Showing 1–12 of 43 results

-

- High Mechanical Strength: The combination of aluminum, chromium, cobalt, iron, and nickel in the alloy imparts excellent mechanical strength, making it ideal for thin films that require toughness and resistance to mechanical stress.

- Superior Corrosion Resistance: Chromium and nickel contribute to the alloy’s outstanding corrosion resistance, allowing thin films to perform well in corrosive environments, such as in aerospace and marine applications.

- Thermal Stability: AlCrCoFeNi alloy thin films retain their structural properties at elevated temperatures, making them suitable for high-temperature environments, such as in engines and turbines.

- Wear Resistance: Cobalt and chromium enhance the wear resistance of the alloy, making it ideal for hard coatings in industrial tools and machinery parts.

- High-Entropy Alloy Properties: As a high-entropy alloy, AlCrCoFeNi offers a unique combination of properties that cannot be achieved with traditional alloys, including high strength, toughness, and resistance to oxidation and corrosion.

-

- High Strength-to-Weight Ratio: Combines lightweight characteristics with robust mechanical properties.

- Excellent Wear Resistance: Ensures durability in high-stress environments.

- Corrosion and Oxidation Resistance: Performs reliably in extreme chemical or thermal conditions.

- Uniform Microstructure: Enhances performance consistency across applications.

- Wide Applicability: Suitable for 3D printing, surface coatings, and high-performance components.

-

- Corrosion Resistance: Offers good resistance to oxidation and corrosion.

- Enhanced Strength: Combines the lightweight nature of aluminum with the strength of nickel.

- Magnetic Properties: Displays useful magnetic characteristics for specific applications.

-

- Exceptional Corrosion Resistance: Resistant to pitting, crevice corrosion, and stress corrosion cracking in aggressive environments.

- High Strength: Maintains mechanical integrity under high stress and temperature conditions.

- Weldability: Excellent compatibility with various welding methods, including TIG, MIG, and laser welding.

- Versatility: Suitable for additive manufacturing, powder metallurgy, and thermal spray coating applications.

- Thermal Stability: Performs reliably across a wide range of temperatures without compromising material properties.

-

- Excellent Corrosion Resistance: Chromium and nickel provide outstanding corrosion resistance, making CoCrNi thin films suitable for harsh environments, including those found in aerospace, medical, and industrial applications.

- High Mechanical Strength: Cobalt contributes to the alloy’s superior mechanical properties, providing excellent wear resistance and toughness, which are essential for industrial and aerospace components.

- Thermal Stability: The combination of cobalt, chromium, and nickel allows CoCrNi thin films to retain their properties at elevated temperatures, making them ideal for high-temperature environments, such as in aerospace and energy applications.

- Biocompatibility: CoCrNi alloys are biocompatible, making them suitable for use in medical implants and devices, where both mechanical strength and resistance to bodily fluids are required.

- Good Electrical Properties: The electrical conductivity of the alloy makes it suitable for electronic applications, including connectors and semiconductor components.

-

- Corrosion Resistance: The alloy exhibits excellent resistance to oxidation and corrosion, making it suitable for harsh environments.

- Magnetic Properties: Provides good magnetic performance, beneficial for various electromagnetic applications.

- Strength: High mechanical strength enhances durability and performance in demanding applications.

-

- Excellent Electrical and Thermal Conductivity: The copper base ensures superior electrical and thermal conductivity, making it ideal for electronic applications.

- Corrosion Resistance: The addition of nickel and titanium enhances the alloy’s resistance to corrosion, ensuring the longevity of thin films in harsh environments.

- High Strength and Durability: Titanium adds mechanical strength to the alloy, while nickel contributes to its hardness and wear resistance, making it suitable for demanding applications.

- Thermal Stability: CuNiTi alloys maintain their properties at elevated temperatures, making them ideal for high-temperature processes and environments.

- Customizable Properties: The ratio of copper, nickel, and titanium can be adjusted to tailor the alloy’s specific properties for a wide range of applications.

-

- High Entropy Alloy: The near-equal combination of five elements offers unique mechanical and thermal properties, including high strength, excellent wear resistance, and thermal stability.

- Corrosion Resistance: The alloy’s thin films offer exceptional resistance to oxidation and corrosion, even in harsh environments.

- Magnetic Properties: FeCoCrNiMn alloy sputtering targets produce films with strong magnetic properties, ideal for magnetic and electronic devices.

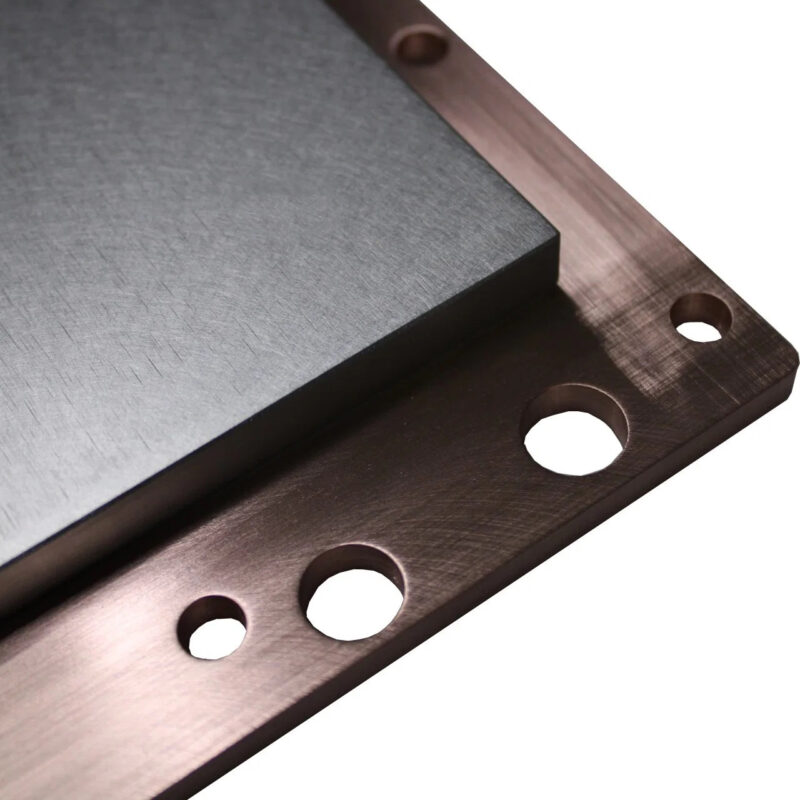

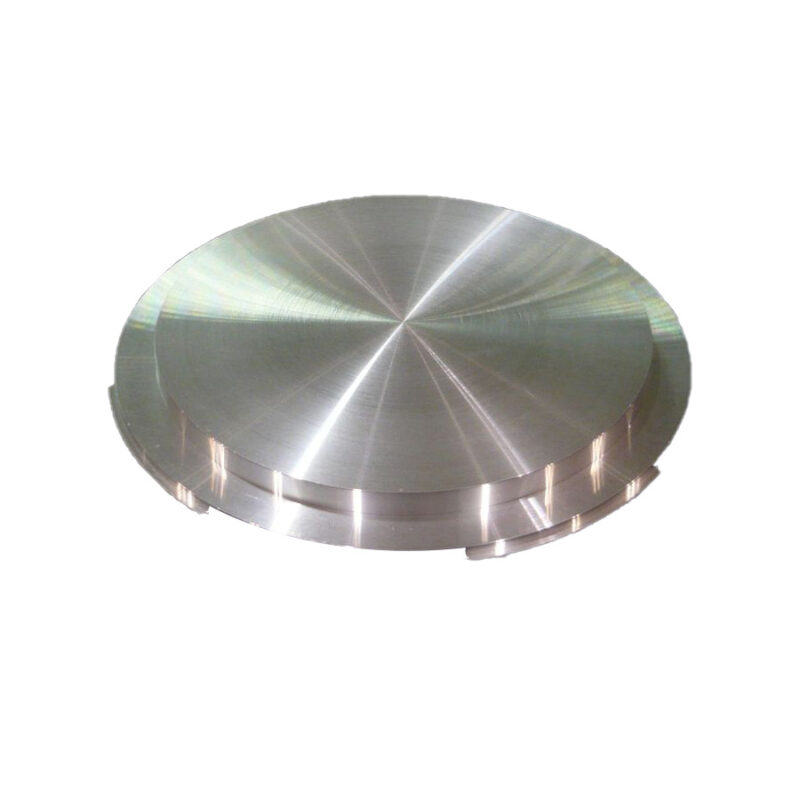

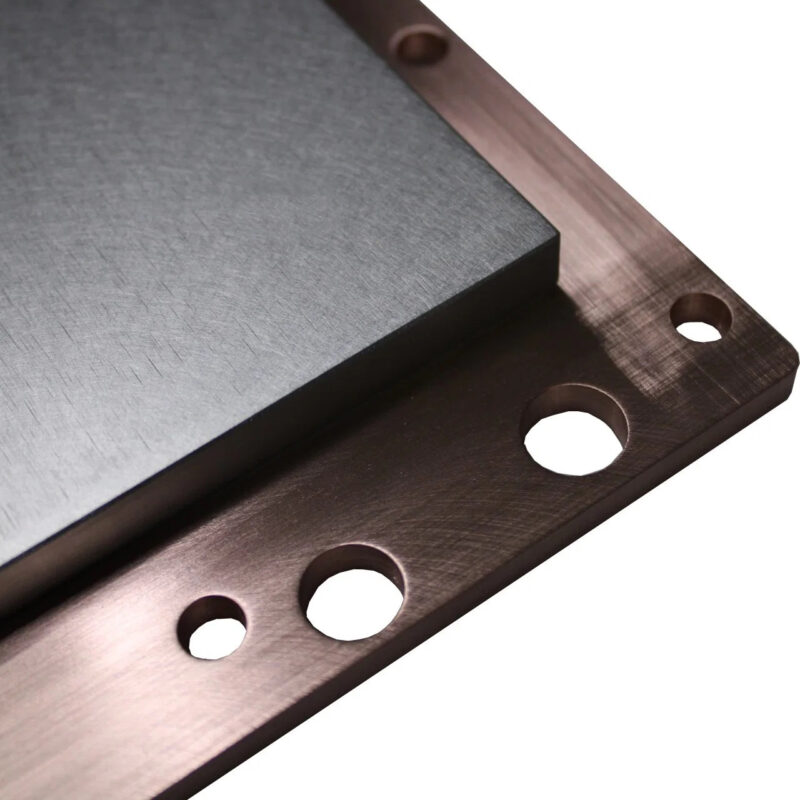

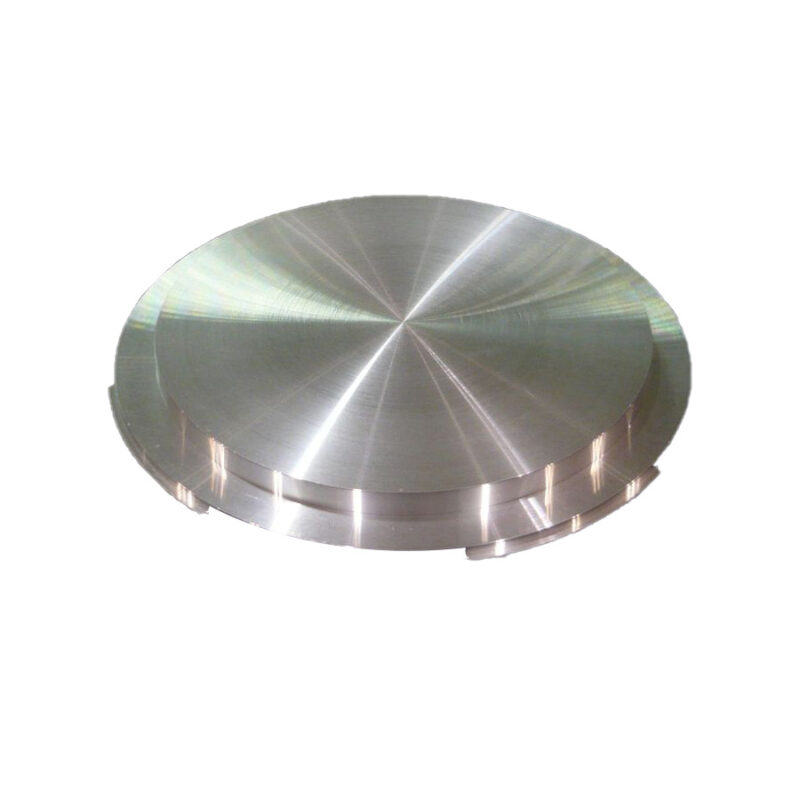

- Customizable Size and Shape: FeCoCrNiMn alloy sputtering targets are available in discs, plates, or custom shapes to meet the requirements of different deposition systems.

-

- Balanced Alloy Composition: Combines Fe, Co, Ni, Al, Cu, and Ti for superior performance.

- High Strength and Durability: Exceptional mechanical properties for demanding environments.

- Thermal Stability: Operates efficiently under extreme temperature conditions.

- Corrosion Resistance: Excellent resistance to oxidation and environmental wear.

- Magnetic Properties: Suitable for applications requiring magnetic performance.

- Customizable Particle Sizes: Available in nano and micro scales for various uses.

-

- Multi-Element Alloy: Balanced composition of Fe, Cu, Al, Cr, and Ni for enhanced properties.

- High Corrosion Resistance: Excellent resistance to oxidation and environmental degradation.

- Superior Mechanical Strength: Outstanding strength and durability for demanding applications.

- Thermal Stability: Maintains performance under high temperatures.

- Customizable Particle Sizes: Tailored for diverse manufacturing needs.

-

- High-Temperature Strength: Maintains excellent mechanical properties at elevated temperatures.

- Oxidation Resistance: Outstanding performance in oxidative environments.

- Thermal Stability: Stable microstructure under cyclic thermal conditions.

- Corrosion Resistance: Effective against chemical and environmental corrosion.

- Process Compatibility: Suitable for 3D printing, thermal spraying, and conventional metallurgy.

-

- High-Temperature Stability: Excellent performance at temperatures up to 900°C, making it suitable for aerospace and industrial applications.

- Corrosion Resistance: Outstanding resistance to oxidation and carburization in high-temperature environments.

- Superior Mechanical Strength: Maintains mechanical integrity under extreme conditions.

- Good Fabricability: Compatible with various manufacturing techniques, including additive manufacturing and welding.

- Versatility: Adaptable to multiple environments, including those with aggressive chemical exposure.