Showing 1–12 of 14 results

-

- High Entropy Alloy: The near-equal combination of five elements offers unique mechanical and thermal properties, including high strength, excellent wear resistance, and thermal stability.

- Corrosion Resistance: The alloy’s thin films offer exceptional resistance to oxidation and corrosion, even in harsh environments.

- Magnetic Properties: FeCoCrNiMn alloy sputtering targets produce films with strong magnetic properties, ideal for magnetic and electronic devices.

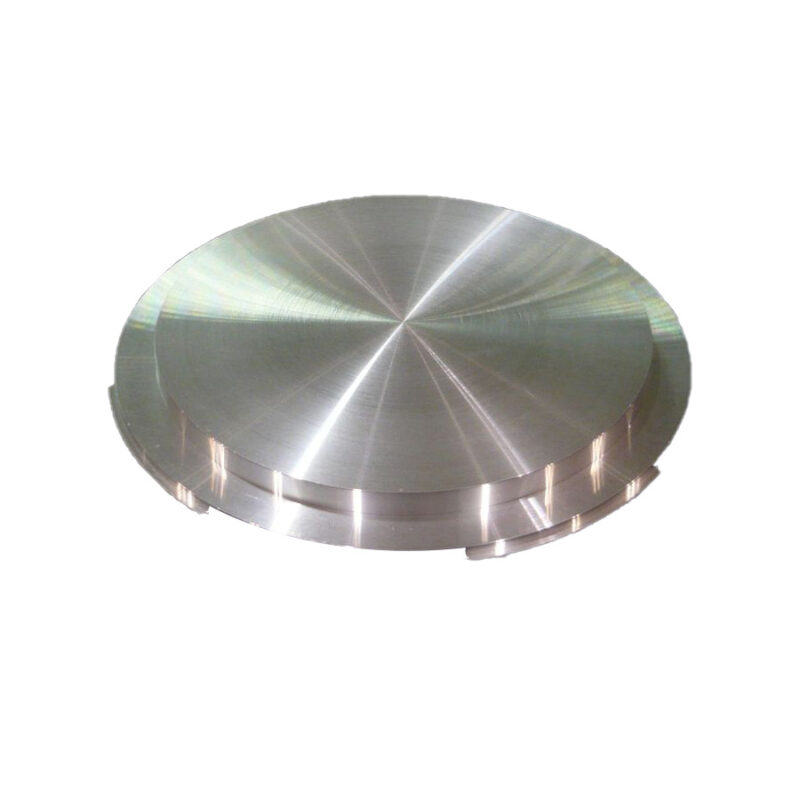

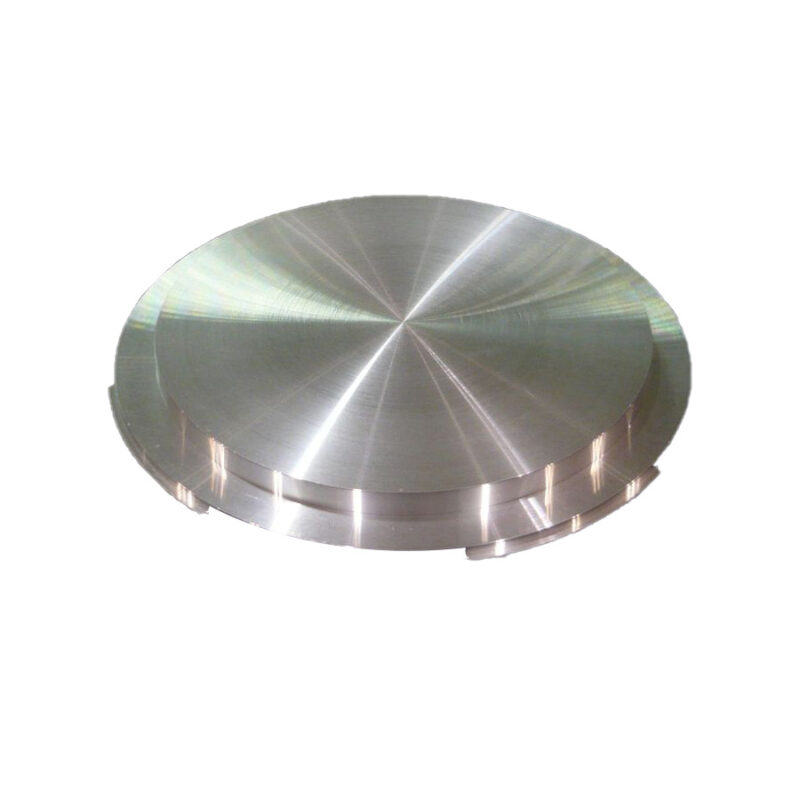

- Customizable Size and Shape: FeCoCrNiMn alloy sputtering targets are available in discs, plates, or custom shapes to meet the requirements of different deposition systems.

-

- Magnetic Properties: FeMn alloys exhibit useful magnetic properties, including antiferromagnetism, which makes them suitable for use in a variety of magnetic devices, sensors, and memory technologies.

- Corrosion Resistance: The alloy provides excellent resistance to corrosion, making it ideal for use in environments exposed to moisture, chemicals, and other corrosive agents.

- Wear Resistance: FeMn alloy thin films enhance the wear resistance of components, making them more durable under mechanical stress and wear, especially in industrial and mechanical applications.

- Customizable Composition: The ratio of iron to manganese can be adjusted to tailor the magnetic, mechanical, and corrosion-resistant properties of the thin films for specific applications.

- High Strength: FeMn thin films exhibit high mechanical strength, making them ideal for applications where both durability and protection are required, especially in harsh environments.

-

- Enhanced Strength: Increases the mechanical strength and wear resistance of the final product.

- Improved Corrosion Resistance: Offers better resistance to oxidation and corrosion compared to pure iron.

- Adjustable Composition: The ratio of iron to manganese can be tailored to meet specific performance requirements.

-

- High Strength-to-Weight Ratio: Combines durability with lightweight characteristics.

- Corrosion Resistance: Excellent performance in harsh environments.

- Thermal Stability: Maintains properties at elevated temperatures.

- Versatile Applications: Compatible with additive manufacturing, coatings, and traditional metallurgy.

- Customizable Composition: Tailored to meet specific project requirements.

-

- Antiferromagnetic Properties: IrMn alloy thin films exhibit strong antiferromagnetic behavior, which is essential for magnetic pinning in spintronic devices and memory storage.

- High Corrosion Resistance: Iridium provides excellent corrosion resistance, ensuring the durability and longevity of the deposited thin films, even in harsh environments.

- Thermal Stability: IrMn alloy films are thermally stable, making them ideal for high-temperature applications in electronic and magnetic devices.

- Customizable Size and Shape: IrMn sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit a wide range of deposition systems.

-

- Lightweight: Offers a lower density compared to other metals, making it suitable for applications where weight is a concern.

- Enhanced Strength: The combination of magnesium and manganese improves mechanical strength and durability.

- Corrosion Resistance: Provides good resistance to oxidation and corrosion, enhancing the longevity of components.

-

- High Purity: Manganese pellets are available in high purity levels, typically ≥ 99.5%, ensuring precise and consistent film quality.

- Uniform Shape: Pellets are designed for smooth and uniform evaporation, providing consistent thin film deposition.

- Good Hardness and Strength: Manganese films contribute to increased surface hardness and wear resistance.

- Magnetic Properties: Useful for applications requiring magnetic thin films or for enhancing magnetic properties in alloys.

-

Manganese (Mn) sputtering targets are essential for industries that rely on magnetic properties, wear resistance, and corrosion resistance, making them indispensable in electronics, magnetic storage, metallurgy, and catalytic applications.

-

- High Purity: Ensures consistent performance in industrial applications requiring low impurity levels.

- Thermal Stability: Excellent stability under high-temperature conditions, suitable for demanding applications.

- Catalytic Properties: Effective as a catalyst or catalyst precursor in chemical reactions.

- Versatile Applications: Suitable for ceramics, metallurgy, batteries, and chemical processes.

- Customizable Particle Sizes: Available in various particle size distributions to meet specific processing needs.

- Environmentally Friendly: Supports eco-friendly processes in industries like green energy and pollution control.

-

- Excellent Oxidizing Properties: MnO2 is known for its strong oxidizing capabilities, which are beneficial in catalysis and energy applications.

- Good Electrical Conductivity: It offers good conductivity in thin-film applications, making it suitable for use in electronic and energy-related devices.

- Versatile Deposition: MnO2 thin films can be used in a wide range of applications, from optics to electronics.

- Chemical Stability: Manganese dioxide is chemically stable, ensuring long-lasting performance in harsh environments.

- High Melting Point: Suitable for high-temperature evaporation processes.

-

- High Purity: Ensures reliability in applications requiring minimal impurities.

- Exceptional Oxidizing Properties: Effective in redox reactions and chemical processes.

- Thermal and Chemical Stability: Performs well under challenging environmental and industrial conditions.

- Versatile Applications: Suitable for use in batteries, ceramics, pigments, and catalysis.

- Customizable Specifications: Available in various grades and particle sizes to suit diverse needs.

- Environmentally Responsible: Supports sustainable and green industrial processes.

-

- High Purity: Available in high-purity grades, ensuring clean and efficient thin-film deposition with minimal contamination.

- Good Electrochemical Properties: MnO₂ thin films are known for their excellent electrochemical behavior, making them ideal for energy storage applications.

- Thermal Stability: MnO₂ exhibits stability at high temperatures, making it suitable for thin-film processes that require heat resistance.

- Wide Range of Applications: The material is versatile, with applications ranging from energy storage and catalysis to optical coatings and sensors.