Showing 25–36 of 39 results

-

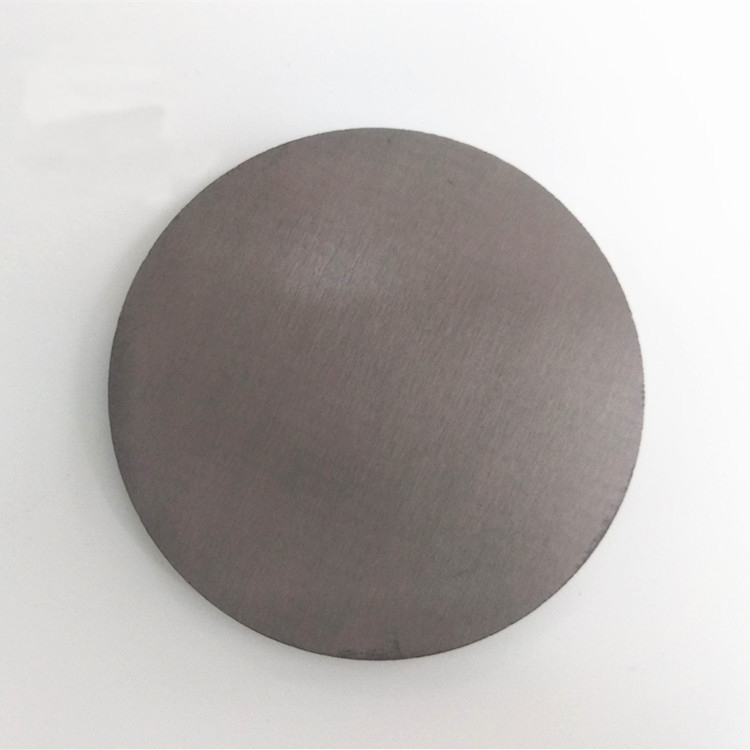

- High Optical Transparency: MoO₃ is transparent in the visible spectrum and is often used in optoelectronic devices that require high transparency and conductivity.

- Excellent Electrical Conductivity: MoO₃ is often used to improve charge injection in electronic devices, particularly in organic electronic applications.

- Thermal Stability: It has a high melting point (~795°C), making it suitable for high-temperature evaporation processes.

- Chemical Properties: MoO₃ is known for its oxidation properties, making it useful in catalysis and other chemical applications.

- Layer Uniformity: When used in deposition processes, MoO₃ can form highly uniform thin films with excellent adhesion properties.

-

- High Purity: Ensures reliable performance in sensitive applications.

- Thermal Stability: Withstands high-temperature environments.

- Oxidizing Agent: Ideal for catalytic and chemical synthesis.

- Semiconducting Properties: Applicable in electronic devices.

- Customizable Particle Sizes: Nano to micrometer scales available.

- Excellent Optical Transparency: Suitable for optical coatings and devices.

-

- High Work Function: MoO₃ is known for its high work function, which makes it ideal for applications requiring efficient charge injection or extraction, such as OLEDs and OPVs.

- Excellent Catalytic Properties: MoO₃ is a robust catalyst, especially in oxidation reactions, making it suitable for industrial chemical processes and catalytic thin films.

- Electrochromic Behavior: MoO₃’s ability to undergo reversible oxidation-reduction reactions makes it ideal for use in electrochromic devices.

- Optical Transparency: MoO₃ thin films can be transparent in the visible and near-infrared regions, which is beneficial for optoelectronic devices requiring transparent electrodes or coatings.

-

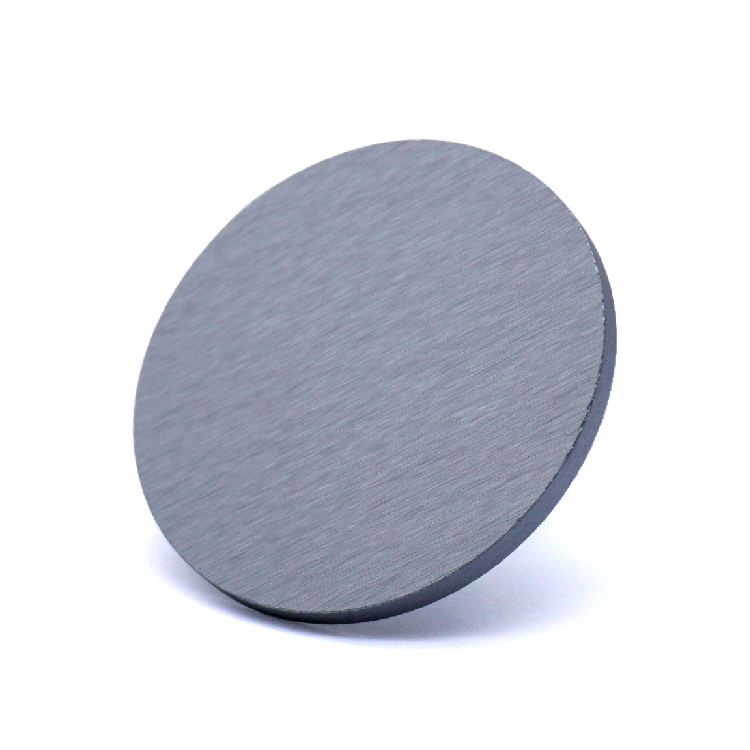

- High Thermal Stability: Performs exceptionally well in extreme temperature environments.

- Enhanced Ductility: Improved mechanical performance over pure molybdenum.

- Excellent Conductivity: Ensures reliable electrical and thermal performance.

- Customizable Options: Tailored to meet the specific requirements of various deposition systems.

- Corrosion Resistance: Long-lasting performance in aggressive environments.

-

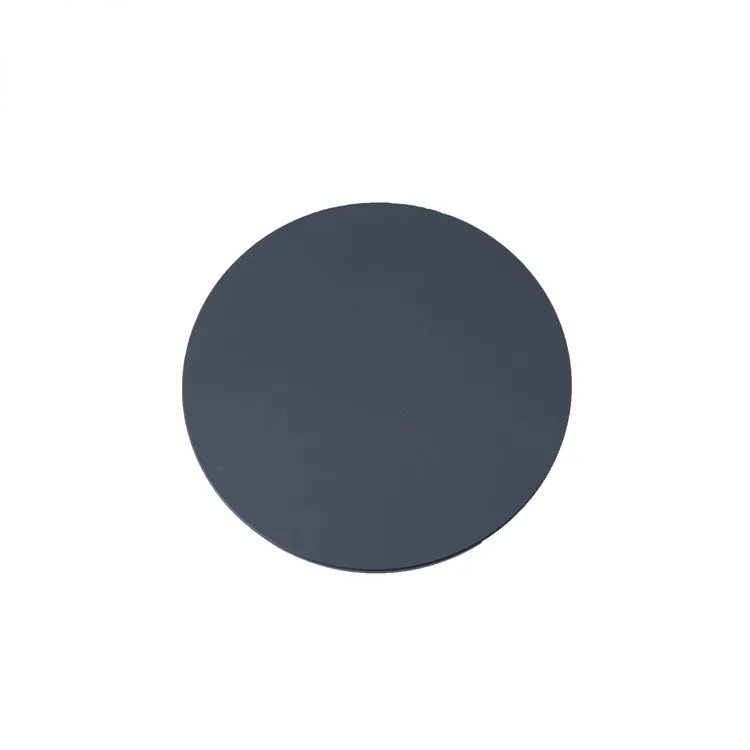

- Layered Structure: MoS₂ has a unique layered structure, allowing for exfoliation into single or few layers, making it ideal for 2D material applications.

- Semiconductor Properties: MoS₂ is a semiconductor with a direct bandgap (~1.8 eV for monolayers), making it suitable for nanoscale transistors and photodetectors.

- Low Friction Coefficient: Its excellent lubrication properties make MoS₂ ideal for coatings that require low friction and high durability, especially in vacuum or extreme conditions.

- Thermal Stability: MoS₂ remains stable at high temperatures, ensuring its effectiveness in harsh environments.

- Corrosion Resistance: MoS₂ provides a protective, corrosion-resistant layer in various applications, extending the life of coated components.

-

- Superior Lubrication: Known for its excellent lubrication properties, particularly in extreme temperature and pressure environments.

- High Wear Resistance: Provides exceptional wear protection and reduces friction in moving parts.

- Thermal Stability: Maintains stability at high temperatures, making it suitable for demanding industrial environments.

- Good Conductivity: Possesses moderate electrical conductivity, making it useful in electrical applications.

- Chemical Resistance: Highly resistant to oxidation and corrosion, making it durable in harsh chemical environments.

- Fine Powder Form: Available in various particle sizes, offering flexibility for different applications.

-

- Layered Structure: MoS2 has a unique layered structure that contributes to its mechanical, electrical, and tribological properties, making it an excellent candidate for advanced coatings and devices.

- Semiconducting Properties: MoS2 is a semiconductor with a direct bandgap in its monolayer form, offering high performance in electronic devices such as transistors and photodetectors.

- Low Friction Coefficient: As a solid lubricant, MoS2 provides a low friction coefficient, making it useful in harsh environments where liquid lubricants are impractical.

- High Thermal and Chemical Stability: MoS2 films exhibit excellent thermal and chemical stability, enabling their use in high-temperature environments and chemically aggressive conditions.

-

- High Purity: Ensures superior thin-film quality and device performance.

- Layered Structure: Facilitates easy exfoliation and 2D material synthesis.

- Stable Chemical Composition: Provides consistent results across various deposition processes.

- Excellent Optical and Electrical Properties: Ideal for advanced electronics and optoelectronics.

- Custom Configurations: Available in tailored sizes, shapes, and thicknesses for specific requirements.

-

- High Melting Point: Excellent stability at temperatures up to 1900°C.

- Superior Oxidation Resistance: Forms a protective silica (SiO₂) layer at high temperatures.

- Good Electrical Conductivity: Suitable for heating element production.

- Corrosion Resistance: Performs well in oxidative and corrosive environments.

- Low Density: Lightweight yet durable for advanced material designs.

-

- Exceptional Thermal Stability: Operates efficiently in high-temperature environments.

- High Purity Levels: Ensures superior film quality with minimal defects.

- Oxidation Resistance: Suitable for protective coatings in harsh conditions.

- Electrical Conductivity: Ideal for use in electronic and semiconductor applications.

- Customizable Options: Targets tailored to specific industrial or research needs.

-

- High Mechanical Strength: The combination of molybdenum and tantalum results in an alloy with excellent tensile strength, making it ideal for demanding structural applications.

- Thermal Stability: MoTa alloys maintain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications, such as coatings for turbine components.

- Oxidation and Corrosion Resistance: The alloy exhibits outstanding resistance to oxidation and corrosion, ensuring long-term performance in harsh environments.

- Customizable Composition: The molybdenum-to-tantalum ratio can be tailored to optimize the properties of the alloy for specific applications, enhancing strength, thermal stability, or corrosion resistance.

-

- Phase Tunability: MoTe₂ can transition between semiconducting and metallic phases, offering versatility in different electronic and optoelectronic applications.

- High Photoresponse: MoTe₂ thin films are highly responsive to light, especially in the infrared spectrum, making them ideal for photodetectors and imaging devices.

- 2D Material Properties: As a layered material, MoTe₂ offers exceptional flexibility and mechanical properties, enabling its use in cutting-edge flexible electronics.

- Thermoelectric Efficiency: MoTe₂ is suitable for thermoelectric applications due to its ability to efficiently convert heat into electricity.