Showing 1–12 of 47 results

-

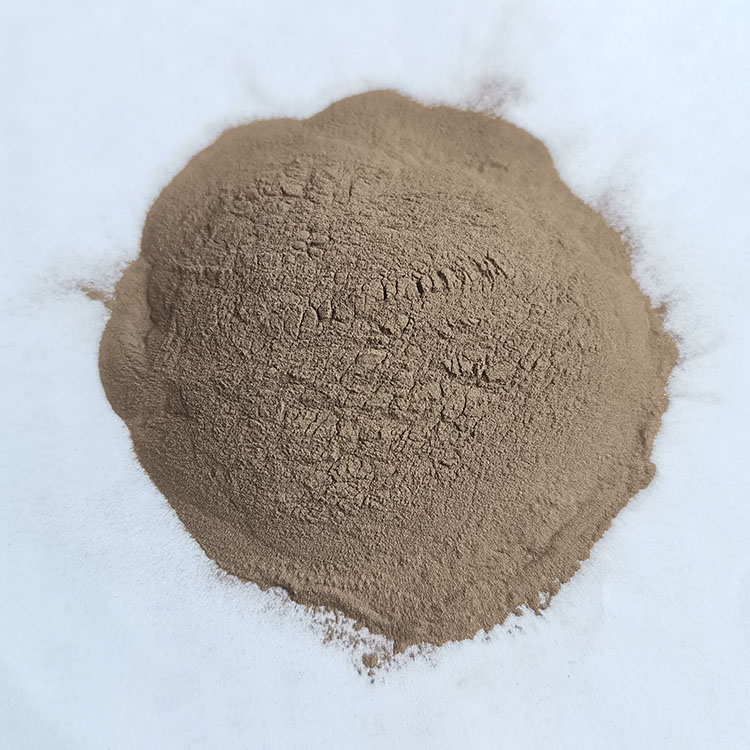

- High Strength-to-Weight Ratio: Combines the lightweight benefits of aluminum with the strength of iron.

- Thermal Stability: Resistant to high temperatures, making it ideal for demanding environments.

- Corrosion Resistance: Excellent performance in corrosive conditions.

- Customizable Particle Sizes: Suitable for diverse manufacturing processes.

- High Purity: Ensures consistent quality and performance.

- Excellent Alloying Properties: Compatible with various manufacturing techniques like powder metallurgy and additive manufacturing.

-

- Enhanced Strength: The iron content provides increased mechanical strength compared to pure aluminum.

- Corrosion Resistance: Improved corrosion resistance, making it suitable for harsh environments.

- Magnetic Properties: Offers magnetic characteristics beneficial for specific electronic applications.

- Versatile Deposition Techniques: Compatible with various deposition methods, including thermal evaporation and sputtering.

-

- High Strength-to-Weight Ratio: Combines lightweight characteristics with robust mechanical properties.

- Excellent Wear Resistance: Ensures durability in high-stress environments.

- Corrosion and Oxidation Resistance: Performs reliably in extreme chemical or thermal conditions.

- Uniform Microstructure: Enhances performance consistency across applications.

- Wide Applicability: Suitable for 3D printing, surface coatings, and high-performance components.

-

- High Purity: ≥ 99.9% purity ensures high-quality thin films with precise optical and magnetic properties.

- Superior Magneto-Optical Performance: Provides excellent Faraday rotation and low optical loss.

- Stable Composition: Chemically stable and reliable for prolonged usage.

- Customizability: Available in various shapes, sizes, and thicknesses to fit specific sputtering systems.

- Compatibility: Suitable for both RF and DC magnetron sputtering methods.

-

- High Saturation Magnetization: CoFe alloys exhibit one of the highest saturation magnetizations among magnetic materials, making them ideal for magnetic storage and sensor applications.

- Excellent Permeability: The alloy’s high permeability enables efficient magnetic performance, particularly in devices requiring soft magnetic properties with minimal energy loss.

- Low Coercivity: CoFe films have low coercivity, which is beneficial for reducing power losses in magnetic components and enhancing the performance of thin-film magnetic sensors and data storage devices.

- Corrosion Resistance: CoFe alloys possess good resistance to oxidation and corrosion, extending the longevity of thin-film applications in harsh environments.

- Customizable Composition: The ratio of cobalt to iron can be adjusted to fine-tune magnetic properties and optimize the sputtering target for specific applications.

-

- High Magnetic Saturation: Offers strong magnetic performance, making it suitable for a range of electromagnetic applications.

- Durability: Provides good mechanical strength and resistance to wear and corrosion.

- Versatile: Can be used in various thin-film deposition techniques for diverse applications.

-

- High Magnetic Moment: CoFeB alloy exhibits a high magnetic moment, making it ideal for applications requiring strong magnetic fields, such as data storage and magnetic sensors.

- Soft Magnetic Properties: The addition of boron to the CoFe alloy improves the soft magnetic properties, reducing coercivity and allowing for efficient magnetization with minimal energy loss.

- Low Coercivity: CoFeB films have very low coercivity, contributing to higher energy efficiency and better performance in magnetic thin films and devices.

- Thermal Stability: CoFeB exhibits excellent thermal stability, maintaining its magnetic properties at elevated temperatures, making it suitable for high-performance applications.

- Tunneling Magnetoresistance (TMR): CoFeB is widely used in magnetic tunneling junctions due to its ability to produce a high tunneling magnetoresistance effect, improving the performance of MRAM and spintronic devices.

-

- Excellent Magnetic Properties: High saturation magnetization and low coercivity for efficient magnetic performance.

- Thermal Stability: Maintains magnetic properties under high-temperature conditions.

- Low Magnetostriction: Ensures minimal distortion in magnetic fields for precision applications.

- Customizable Composition: Available with tailored Co, Fe, and B ratios to meet specific needs.

- Versatile Particle Sizes: Suitable for nanometer to micrometer applications.

-

- High Electrical Conductivity: Retains copper’s excellent conductive properties.

- Mechanical Strength: Enhanced by the inclusion of iron, making it suitable for robust applications.

- Customizable Composition: Various Cu-Fe ratios tailored to specific industrial needs.

- Corrosion Resistance: Provides protection against oxidation and wear.

- Uniform Particle Size: Ensures consistency in manufacturing processes.

-

Iron (Fe Ferrum) sputtering targets are essential for industries that rely on the unique magnetic, electrical, and structural properties of iron, making them indispensable in magnetic storage, electronics, industrial coatings, and advanced material applications.

-

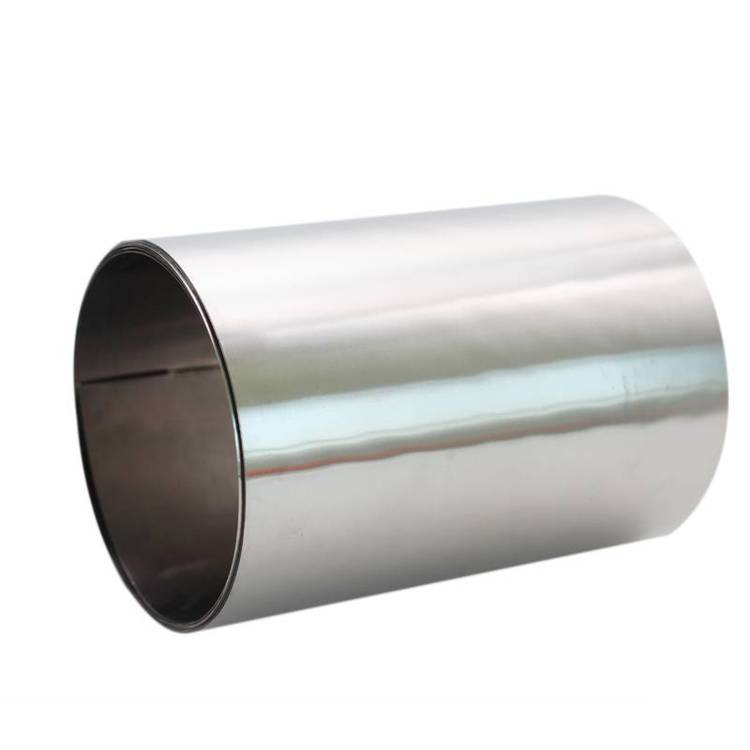

- Magnetic Properties: Iron foil possesses strong magnetic properties, making it essential for use in applications involving electromagnetism, such as transformers and electric motors.

- Strength and Durability: Iron foil is known for its strength and ability to withstand mechanical stresses, ensuring durability in industrial applications.

- Malleability and Flexibility: Iron foil is highly malleable and flexible, allowing it to be easily shaped into thin sheets, making it adaptable for various applications.

- Corrosion Resistance: While iron is generally prone to oxidation, specially treated iron foil can exhibit excellent resistance to corrosion and rust, increasing its longevity.

- Thermal Conductivity: Iron foil has moderate thermal conductivity, making it suitable for applications that require heat distribution.

- Low Cost: Iron foil is cost-effective compared to other metallic foils like gold or silver, making it an affordable solution for various applications.

-

$10.00 – $9,200.00

- High Purity: Available in 99.9% (3N) and higher purity levels to ensure the quality of thin films without contamination, essential for precision applications.

- Magnetic Properties: Fe is ferromagnetic, making it an ideal material for magnetic devices and sensors.

- Stable Evaporation: These pellets are engineered to vaporize evenly, providing consistent thin-film deposition across various substrates.

- Versatile: Suitable for both thermal and electron beam evaporation, offering flexibility for use in different vacuum deposition systems.

- High Deposition Rate: Iron pellets offer efficient evaporation, allowing for faster coating processes and uniform thin films.