Showing 13–24 of 39 results

-

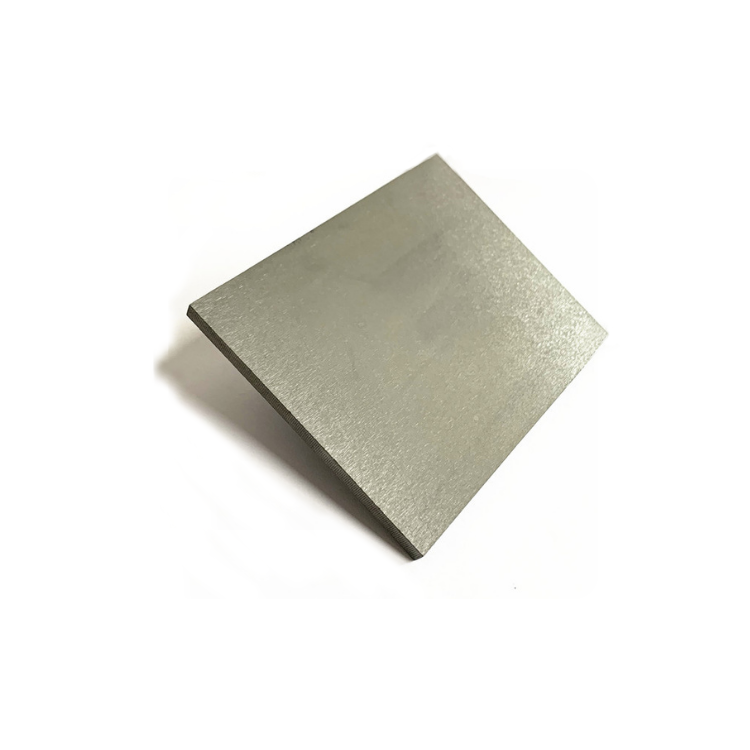

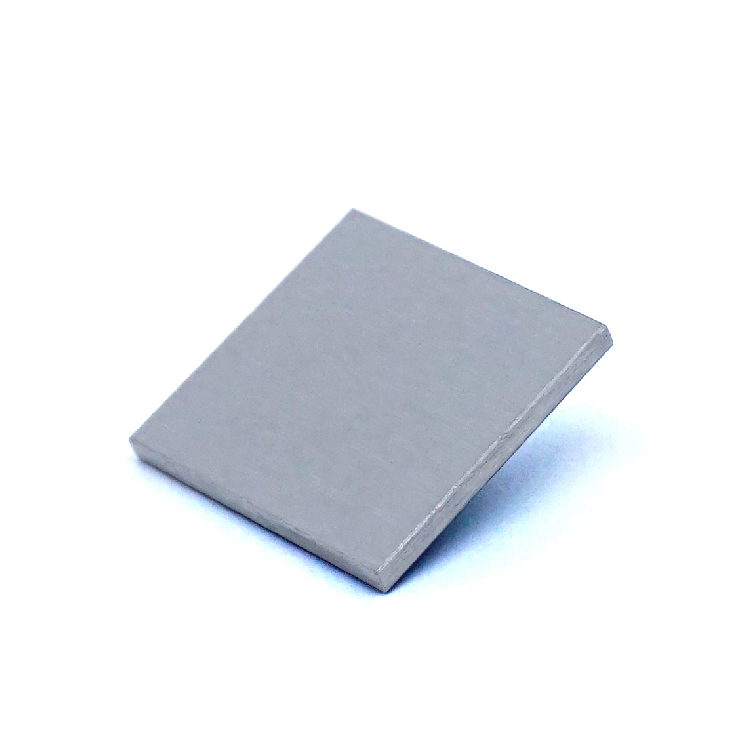

- High Melting Point: Molybdenum has a melting point of 2,623°C, allowing it to withstand extreme temperatures, making it ideal for high-temperature applications.

- Excellent Conductivity: Molybdenum’s electrical and thermal conductivity make it suitable for use in electronics and other heat-sensitive applications.

- Corrosion and Oxidation Resistance: Molybdenum films are highly resistant to corrosion and oxidation, ensuring long-lasting performance in harsh environments.

- Strong Mechanical Properties: Mo provides high tensile strength and stability, making it durable for thin films.

- Adhesion and Uniformity: Molybdenum forms well-adhering and uniform thin films that are highly reflective and durable.

-

- High Purity: ≥99.9% purity, ensuring optimal performance in demanding applications.

- High Temperature Resistance: Molybdenum maintains its strength at elevated temperatures, making it ideal for high-temperature applications.

- Thermal Conductivity: Excellent heat conductivity, ideal for use in applications requiring heat dissipation.

- Corrosion Resistance: Highly resistant to corrosion in harsh environments, such as in the presence of acids and alkalis.

- Fine Powder Form: Available in a wide range of particle sizes, from nano to micron, providing flexibility for various industrial processes.

- Electrical Conductivity: Good electrical conductivity, making it suitable for electronics and electrical applications.

-

Molybdenum sputtering targets play a crucial role in industries that require high-performance, heat-resistant, and conductive coatings. Their application in semiconductors, solar cells, flat panel displays, and aerospace components highlights the versatility and importance of molybdenum in modern technology.

-

- High-Temperature Performance: Its exceptional performance in extreme heat conditions makes molybdenum wire indispensable in industries such as aerospace and electronics.

- Versatility: Molybdenum wire is available in various diameters and lengths, customizable for different industrial needs.

- Durability and Longevity: With its ability to resist wear, oxidation, and deformation, molybdenum wire delivers long-lasting performance.

- Precision Fabrication: It can be produced with tight tolerances and high precision, ensuring reliability in demanding applications.

- Eco-Friendly Material: Molybdenum is a recyclable material, making it an environmentally sustainable choice.

-

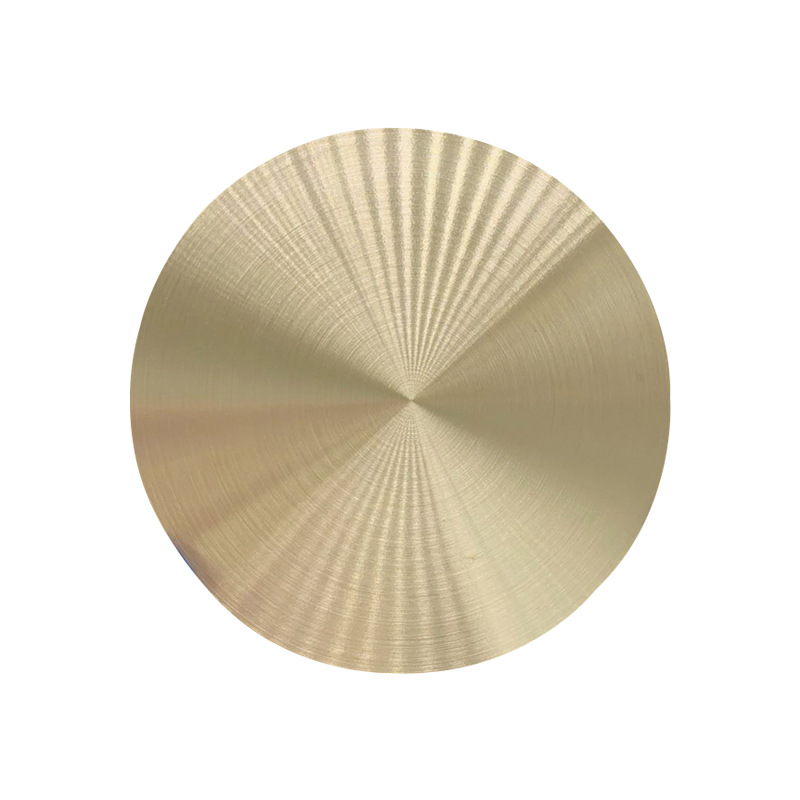

- High purity: Ensures superior film quality with minimal contamination.

- Outstanding hardness: Provides durability for mechanical applications.

- Thermal stability: Ideal for high-temperature environments.

- Customizable dimensions: Available in a variety of sizes, shapes, and thicknesses to meet specific project requirements.

- High deposition efficiency: Optimized for uniform thin-film production.

-

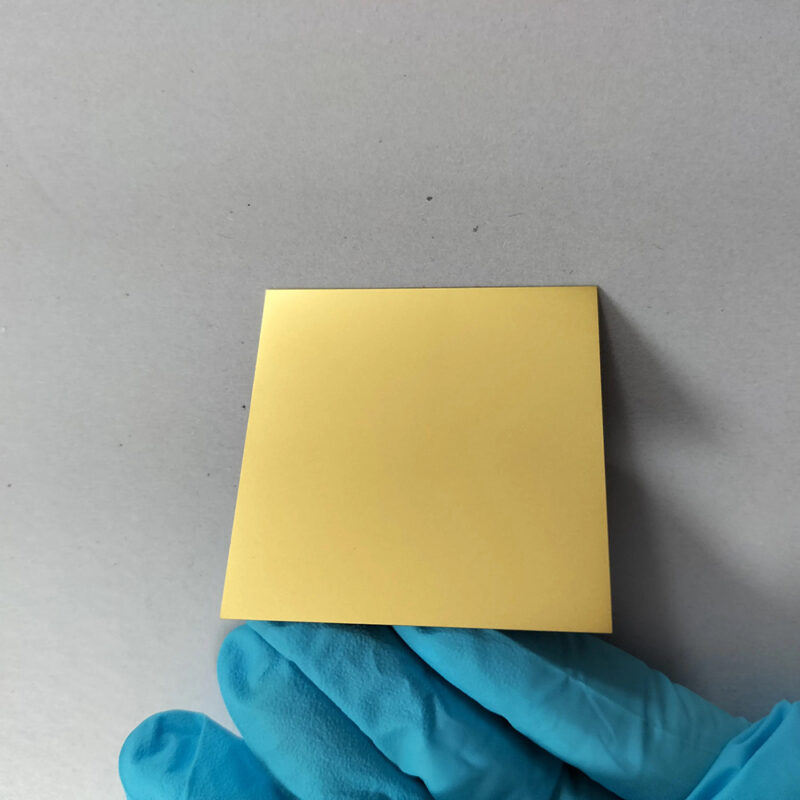

- High Hardness: Provides robust protective coatings for enhanced durability.

- Thermal and Chemical Stability: Ensures excellent performance in harsh environments.

- Electrical Conductivity: Suitable for electronic applications requiring conductive thin films.

- Customizable Options: Available in various dimensions and configurations for specific needs.

- Consistent Quality: Manufactured to deliver uniform deposition rates and film properties.

-

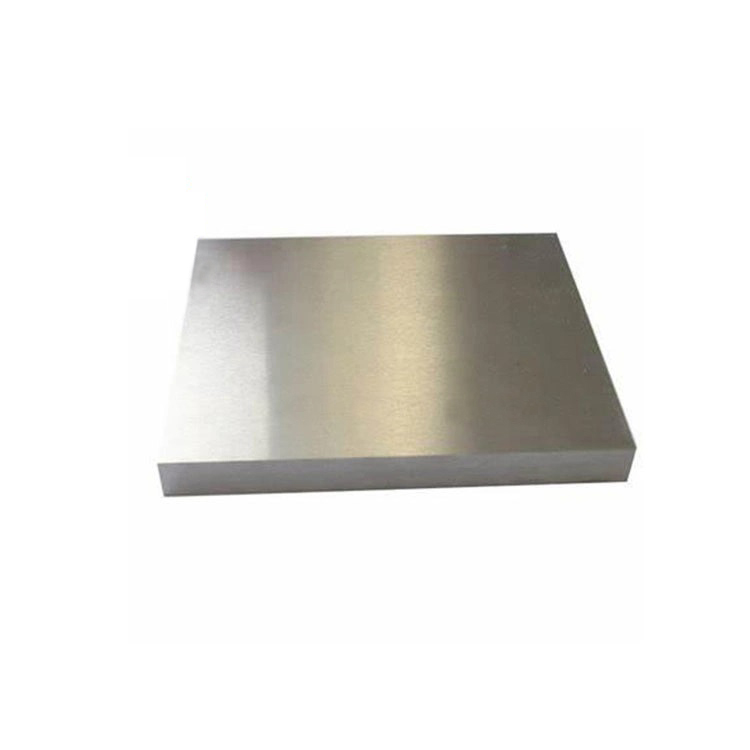

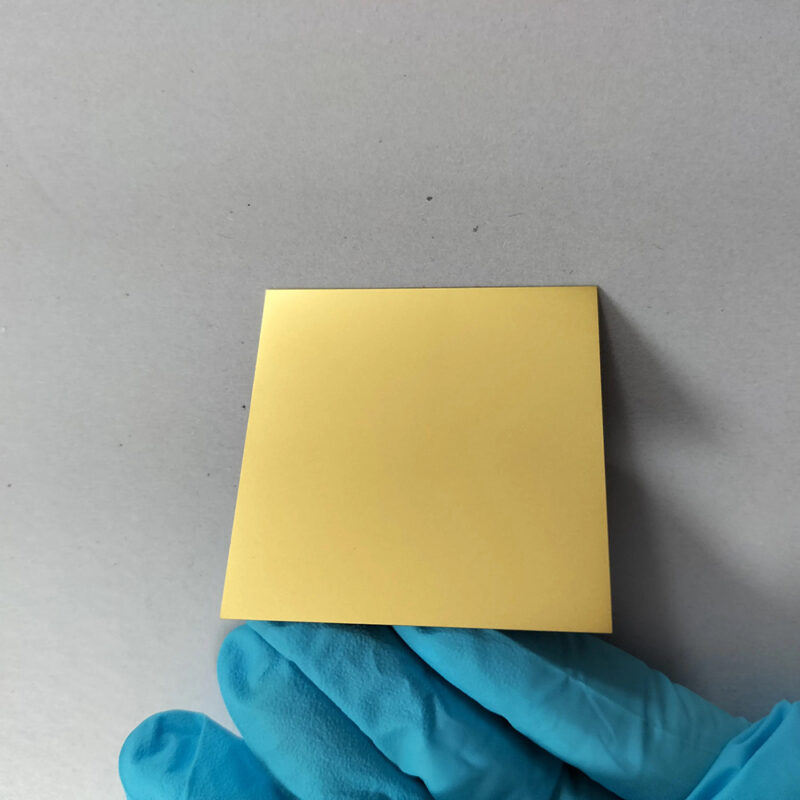

- High Thermal Conductivity: Copper’s excellent thermal conductivity ensures effective heat dissipation in thin-film coatings, crucial for applications in electronics and thermal management systems.

- Mechanical Strength: Molybdenum contributes strength and rigidity to the MoCu alloy, ensuring mechanical stability in high-temperature and high-stress applications.

- Corrosion Resistance: The MoCu alloy provides good resistance to corrosion, making it suitable for use in environments where materials are exposed to moisture, chemicals, or harsh conditions.

- Low Thermal Expansion: The alloy’s combination of molybdenum and copper results in low thermal expansion, reducing the risk of film cracking or damage under thermal stress.

- Customizable Composition: The ratio of molybdenum to copper can be tailored to optimize the thermal, electrical, and mechanical properties to meet specific application requirements.

-

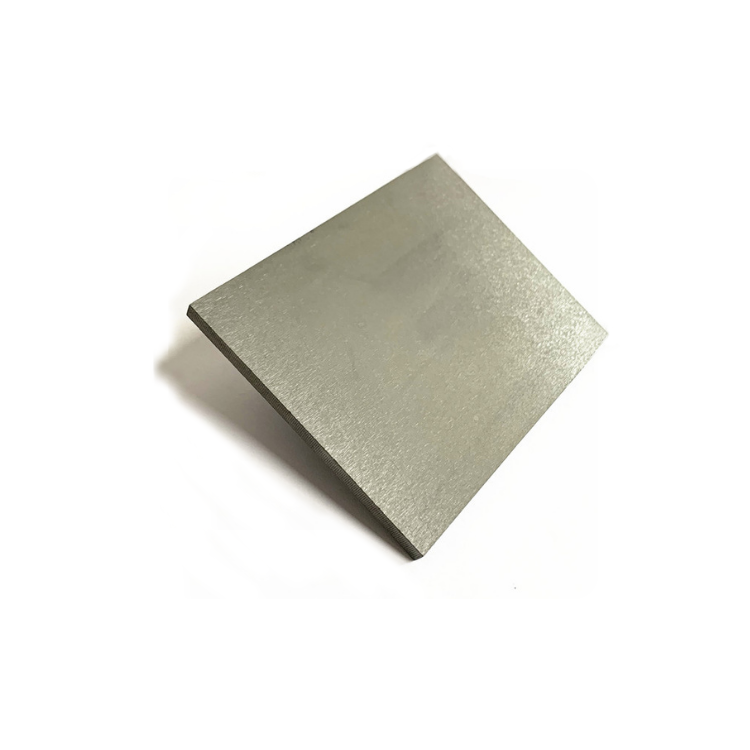

- High Strength: Offers superior mechanical properties, making it suitable for demanding applications.

- Temperature Stability: Maintains integrity at elevated temperatures, which is crucial for aerospace and industrial uses.

- Versatile Composition: Can be tailored to specific ratios of molybdenum and iron for optimized performance.

-

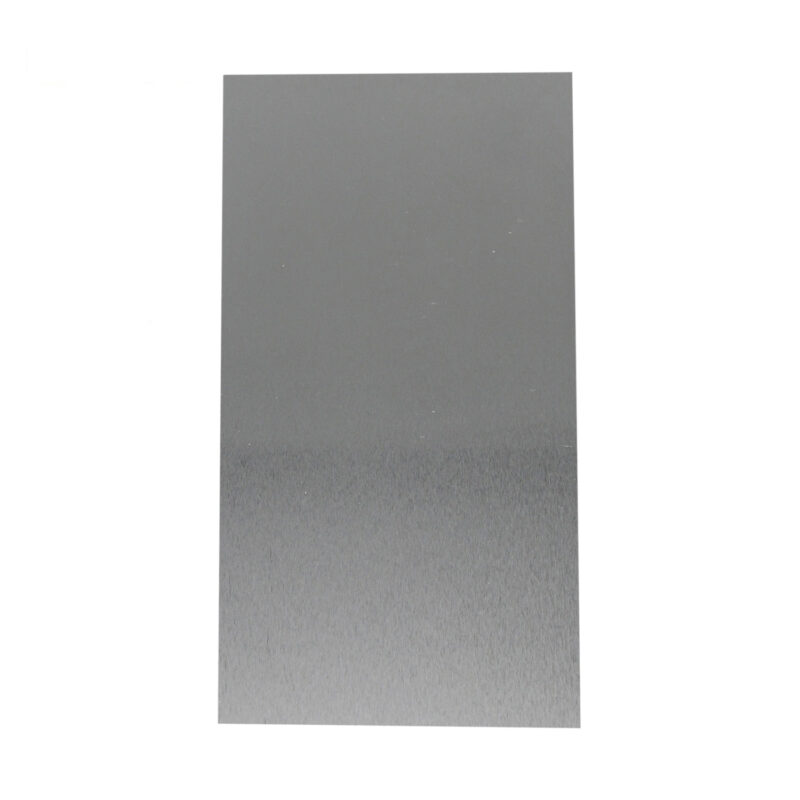

- High Thermal Stability: The MoLa alloy has excellent resistance to deformation and oxidation at high temperatures, ensuring reliability in demanding thermal environments.

- Enhanced Ductility: The addition of lanthanum oxide improves the ductility of molybdenum, making the alloy easier to process and form into thin films without compromising its strength.

- Oxidation Resistance: MoLa exhibits outstanding resistance to oxidation, especially at elevated temperatures, providing long-term stability and durability.

- Improved Machinability: The lanthanum content enhances the machinability of molybdenum, allowing for more precise fabrication of sputtering targets and thin-film coatings.

-

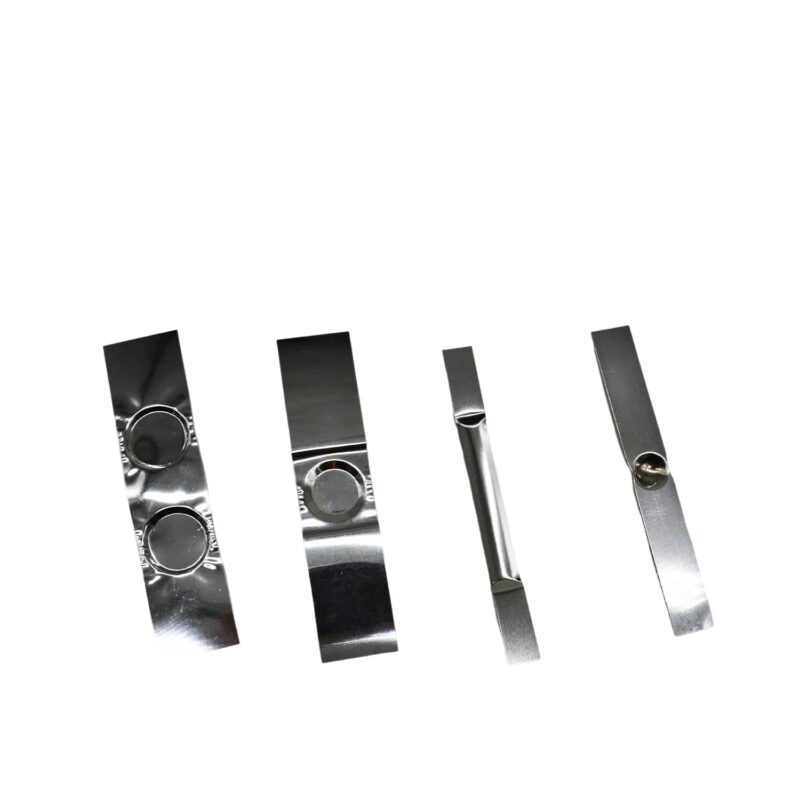

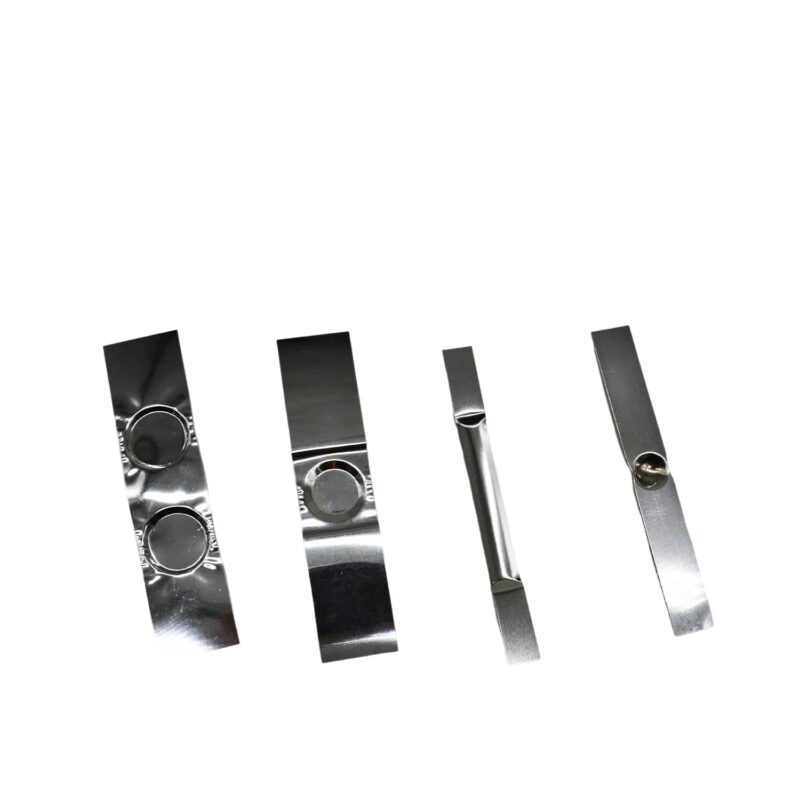

- High Temperature Resistance: Molybdenum boats perform exceptionally well at high temperatures, ensuring stable evaporation even in demanding applications.

- Long Service Life: The durability and thermal stability of molybdenum result in a longer service life, reducing the need for frequent replacements.

- Customization: Molybdenum boats can be customized in terms of shape, size, and material composition to meet specific application requirements.

- Cost-Effective: Compared to other high-performance materials, molybdenum boats offer a balance of affordability and high performance, making them a cost-effective choice for many applications.

-

- High Mechanical Strength: The combination of molybdenum and niobium results in an alloy with high tensile strength, making it suitable for demanding structural applications.

- Thermal Stability: MoNb alloys maintain their mechanical properties at elevated temperatures, making them ideal for high-temperature applications, such as coatings for turbine components.

- Corrosion Resistance: The alloy exhibits excellent resistance to oxidation and corrosion, ensuring long-term performance in harsh environments.

- Low Density: Compared to pure molybdenum, the addition of niobium reduces the density of the alloy, enhancing its performance in weight-sensitive applications.

- Customizable Composition: The molybdenum-to-niobium ratio can be tailored to optimize the properties of the alloy for specific applications, whether enhancing strength, thermal stability, or corrosion resistance.

-

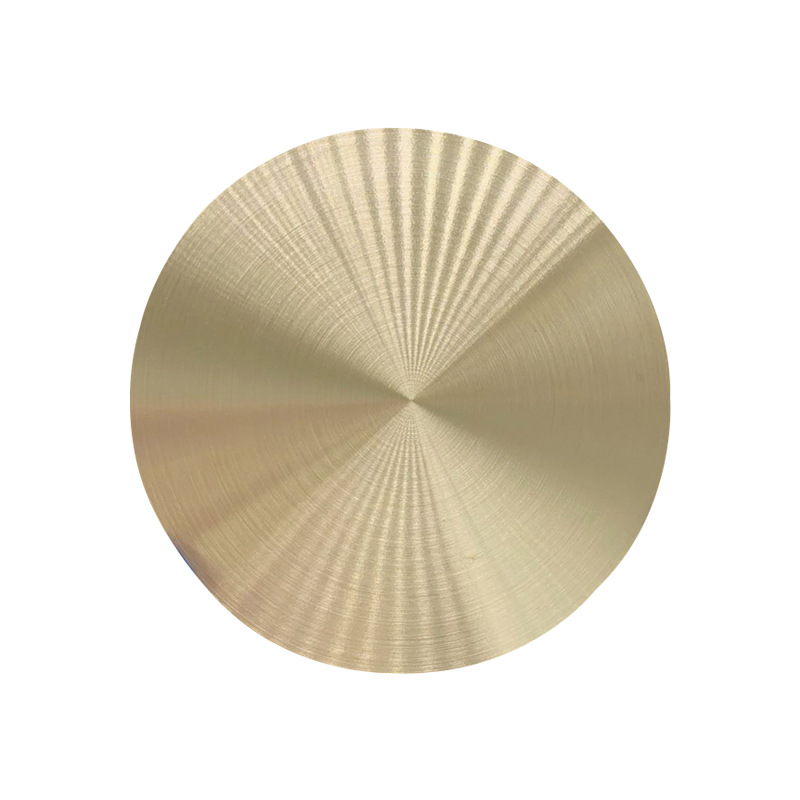

- High Purity: Guarantees superior film quality and reduces impurities.

- Excellent Conductivity: Suitable for applications requiring conductive thin films.

- Thermal Stability: Performs reliably in high-temperature environments.

- Customizable Specifications: Tailored to specific sputtering system requirements.

- Versatility: Compatible with various sputtering techniques, including RF and DC.