and ability to withstand mechanical stresses, ensuring durability in industrial applications.

- Malleability and Flexibility: Iron foil is highly malleable and flexible, allowing it to be easily shaped into thin sheets, making it adaptable for various applications.

- Corrosion Resistance: While iron is generally prone to oxidation, specially treated iron foil can exhibit excellent resistance to corrosion and rust, increasing its longevity.

- Thermal Conductivity: Iron foil has moderate thermal conductivity, making it suitable for applications that require heat distribution.

- Low Cost: Iron foil is cost-effective compared to other metallic foils like gold or silver, making it an affordable solution for various applications.

-

$10.00 – $9,200.00

- High Purity: Available in 99.9% (3N) and higher purity levels to ensure the quality of thin films without contamination, essential for precision applications.

- Magnetic Properties: Fe is ferromagnetic, making it an ideal material for magnetic devices and sensors.

- Stable Evaporation: These pellets are engineered to vaporize evenly, providing consistent thin-film deposition across various substrates.

- Versatile: Suitable for both thermal and electron beam evaporation, offering flexibility for use in different vacuum deposition systems.

- High Deposition Rate: Iron pellets offer efficient evaporation, allowing for faster coating processes and uniform thin films.

-

- High Purity: Minimal impurities ensure excellent performance.

- Customizable Particle Sizes: Available in various granulations to suit different applications.

- High Density and Stability: Ideal for structural and thermal applications.

- Excellent Magnetic Properties: Suitable for electromagnetic components.

- Corrosion Resistance: Enhanced performance with additional treatments or coatings.

- Versatility: Applicable in diverse industries from manufacturing to research.

-

- High Purity: ≥99.5% purity, ensuring consistent quality and performance.

- Chemical Stability: Highly stable in both acidic and alkaline environments.

- Customizable Particle Sizes: Available in nano, micro, and custom-sized powders for diverse applications.

- Non-Toxic and Eco-Friendly: Safe for use in various environmental and industrial applications.

- Versatile: Suitable for use in a wide range of industries including paints, coatings, and water treatment.

-

- Magnetic Properties: Fe₂O₃ exhibits ferrimagnetic behavior, making it suitable for magnetic coatings and data storage applications.

- Chemical Stability: It is highly stable, corrosion-resistant, and performs well in various environmental conditions.

- High Optical Absorption: Fe₂O₃ has strong optical absorption in the visible region, which is advantageous for solar cell applications and optical filters.

- Thermal Stability: It has excellent thermal stability, allowing it to maintain its properties even at high temperatures.

- Environmental Compatibility: Fe₂O₃ is non-toxic and environmentally friendly, making it ideal for green energy applications like photocatalysis and solar cells.

-

- High Purity: Fe₂O₃ sputtering targets are available in high-purity formulations to ensure optimal thin film quality for precise applications.

- Magnetic Properties: The material exhibits ferrimagnetism, making it suitable for magnetic thin films and spintronic applications.

- Semiconductor Properties: As a semiconductor, Fe₂O₃ is used in photocatalysis and solar cells, where it can absorb sunlight and drive photoelectrochemical reactions.

- Environmental Stability: Fe₂O₃ is chemically stable and exhibits good performance in a range of environmental conditions, enhancing its use in sensors and energy applications.

-

- High Purity: Available in 99.9% (3N) and higher purity levels to ensure minimal contamination in thin-film deposition, resulting in high-performance films.

- Magnetic Properties: Fe₃O₄ is known for its ferrimagnetic behavior, which is useful in both industrial and scientific magnetic applications.

- Stable Evaporation: The pellets are designed for stable and uniform vaporization, ensuring consistent film thickness and quality during deposition.

- Versatile: Suitable for both thermal and electron beam evaporation techniques, making them adaptable for different vacuum deposition setups.

- High Density: Fe₃O₄ pellets provide dense and cohesive vapor deposition, contributing to uniform coating on the substrate.

-

- Magnetic Properties: High magnetization and excellent performance in magnetic applications.

- Chemical Stability: Resistant to corrosion and oxidation.

- Customizable Sizes: Nano to micron-scale powders available for specific needs.

- High Purity: Fe₃O₄ content ≥99.5% for consistent results.

- Eco-Friendly: Non-toxic and environmentally safe for various applications.

-

- High Purity: Guarantees consistent deposition and minimal contamination in thin films.

- Strong Magnetic Properties: Provides excellent performance in magnetic and spintronic devices.

- High Electrical Conductivity: Enhances the functionality of conductive thin films.

- Customizable Dimensions: Manufactured to meet the requirements of diverse sputtering systems.

- Versatile Material: Suitable for applications ranging from electronics to biomedical engineering.

-

- High purity (≥99.9%).

- Exceptional magnetic and chemical stability.

- Uniform pellet size for precise and consistent applications.

- Customizable sizes and specifications.

- Excellent thermal resistance and mechanical stability.

-

- High Hardness: Provides superior wear resistance for demanding applications.

- Thermal Stability: Retains mechanical and structural integrity at high temperatures.

- Corrosion and Oxidation Resistance: Performs exceptionally well in harsh and oxidative environments.

- Excellent Abrasion Resistance: Suitable for coatings and components exposed to friction and wear.

- Customizable Particle Sizes: Available in a range of sizes to suit specific requirements.