Showing 1–12 of 30 results

-

- Excellent Electrical Conductivity: AlSi alloys offer good electrical conductivity, making them ideal for interconnect layers and conductive films in electronic devices.

- Thermal Stability: AlSi films exhibit high thermal stability, ensuring reliable performance in high-temperature environments, such as semiconductor processing.

- Prevention of Electromigration: The addition of silicon to aluminum helps mitigate electromigration, improving the longevity and reliability of electronic components.

- Corrosion Resistance: AlSi alloys have good resistance to oxidation and corrosion, contributing to the durability of thin films in harsh operating conditions.

- Lightweight and Strong: The lightweight nature of aluminum, combined with the added strength from silicon, makes AlSi alloys versatile in applications requiring both durability and reduced weight.

-

- Enhanced Strength: The addition of silicon increases tensile strength and hardness.

- Good Fluidity: Excellent flow properties make it suitable for casting and evaporation processes.

- Corrosion Resistance: Offers good resistance to oxidation and chemical exposure.

-

- High Strength-to-Weight Ratio: AlSi10Mg powder delivers a high strength-to-weight ratio, making it suitable for lightweight but robust components.

- Excellent Corrosion Resistance: Offers superior resistance to corrosion, ideal for use in harsh environments.

- Good Castability: Provides excellent castability, ensuring high-quality results in additive manufacturing.

- Enhanced Thermal Conductivity: Offers good thermal conductivity, making it ideal for heat-dissipating applications.

- Low Shrinkage: Exhibits minimal shrinkage during the additive manufacturing process, ensuring high precision.

- Ease of Post-Processing: The material can be easily post-processed, including machining, anodizing, and surface treatment.

-

- Electrical Conductivity: The presence of aluminum and copper in the alloy enhances the electrical conductivity of the deposited thin films, making it ideal for semiconductor and electronic applications.

- Thermal Stability: AlSiCu alloy films exhibit excellent thermal performance, ensuring stability in high-temperature environments like semiconductor fabrication and automotive electronics.

- Mechanical Strength: Silicon contributes to the mechanical durability of the alloy, providing resistance to wear and cracking in thin films, which is essential in demanding applications.

- Corrosion Resistance: The alloy offers good resistance to corrosion, ensuring longevity in exposed environments, such as automotive electronics and solar cells.

- Customizable Size and Shape: AlSiCu sputtering targets can be produced in various forms, including discs, plates, and custom shapes, to suit different PVD systems and specific requirements.

-

- Improved Strength: Copper enhances the overall tensile strength and thermal stability.

- Excellent Conductivity: High electrical conductivity makes it suitable for electrical applications.

- Corrosion Resistance: Maintains performance under oxidative conditions.

-

- High Conductivity: CoSi₂ has excellent electrical conductivity, which is crucial for reducing contact resistance in semiconductor applications.

- Strong Silicon Adhesion: It forms stable and well-adhered layers on silicon substrates, ensuring reliable performance in silicon-based devices.

- Thermal Stability: CoSi₂ exhibits high thermal stability, making it suitable for high-temperature processing and applications.

- Corrosion Resistance: The material shows good resistance to oxidation and other forms of corrosion, increasing the longevity of electronic components.

- Low Resistance: CoSi₂ reduces the contact resistance between metal layers and silicon, improving the overall efficiency of electronic devices.

-

- High Purity: Ensures the production of defect-free thin films with superior properties.

- Thermal Stability: Withstands high-temperature processes without degradation.

- Excellent Conductivity: Suitable for electronic and optoelectronic applications.

- Customizable Design: Available in a variety of shapes and sizes to fit specific sputtering systems.

- Durable Material: Resistant to oxidation and corrosion for reliable long-term use.

-

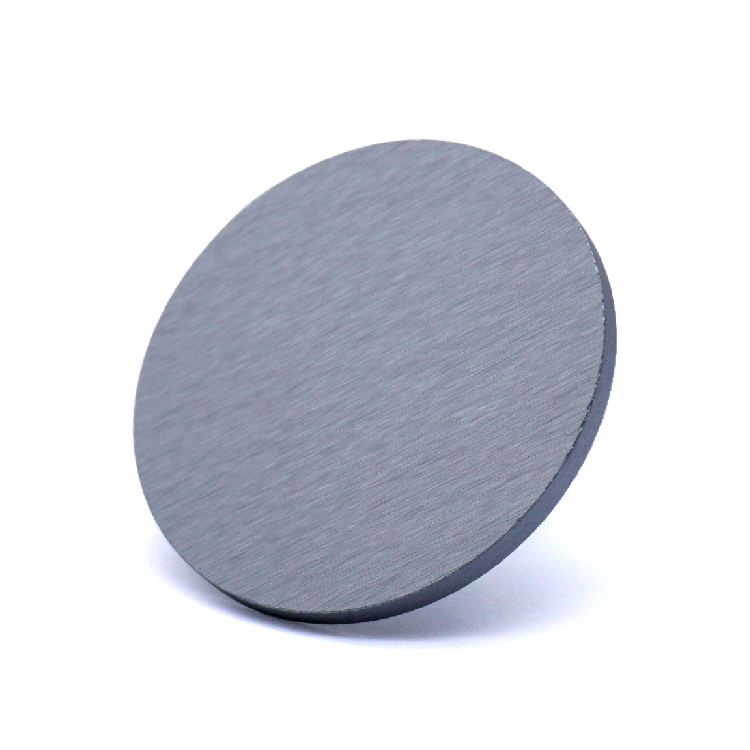

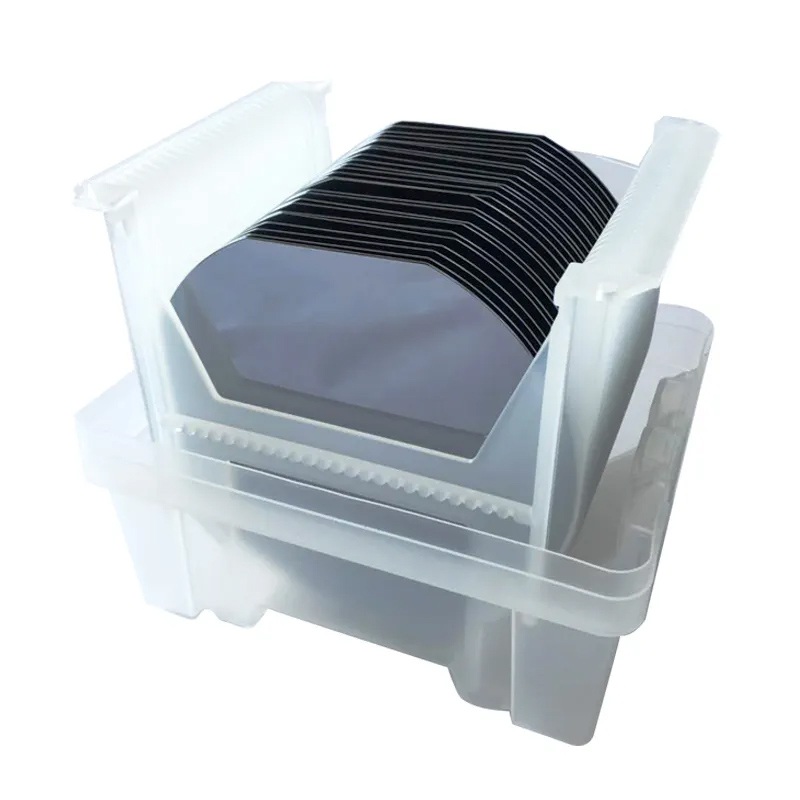

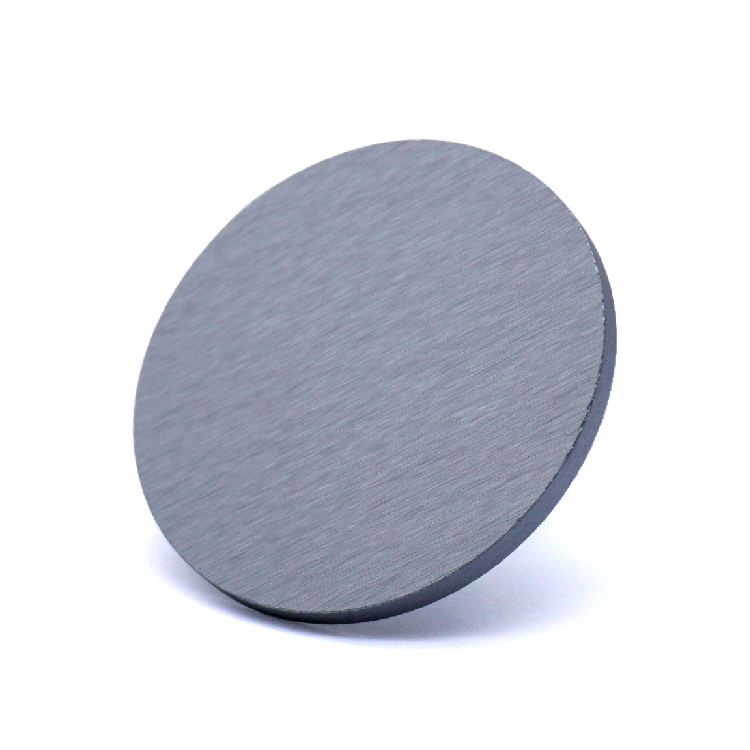

- Diameter Choices: 2″ to 12″ (or custom sizes).

- Doping Concentration: Custom doping profiles for N-type and P-type wafers.

- Thickness Variability: From ultra-thin wafers to thick substrates.

- Crystal Orientation: Standard orientations include <100>, <111>, <110>, with custom orientations available.

- Flat & Edge Treatment: Rounded, chamfered, or custom edge profiles.

- Surface Finishing:

- SSP (Single-Side Polished) or DSP (Double-Side Polished).

- Oxide coating, etched surfaces, or epitaxial layers upon request.

-

- High Melting Point: Excellent stability at temperatures up to 1900°C.

- Superior Oxidation Resistance: Forms a protective silica (SiO₂) layer at high temperatures.

- Good Electrical Conductivity: Suitable for heating element production.

- Corrosion Resistance: Performs well in oxidative and corrosive environments.

- Low Density: Lightweight yet durable for advanced material designs.

-

- Exceptional Thermal Stability: Operates efficiently in high-temperature environments.

- High Purity Levels: Ensures superior film quality with minimal defects.

- Oxidation Resistance: Suitable for protective coatings in harsh conditions.

- Electrical Conductivity: Ideal for use in electronic and semiconductor applications.

- Customizable Options: Targets tailored to specific industrial or research needs.

-

- High Thermal Stability: Performs reliably in extreme temperatures.

- Oxidation Resistance: Ideal for protective coatings in harsh environments.

- Superior Mechanical Strength: Enhances the durability of deposited films.

- High Purity Standards: Ensures film quality and minimal contamination.

- Custom Solutions Available: Adaptable to meet specific industrial or research requirements.

-

- High Electrical Resistivity: The NiCrSi alloy has a stable electrical resistivity, making it ideal for thin-film resistor applications and other electronics requiring consistent electrical performance.

- Corrosion and Oxidation Resistance: The combination of nickel and chromium provides excellent resistance to corrosion and oxidation, even at elevated temperatures.

- Thermal Stability: The NiCrSi alloy retains its mechanical and electrical properties at high temperatures, ensuring reliable performance in thermal management systems and high-temperature applications.

- Customizable Composition: The nickel, chromium, and silicon content can be adjusted to fine-tune the properties of the alloy for specific applications, including optimizing resistivity or corrosion resistance.