Showing 13–23 of 23 results

-

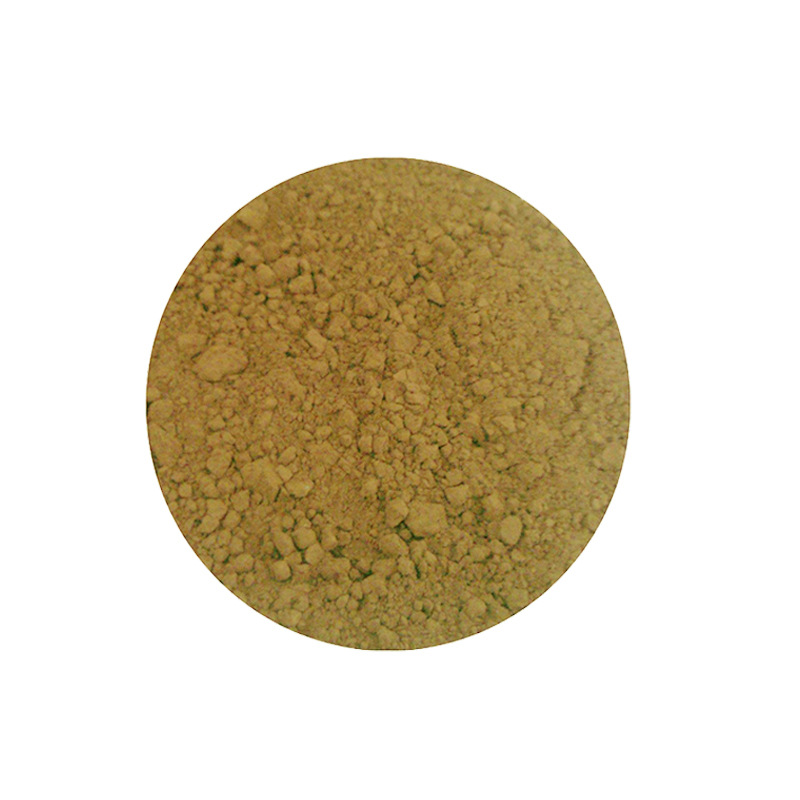

- High Purity: NbN sputtering targets are manufactured with purity levels of up to 99.999%, ensuring excellent film consistency and performance in various deposition applications.

- Electrical Conductivity: Known for its high electrical conductivity, NbN is used in applications requiring efficient electron flow and low resistance.

- Thermal Stability: Niobium nitride exhibits excellent thermal stability, maintaining performance even at elevated temperatures, making it suitable for high-temperature applications.

- Corrosion Resistance: NbN films exhibit outstanding resistance to oxidation and chemical wear, making them ideal for applications in harsh environments.

- Uniformity in Coating: NbN sputtering targets provide excellent film uniformity and density, ensuring reliable coating processes with minimal defects.

- Hardness: The resulting NbN films are known for their exceptional hardness, making them suitable for tough, abrasive conditions.

-

- High purity (≥99.9%).

- Outstanding thermal and mechanical stability.

- Uniform pellet size for precise deposition.

- Customizable sizes and specifications.

- Superior resistance to oxidation, corrosion, and wear.

-

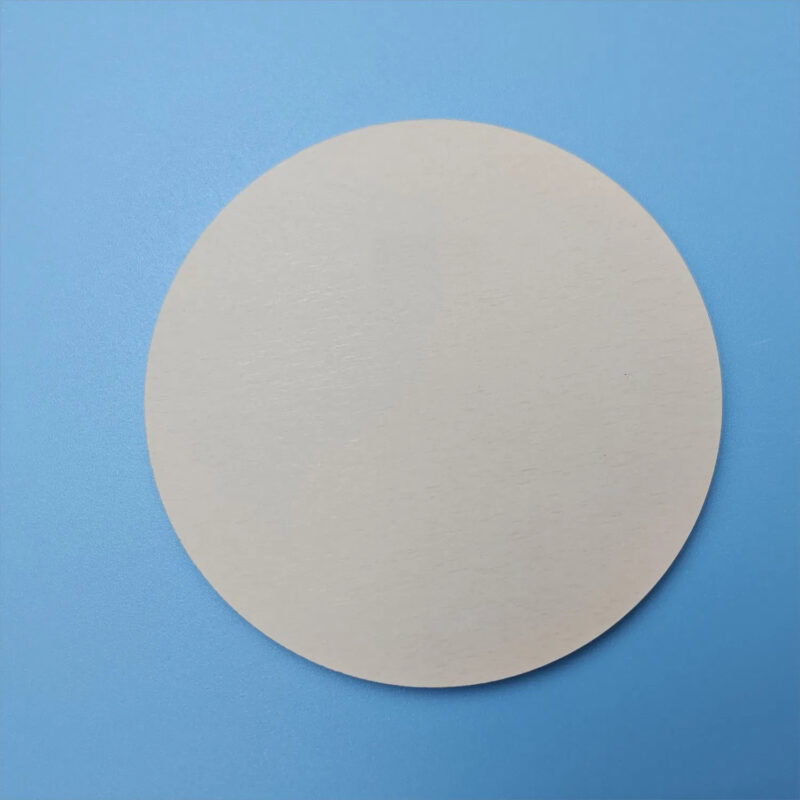

- High Purity: Purity levels up to 99.999% for critical applications.

- Superior Mechanical Strength: Exceptional hardness and fracture toughness.

- Thermal Stability: Outstanding resistance to thermal shock and high-temperature environments.

- Chemical Resistance: Resistant to oxidation, corrosion, and chemical reactions.

- Low Thermal Expansion: Ideal for applications requiring dimensional stability.

- Customizable Particle Sizes: Nano and micron sizes to fit diverse applications.

-

- High Hardness: Si₃N₄ thin films are extremely hard and wear-resistant, making them ideal for applications in harsh mechanical environments.

- Excellent Thermal Stability: Si₃N₄ offers high thermal stability, ensuring reliability and performance in high-temperature applications, such as semiconductors and aerospace components.

- Low Thermal Expansion: Silicon Nitride exhibits low thermal expansion, contributing to its stability and performance under thermal stress.

- Chemical Resistance: Si₃N₄ is chemically inert and resists corrosion from most acids, bases, and chemical agents, which makes it suitable for protective coatings in chemically aggressive environments.

- Insulating Properties: Si₃N₄ films are used as dielectric materials due to their excellent electrical insulating properties, ensuring their use in semiconductor and electronic applications.

-

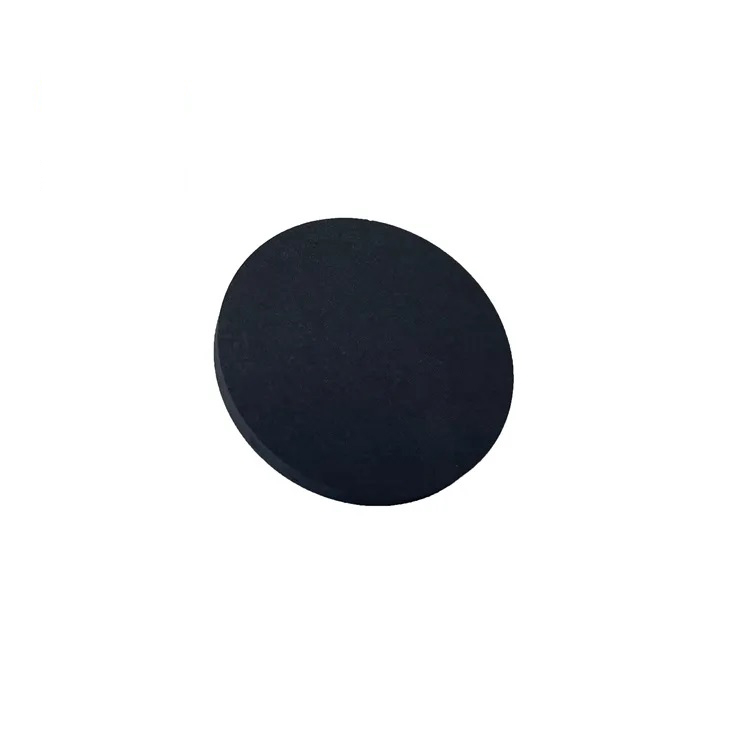

- Excellent Diffusion Barrier: TaN films provide an effective barrier against the diffusion of metals, such as copper, making them crucial for semiconductor devices.

- High Electrical Resistivity: TaN has a relatively high electrical resistivity, which makes it suitable for thin-film resistors and other resistive applications.

- Chemical and Thermal Stability: Tantalum Nitride exhibits excellent stability in extreme chemical and thermal environments, ensuring long-lasting performance in harsh conditions.

- Hardness and Wear Resistance: TaN films offer superior hardness and wear resistance, making them ideal for protective coatings in demanding industrial applications.

- Corrosion Resistance: TaN is resistant to corrosion, making it suitable for use in environments where exposure to chemicals or moisture is a concern.

-

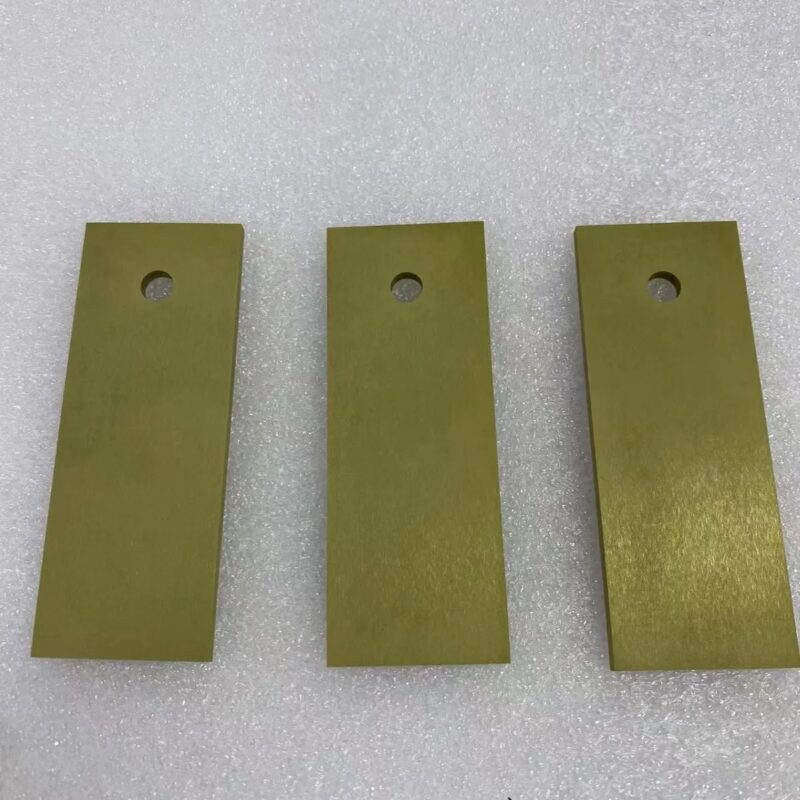

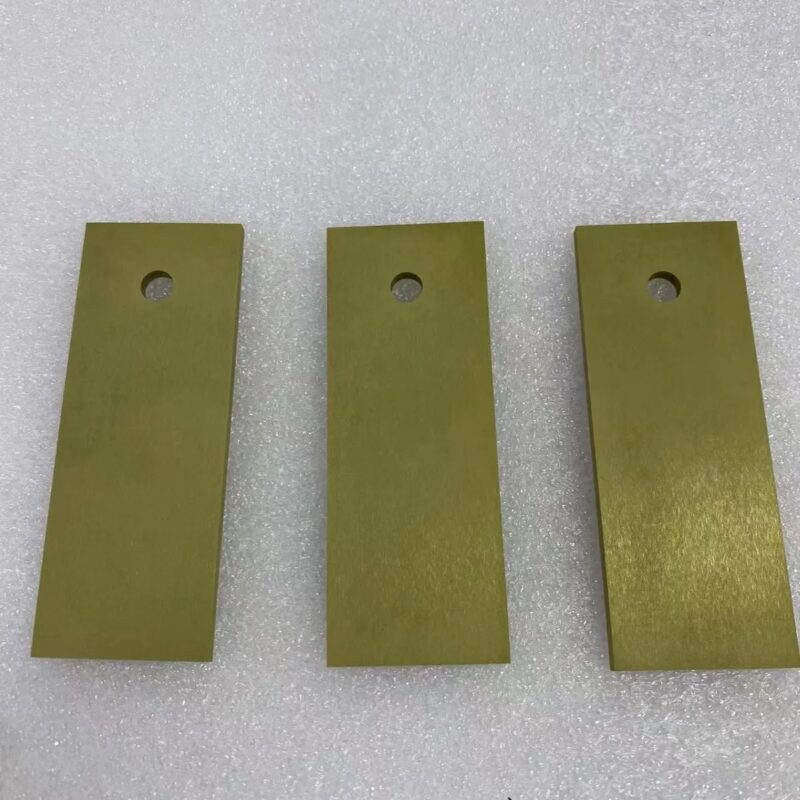

- High Hardness: TiN is extremely hard and resistant to wear, making it ideal for protective coatings in industrial applications.

- Chemical Stability: TiN is chemically inert and resistant to corrosion, which ensures durability in harsh environments.

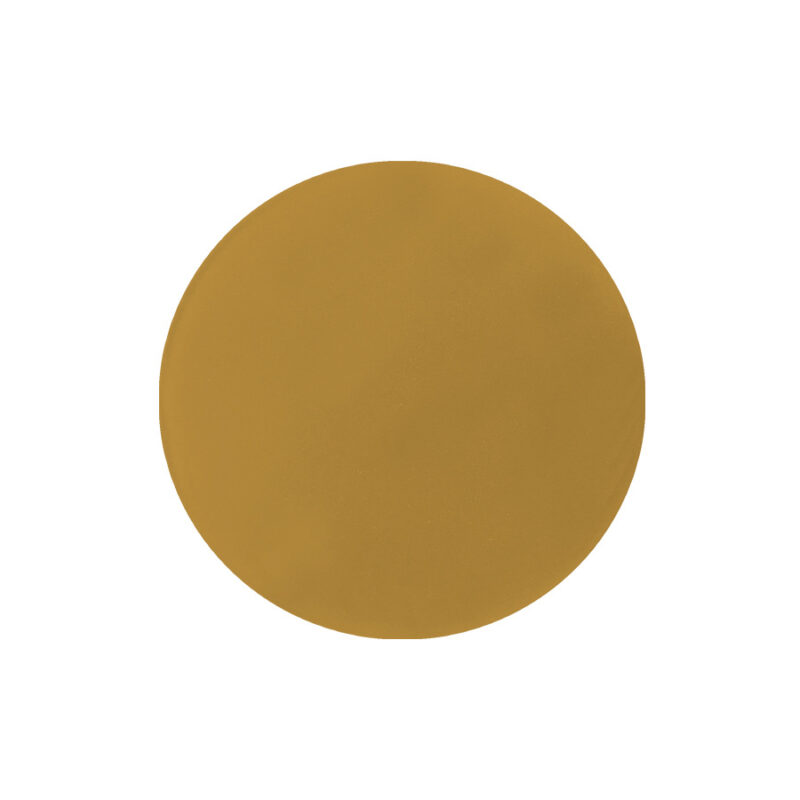

- Golden Appearance: Its distinct golden color makes it a popular choice for decorative coatings.

- High Thermal Conductivity: TiN exhibits good thermal stability, making it suitable for high-temperature applications.

- Electrical Conductivity: TiN thin films are electrically conductive, making them useful in electronic and semiconductor applications.

-

- Hardness: Titanium Nitride has a high hardness level, making it ideal for wear-resistant applications.

- Corrosion Resistance: Exceptional resistance to oxidation and corrosion, extending the lifespan of components.

- High Thermal Stability: TiN maintains its stability even at high temperatures, making it suitable for high-temperature applications.

- Versatility: Can be used as a coating material or as a raw material for composites.

- Biocompatibility: Non-toxic and biocompatible, suitable for certain medical and biomedical applications.

-

- High Hardness: TiN coatings are known for their exceptional hardness, making them ideal for cutting tools and components subject to high friction and stress.

- Corrosion Resistance: TiN provides excellent protection against corrosion and oxidation, extending the lifespan of coated parts and tools.

- High Temperature Stability: TiN remains stable at high temperatures, making it suitable for applications in high-temperature environments such as aerospace or industrial machinery.

- Good Electrical Conductivity: TiN is conductive and is often used in microelectronics as a barrier or adhesion layer in integrated circuits.

- Gold-Like Appearance: TiN has a bright gold color, making it popular for decorative applications and coatings in architectural elements and consumer products.

-

- High hardness and wear resistance, ideal for demanding environments

- Excellent corrosion resistance, prolonging the life of components

- Stable and consistent film quality for precise deposition

- Suitable for high-temperature and high-performance applications

- Enhanced durability in harsh operational conditions

- Compatible with various sputtering systems and deposition techniques

-

- High Hardness and Wear Resistance: ZrN is extremely hard, providing excellent resistance to wear and abrasion, making it ideal for coating cutting tools and other high-wear applications.

- Golden Metallic Appearance: ZrN’s distinct gold color makes it popular for decorative finishes in jewelry and consumer electronics.

- Thermal Stability: ZrN can withstand high temperatures, making it suitable for high-temperature coatings in industrial and aerospace applications.

- Corrosion and Oxidation Resistance: ZrN is highly resistant to corrosion, oxidation, and chemical attack, ensuring long-lasting protection in harsh environments.

- Good Conductivity: ZrN exhibits metallic-like electrical conductivity, making it suitable for electronic applications.

- Low Friction Coating: Provides a low coefficient of friction, reducing wear and improving efficiency in moving parts.

-

- High Hardness: ZrN films exhibit high hardness, making them ideal for protective coatings on cutting tools and wear-resistant applications.

- Corrosion and Oxidation Resistance: ZrN provides excellent resistance to chemical corrosion and oxidation, ensuring longevity and performance in harsh environments.

- Golden Color: ZrN coatings have a gold-like appearance, making them popular for decorative purposes.

- High Thermal Stability: ZrN sputtering targets produce films that can withstand high temperatures, making them suitable for aerospace and semiconductor applications.

- Good Electrical Conductivity: ZrN is electrically conductive, which allows it to be used in some electronic and microelectronic applications.