Showing 13–24 of 25 results

-

- High Thermoelectric Efficiency: Exceptional figure of merit (ZT) for energy conversion.

- Excellent Electrical Properties: High electrical conductivity suitable for semiconducting applications.

- Thermal Stability: Retains performance under varying temperature conditions.

- Customizable Options: Adjustable particle sizes and purity levels to meet specific needs.

- Versatile Applications: Ideal for thermoelectric modules, IR detectors, and advanced coatings.

- Eco-Friendly Alternative: Reduces reliance on less sustainable materials in energy applications.

-

- High Thermoelectric Efficiency: Sb₂Te₃ exhibits excellent thermoelectric performance with a high figure of merit (ZT) near room temperature, making it one of the most effective materials for energy conversion and cooling applications.

- Phase-Change Properties: Its ability to rapidly switch between different phases with thermal cycling makes Sb₂Te₃ ideal for memory devices such as phase-change random-access memory (PCRAM).

- Topological Insulator Properties: Sb₂Te₃ is used in cutting-edge research into topological insulators, with potential applications in quantum computing and advanced electronics.

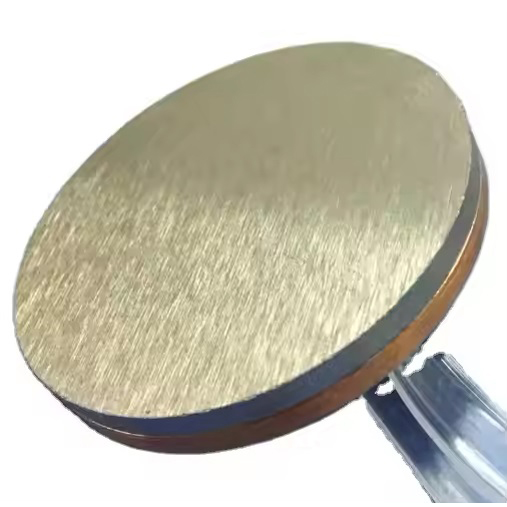

- Customizable Thin Films: Sputtering targets allow for controlled deposition of Sb₂Te₃ films with tailored thickness, composition, and properties for specific device requirements.

-

- High Purity: Ensures minimal contamination and consistent deposition performance.

- Optimal Stoichiometry: Precisely controlled Si and Te ratio for superior material properties.

- Wide Compatibility: Suitable for various deposition techniques, including PVD and sputtering.

- Excellent Film Properties: Supports the production of uniform, high-quality thin films.

- Customizable Options: Flexible sizes and shapes to fit diverse sputtering systems.

-

- Thermoelectric Efficiency: Outstanding thermoelectric performance with a high Seebeck coefficient and low thermal conductivity.

- Optoelectronic Properties: High carrier mobility and sensitivity to infrared light.

- Customizable Sizes: Tailored particle sizes for various research and industrial needs.

- Stable Crystal Structure: Rock-salt (NaCl-type) structure for robust stability.

- High Purity: Ultra-pure material for precise and repeatable results.

-

- High Thermoelectric Efficiency: SnTe exhibits outstanding thermoelectric properties, making it ideal for both thermoelectric generation and cooling applications.

- High Purity: ≥99.9% purity available, ensuring high-quality performance and minimal contamination in applications.

- Stable Performance: Maintains high performance under both high and low-temperature conditions.

- Customizable Particle Size: Available in various particle sizes ranging from nanometers to micrometers, tailored to specific application needs.

- Environmentally Safe: Non-toxic material suitable for green and sustainable energy applications.

- Versatile Applications: Can be used in both thermoelectric generators and thermoelectric coolers, along with other energy conversion and cooling systems.

-

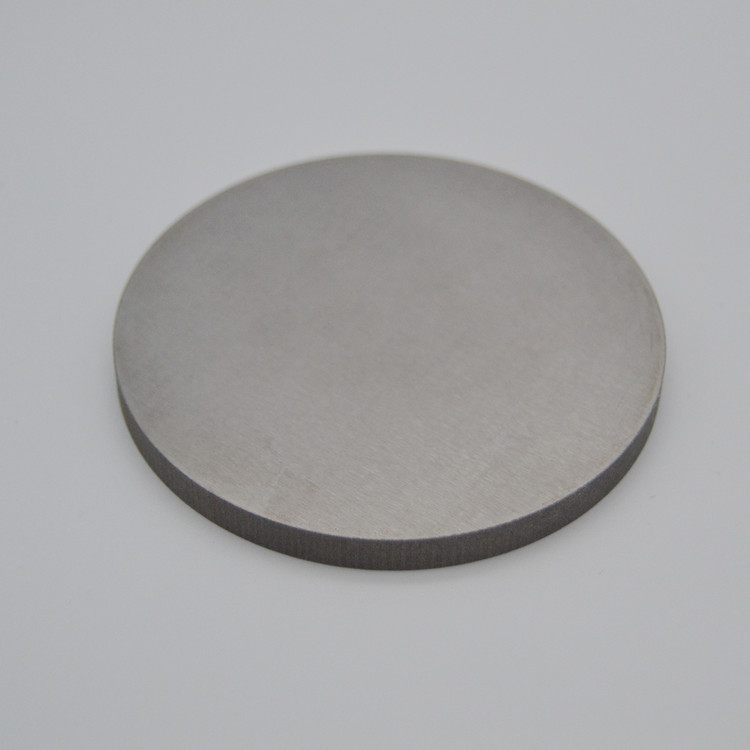

- High Purity: Reduces impurities, ensuring superior thin-film quality.

- Stable Composition: Precisely controlled Sn and Te ratio for consistent performance.

- Excellent Film Properties: Produces smooth, high-density, and defect-free films.

- Versatile Deposition: Suitable for PVD and other thin-film coating techniques.

- Customizable Options: Flexible sizes and specifications to fit diverse sputtering systems.

-

- High Thermoelectric Efficiency: Tellurium-based materials, like Bi2Te3, are widely recognized for their superior thermoelectric performance, essential for thermoelectric cooling and power generation.

- Infrared Transparency: Tellurium compounds exhibit transparency in the infrared spectrum, which makes them useful for IR optics and imaging devices.

- Phase-Change Properties: Tellurium has excellent phase-change properties, which enable its application in PCM for non-volatile memory storage.

- High Purity: Tellurium used in evaporation is typically of high purity (≥ 99.9%), ensuring uniformity and high-quality thin film deposition.

- Stable Evaporation: Tellurium can be evaporated with thermal and electron-beam techniques, providing consistent deposition rates for thin films.

-

- Semiconductor Properties: Tellurium’s ability to act as a semiconductor makes it crucial in electronics, especially in combination with other elements like cadmium and bismuth.

- Thermoelectric Efficiency: Tellurium’s thermoelectric properties allow it to convert heat energy into electrical energy, making it valuable for energy-harvesting applications.

- Corrosion Resistance: When alloyed with metals like copper and steel, tellurium improves corrosion resistance and machinability.

- High Density: Tellurium has a high density, making it suitable for certain high-performance alloys and specialized applications in material science.

-

- Excellent Photovoltaic Properties: TeCd, especially CdTe, is widely used in thin-film solar cells due to its excellent light absorption and efficient energy conversion.

- Infrared Sensitivity: TeCd thin films exhibit high sensitivity to infrared light, making them suitable for infrared detectors and thermal imaging devices.

- Stable Thin Films: TeCd films are chemically stable and durable, ensuring long-term performance in harsh environmental conditions.

- Efficient Energy Conversion: TeCd materials offer high energy conversion efficiency, particularly in solar and thermoelectric applications, providing reliable performance in energy devices.

-

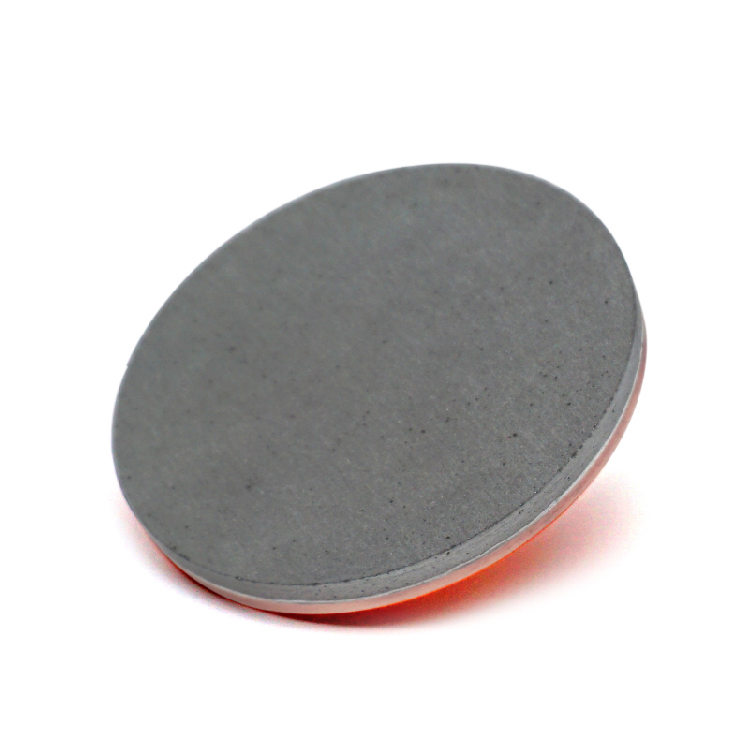

- High Purity: Ensures optimal film quality and performance.

- Excellent Electrical Conductivity: Suitable for advanced electronic applications.

- Thermal Stability: Resilient under high-temperature deposition processes.

- Layered Structure: Ideal for 2D material synthesis and related technologies.

- Customizable Specifications: Available in tailored sizes, shapes, and configurations.

-

- High Purity: Ensures superior thin-film quality with minimal impurities.

- Layered Structure: Supports the formation of ultra-thin films with excellent properties.

- Stable Composition: Reliable and consistent deposition outcomes.

- Versatile Application: Compatible with various sputtering systems and techniques.

- Customizable Options: Tailored targets for specific research and industrial requirements.

-

- High purity (≥99.99%).

- Direct bandgap for superior optoelectronic performance.

- Excellent optical transparency in visible to infrared spectra.

- Uniform pellet size for consistent deposition results.

- Customizable pellet sizes and packaging for specific applications.