-

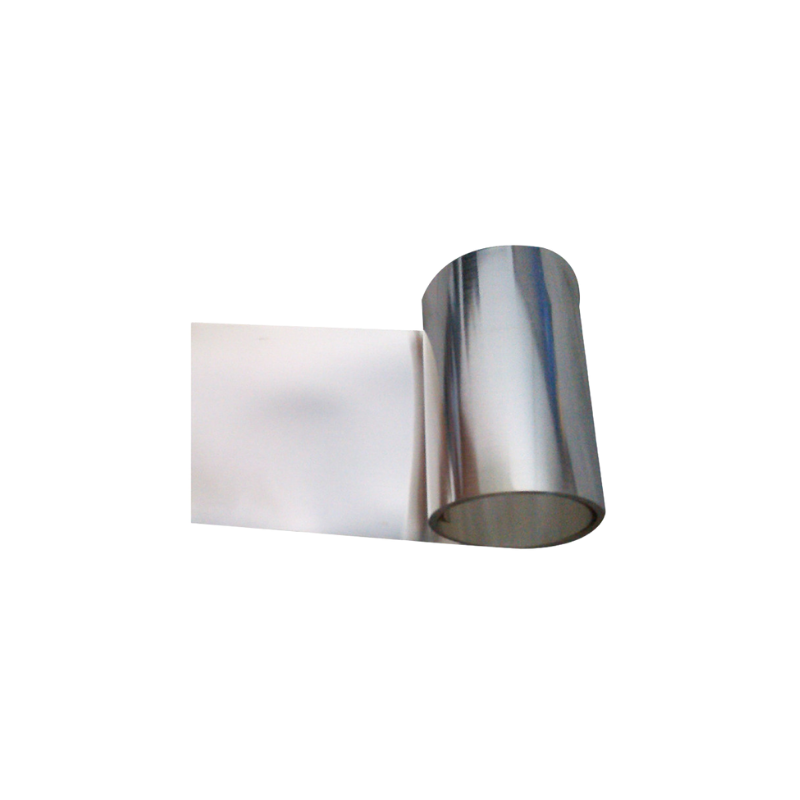

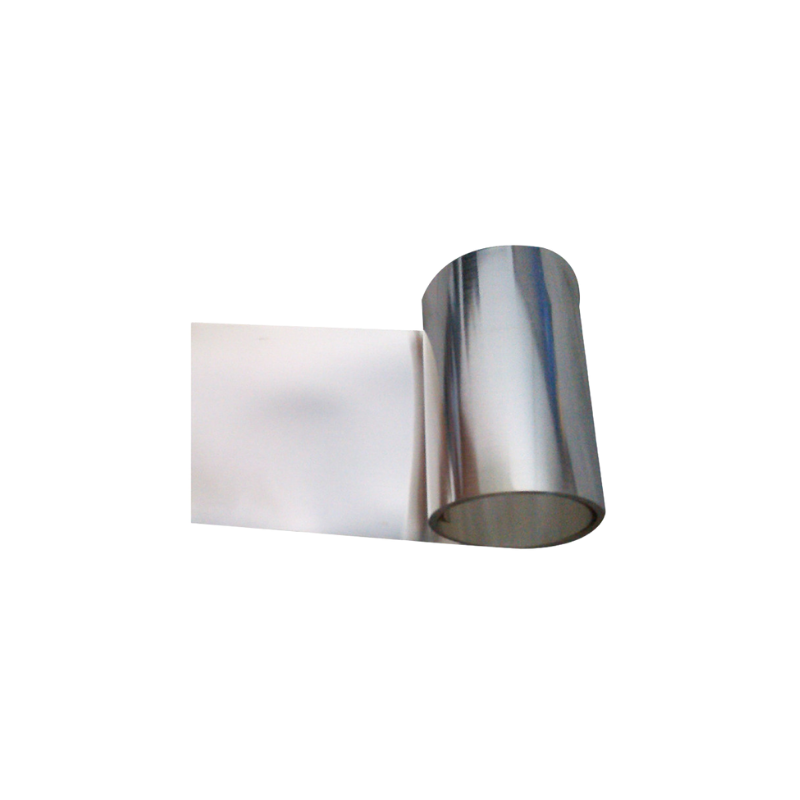

- High Electrical Conductivity: Silver foil is renowned for its superior electrical conductivity, making it essential for electronic components such as circuits and connectors.

- Excellent Thermal Conductivity: Silver has excellent thermal conductivity, allowing it to efficiently transfer heat, making it useful in applications that require heat dissipation.

- Corrosion Resistance: Silver foil is resistant to oxidation and corrosion, which ensures its longevity even in harsh environments.

- Malleability and Ductility: Silver foil is highly malleable, which allows it to be easily shaped into thin sheets or forms without breaking. This malleability adds to its versatility in various applications.

- Reflective Surface: Silver foil has a high reflective surface, which makes it ideal for use in optics and reflective coatings.

- Non-Toxic and Safe: Silver foil is non-toxic and safe for use in a wide range of applications, including food packaging and medical devices.

-

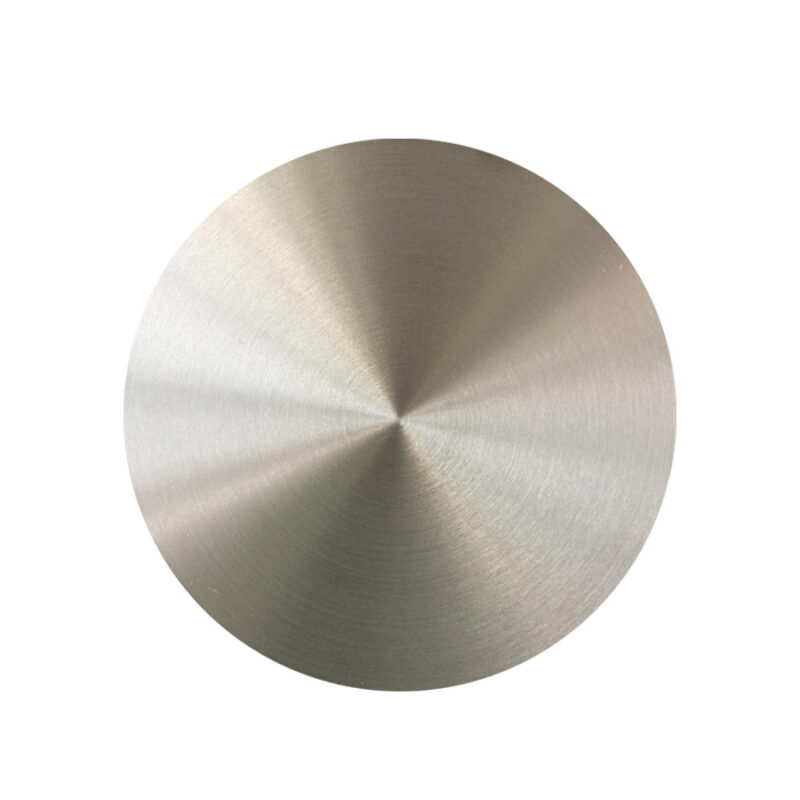

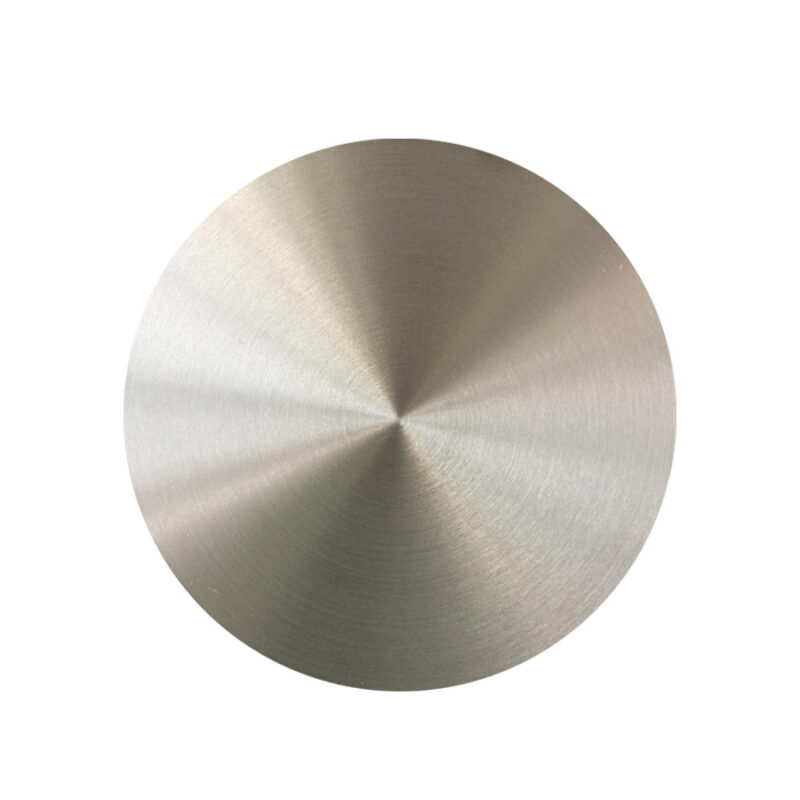

- High Purity: Available in 99.99% (4N) or higher purity to produce clean and contamination-free silver thin films, especially crucial in semiconductor and medical applications.

- Exceptional Reflectivity: Silver’s high reflectivity in the visible and infrared spectrum makes it ideal for optical applications and energy-efficient coatings.

- Excellent Electrical Conductivity: Silver is the most conductive of all metals, ensuring optimal performance in electronic and photovoltaic applications.

- Corrosion Resistance: Thin silver films provide a protective layer that resists tarnishing and corrosion, maintaining performance over time.

- Uniform Deposition: Ag pellets ensure even and consistent evaporation for creating uniform thin films in both thermal and electron beam evaporation systems.

- Antibacterial Properties: Silver’s natural ability to inhibit bacterial growth makes it suitable for medical applications and sterile environments.

-

- Superior Electrical Conductivity: The best among metals, making it ideal for electronic components.

- High Thermal Conductivity: Efficient in heat transfer applications.

- Antimicrobial Properties: Silver ions disrupt bacterial cell walls, making it useful in medical applications.

- Reflectivity: Silver is highly reflective, making it suitable for mirrors and coatings.

-

Silver (Ag) sputtering targets are used in physical vapor deposition (PVD) processes to deposit thin films of silver onto various substrates. Silver is renowned for its outstanding electrical conductivity, reflectivity, and antimicrobial properties, making it a popular choice in a wide range of industries, including electronics, optics, and healthcare.

-

- High purity (≥99.99%).

- Exceptional infrared transmission properties.

- Semiconductor material with high thermal and chemical stability.

- Suitable for thin-film deposition techniques like PVD and CVD.

- Custom sizes and shapes available.

-

- High purity (≥99.9%).

- Excellent thermoelectric and optical properties.

- Stable in various thin-film deposition techniques.

- Uniform size for consistent vaporization and deposition.

- Custom pellet sizes and compositions available.

-

- High Electrical Conductivity: Excellent conductive properties due to the high silver content.

- Lightweight and Strong: Combines the strength of aluminum with the conductivity of silver, providing durable yet lightweight solutions.

- Corrosion Resistance: Superior resistance to corrosion and oxidation, ensuring longevity in demanding environments.

- Thermal Conductivity: Offers efficient heat transfer for various thermal management applications.

- Customizable Sizes: Available in a range of particle sizes to meet specific application requirements.

-

- Superior Electrical Conductivity: Silver provides excellent electrical conductivity, making AgCr thin films ideal for use in electronic applications requiring efficient conduction of electricity.

- Corrosion Resistance: Chromium enhances the corrosion resistance of AgCr alloy, allowing the thin films to perform reliably in environments prone to oxidation and chemical exposure.

- Durability and Wear Resistance: The addition of chromium improves the mechanical strength and wear resistance of AgCr thin films, ensuring longer-lasting performance in various industrial applications.

- High Reflectivity: Silver’s reflective properties make AgCr thin films suitable for optical coatings where high reflectivity is desired, such as in mirrors and optical components.

- Customizable Composition: The ratio of silver to chromium in the alloy can be adjusted to tailor the properties of the thin film for specific applications, such as improving conductivity or enhancing corrosion resistance.

-

- High Electrical Conductivity: Offers excellent conductivity, making it ideal for electronic applications.

- Enhanced Strength: The copper content enhances the mechanical strength compared to pure silver.

- Corrosion Resistance: Provides good resistance to oxidation, extending the lifespan of components.