Showing 25–30 of 30 results

-

- High Purity: Ensures superior film quality and consistent performance.

- Wide Optical Transparency: Suitable for coatings across UV, visible, and IR ranges.

- Stable and Durable: High thermal and chemical stability for demanding processes.

- Customizable Options: Available in various sizes, purities, and configurations.

-

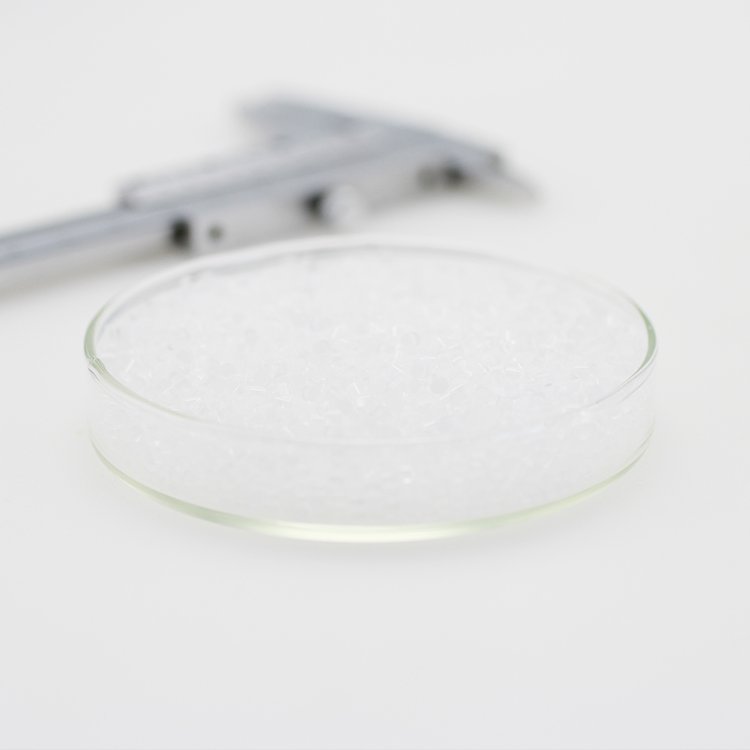

- High Transparency: SiO2 is transparent across a wide spectral range, from UV to IR, making it ideal for optical applications.

- Excellent Insulating Properties: With high dielectric strength and low electrical conductivity, SiO2 is a perfect insulator for microelectronics and semiconductor applications.

- High Melting Point: SiO2 has a melting point of approximately 1,713°C, making it suitable for high-temperature deposition processes.

- Chemical Stability: SiO2 is highly resistant to most acids, bases, and solvents, offering long-lasting protective coatings.

- Mechanical Strength: It provides excellent hardness and durability, ensuring the stability and longevity of thin films.

-

- Excellent Insulator: SiO₂ has a high dielectric strength, making it a perfect insulating material for electronic devices and integrated circuits.

- High Optical Transparency: SiO₂ is highly transparent in the UV, visible, and near-IR regions, making it suitable for optical coatings and protective layers.

- Chemical Stability: SiO₂ exhibits strong chemical resistance, ensuring that deposited films are durable and stable under harsh environmental conditions.

- Thermal Stability: Silicon Dioxide can withstand high temperatures, making it reliable for use in applications that involve thermal stress.

- Hardness: SiO₂ provides a protective layer that is scratch-resistant and durable, making it ideal for surface coatings.

-

- High Electrical Conductivity: Enables efficient current flow in thin films.

- Thermal Stability: Performs well under high-temperature conditions.

- High Purity: Ensures minimal impurities for precise and reliable deposition.

- Versatility: Suitable for a wide range of deposition techniques, including magnetron sputtering.

- Customizable Specifications: Tailored to meet the demands of diverse applications.

-

- Superior Electrical Conductivity: VSi₂ is an excellent conductor of electricity, making it ideal for applications where conductive coatings are required.

- High Thermal Stability: The material maintains its integrity under high temperatures, making it suitable for high-temperature applications.

- Hardness and Durability: Known for its wear resistance, VSi₂ is used in applications that demand exceptional durability and surface hardness.

- Corrosion Resistance: Offers good resistance to corrosion, particularly in aggressive environments.

- Customizable Sizes: Available in various sizes and thicknesses to meet specific application requirements.

-

- Exceptional Thermal Stability: Withstands high-temperature operations.

- High Electrical Conductivity: Ideal for conductive and resistive layers.

- Oxidation Resistance: Reliable performance in harsh environments.

- High Purity: Ensures uniform deposition and minimal contamination.

- Customizability: Available in various dimensions and purities to suit specific needs.