Showing 25–36 of 52 results

-

- High Hardness: Provides excellent wear resistance, making it suitable for demanding applications.

- Thermal Stability: Maintains structural integrity under high-temperature conditions.

- Customizable Composition: The carbon content can be adjusted to optimize properties for specific applications.

-

- High Entropy Alloy: The near-equal combination of five elements offers unique mechanical and thermal properties, including high strength, excellent wear resistance, and thermal stability.

- Corrosion Resistance: The alloy’s thin films offer exceptional resistance to oxidation and corrosion, even in harsh environments.

- Magnetic Properties: FeCoCrNiMn alloy sputtering targets produce films with strong magnetic properties, ideal for magnetic and electronic devices.

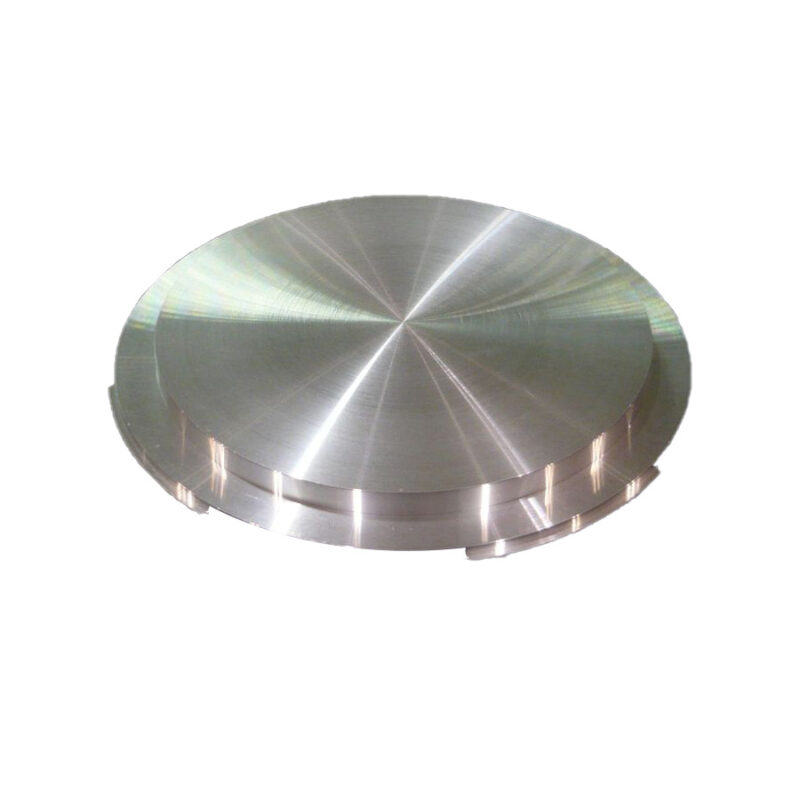

- Customizable Size and Shape: FeCoCrNiMn alloy sputtering targets are available in discs, plates, or custom shapes to meet the requirements of different deposition systems.

-

- Balanced Alloy Composition: Combines Fe, Co, Ni, Al, Cu, and Ti for superior performance.

- High Strength and Durability: Exceptional mechanical properties for demanding environments.

- Thermal Stability: Operates efficiently under extreme temperature conditions.

- Corrosion Resistance: Excellent resistance to oxidation and environmental wear.

- Magnetic Properties: Suitable for applications requiring magnetic performance.

- Customizable Particle Sizes: Available in nano and micro scales for various uses.

-

- High Magnetic Saturation: The FeCoTa alloy offers excellent magnetic properties, including high magnetic saturation and low coercivity, making it ideal for use in data storage devices and other applications requiring strong and stable magnetic fields.

- Thermal Stability: The addition of tantalum enhances the alloy’s thermal stability, allowing FeCoTa thin films to perform reliably in high-temperature environments, such as aerospace and power electronics.

- Wear Resistance: Tantalum in the alloy also contributes to increased wear resistance, ensuring that the thin films maintain their integrity under mechanical stress and prolonging their lifespan.

- Corrosion Resistance: The alloy exhibits good resistance to corrosion, making it suitable for applications in harsh or outdoor environments.

- Customizable Composition: The ratio of Fe, Co, and Ta can be adjusted to optimize magnetic and physical properties for specific applications.

-

- Corrosion Resistance: The high chromium content in FeCr alloys provides excellent resistance to corrosion, making the alloy ideal for environments exposed to moisture, chemicals, or harsh conditions.

- Magnetic Properties: FeCr alloys offer stable magnetic properties, making them suitable for use in various magnetic storage and electronic devices.

- High-Temperature Stability: FeCr thin films maintain their mechanical strength and performance even at elevated temperatures, making them useful for applications in energy, aerospace, and other industries requiring heat-resistant coatings.

- Wear Resistance: The wear resistance of FeCr thin films ensures long-lasting durability for coated components, reducing wear and tear in mechanical systems and industrial tools.

- Customizable Composition: The ratio of iron to chromium can be adjusted to optimize the properties such as corrosion resistance, magnetic performance, or wear resistance, based on the application’s specific requirements.

-

- High Oxidation Resistance: Outstanding resistance to oxidation and corrosion at high temperatures, ensuring long-term durability in harsh environments.

- High Temperature Stability: Maintains structural integrity even at temperatures exceeding 1000°C, ideal for furnace and heating applications.

- Excellent Electrical Conductivity: Offers a balance of high electrical conductivity and resistance, making it ideal for heating elements.

- Corrosion Resistance: Exhibits excellent resistance to various corrosive environments, including chemical and high-temperature exposure.

- Customizable: Available in different particle sizes and formulations to suit specific application needs.

- High Purity: Consistent high purity for reliable performance in industrial applications.

-

- Multi-Element Alloy: Balanced composition of Fe, Cu, Al, Cr, and Ni for enhanced properties.

- High Corrosion Resistance: Excellent resistance to oxidation and environmental degradation.

- Superior Mechanical Strength: Outstanding strength and durability for demanding applications.

- Thermal Stability: Maintains performance under high temperatures.

- Customizable Particle Sizes: Tailored for diverse manufacturing needs.

-

- High Magnetostriction: FeGa alloys exhibit superior magnetostrictive properties, providing enhanced performance in functional films.

- Customizable Compositions: Available in various iron-gallium ratios to meet specific application requirements.

- High Purity: Ensures consistent and reliable thin-film deposition with minimal contamination.

- Excellent Magnetic Properties: Combines strength and magnetic responsiveness for advanced thin-film applications.

- Durable and Stable: Provides robust and long-lasting performance in challenging environments.

-

- Magnetic Stability: FeHf alloys offer stable magnetic properties that make them suitable for use in a variety of magnetic devices, especially in high-temperature or harsh environments.

- Oxidation Resistance: The addition of hafnium significantly improves the alloy’s resistance to oxidation, making FeHf thin films suitable for applications exposed to elevated temperatures and oxidative conditions.

- High Strength: FeHf alloy thin films provide excellent mechanical strength, ensuring long-term durability and reliability in high-stress environments.

- Thermal Stability: FeHf alloys maintain their structural integrity and performance even at high temperatures, making them ideal for applications in electronics, aerospace, and industrial settings.

- Corrosion Resistance: The alloy’s resistance to corrosion allows it to perform well in harsh environments, protecting components from degradation due to moisture, chemicals, and other corrosive elements.

-

- Magnetic Properties: FeMn alloys exhibit useful magnetic properties, including antiferromagnetism, which makes them suitable for use in a variety of magnetic devices, sensors, and memory technologies.

- Corrosion Resistance: The alloy provides excellent resistance to corrosion, making it ideal for use in environments exposed to moisture, chemicals, and other corrosive agents.

- Wear Resistance: FeMn alloy thin films enhance the wear resistance of components, making them more durable under mechanical stress and wear, especially in industrial and mechanical applications.

- Customizable Composition: The ratio of iron to manganese can be adjusted to tailor the magnetic, mechanical, and corrosion-resistant properties of the thin films for specific applications.

- High Strength: FeMn thin films exhibit high mechanical strength, making them ideal for applications where both durability and protection are required, especially in harsh environments.

-

- Enhanced Strength: Increases the mechanical strength and wear resistance of the final product.

- Improved Corrosion Resistance: Offers better resistance to oxidation and corrosion compared to pure iron.

- Adjustable Composition: The ratio of iron to manganese can be tailored to meet specific performance requirements.

-

- High Strength-to-Weight Ratio: Combines durability with lightweight characteristics.

- Corrosion Resistance: Excellent performance in harsh environments.

- Thermal Stability: Maintains properties at elevated temperatures.

- Versatile Applications: Compatible with additive manufacturing, coatings, and traditional metallurgy.

- Customizable Composition: Tailored to meet specific project requirements.