Showing 37–48 of 56 results

-

- Exceptional Hardness: Provides superior durability and wear resistance.

- High Thermal Stability: Performs well under extreme temperatures.

- Electrical Conductivity: Suitable for electronic applications requiring conductive layers.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Purity: Ensures consistent thin-film quality and reliable performance.

-

- High Hardness: TiC is extremely hard, making it useful for coatings that require high wear resistance.

- Thermal Stability: TiC can withstand high temperatures, making it ideal for high-temperature deposition and coating processes.

- Corrosion Resistance: TiC coatings provide excellent resistance to oxidation and chemical corrosion, enhancing component longevity in harsh environments.

- Electrical Conductivity: As a conductive ceramic, TiC is suitable for applications requiring both mechanical strength and electrical conductivity.

-

- High Hardness: Ideal for cutting and abrasive applications.

- Superior Thermal Stability: Maintains integrity at elevated temperatures.

- Excellent Wear Resistance: Prolongs the life of coatings and components.

- Chemical Inertness: Resists corrosion in harsh chemical environments.

- Conductive Properties: Suitable for electrical and thermal applications.

- Customizable Particle Size: Available in nano and micron forms to meet specific application needs.

-

- High Hardness: TiC coatings provide excellent hardness, making them suitable for wear-resistant applications like cutting tools and dies.

- Corrosion Resistance: TiC films resist oxidation and corrosion, providing a protective barrier in harsh environments, including high-temperature applications.

- Thermal Stability: TiC has high thermal stability, making it ideal for coatings in high-temperature operations such as aerospace and automotive components.

- Electrical Conductivity: TiC exhibits good electrical conductivity, making it suitable for certain electronic and semiconductor applications where conductivity is critical.

- Chemical Resistance: TiC coatings offer chemical resistance, providing protective layers against corrosive agents and harsh chemicals.

-

- High Strength and Durability: Ensures reliable performance under mechanical stress.

- Excellent Corrosion Resistance: Suitable for harsh and corrosive environments.

- Biocompatibility: Ideal for medical applications such as implants and prosthetics.

- Customizable Ti-Mo Ratios: Tailored compositions for specific requirements.

- Wide Particle Size Range: Available from nanoscale to micrometer dimensions.

-

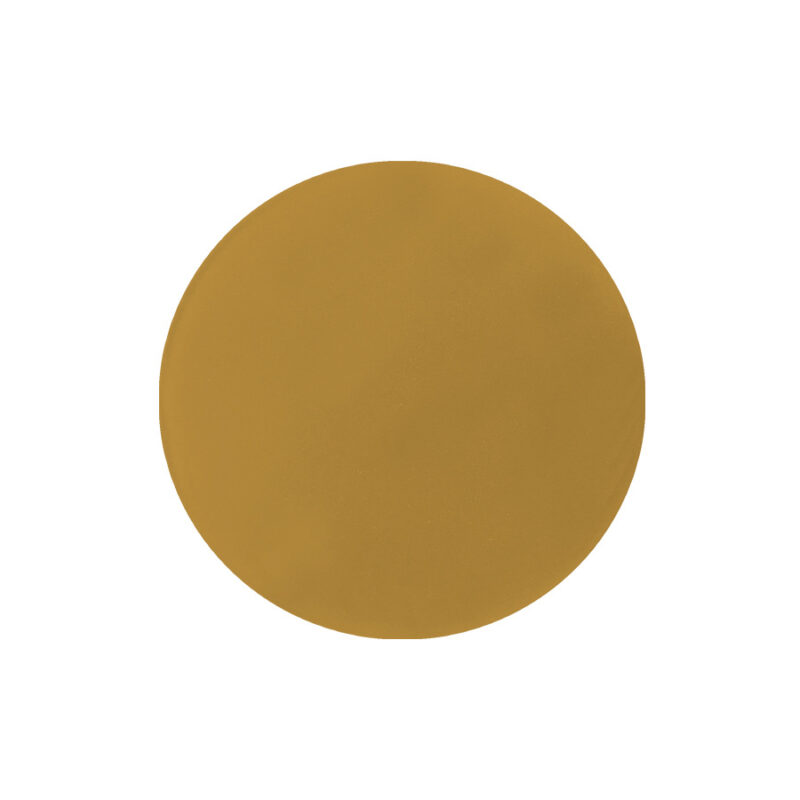

- High Hardness: TiN is extremely hard and resistant to wear, making it ideal for protective coatings in industrial applications.

- Chemical Stability: TiN is chemically inert and resistant to corrosion, which ensures durability in harsh environments.

- Golden Appearance: Its distinct golden color makes it a popular choice for decorative coatings.

- High Thermal Conductivity: TiN exhibits good thermal stability, making it suitable for high-temperature applications.

- Electrical Conductivity: TiN thin films are electrically conductive, making them useful in electronic and semiconductor applications.

-

- Hardness: Titanium Nitride has a high hardness level, making it ideal for wear-resistant applications.

- Corrosion Resistance: Exceptional resistance to oxidation and corrosion, extending the lifespan of components.

- High Thermal Stability: TiN maintains its stability even at high temperatures, making it suitable for high-temperature applications.

- Versatility: Can be used as a coating material or as a raw material for composites.

- Biocompatibility: Non-toxic and biocompatible, suitable for certain medical and biomedical applications.

-

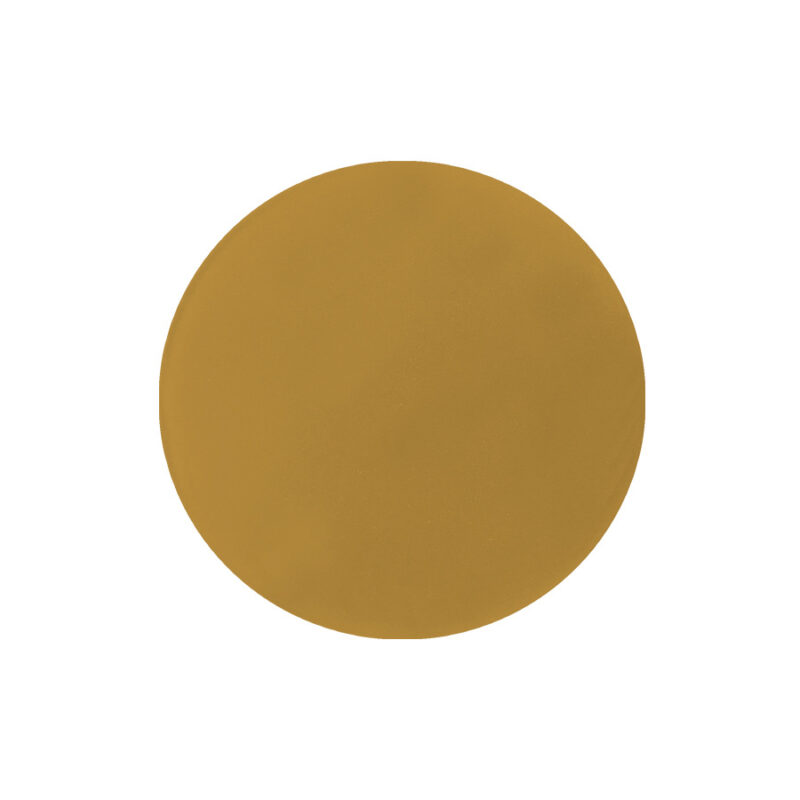

- High Hardness: TiN coatings are known for their exceptional hardness, making them ideal for cutting tools and components subject to high friction and stress.

- Corrosion Resistance: TiN provides excellent protection against corrosion and oxidation, extending the lifespan of coated parts and tools.

- High Temperature Stability: TiN remains stable at high temperatures, making it suitable for applications in high-temperature environments such as aerospace or industrial machinery.

- Good Electrical Conductivity: TiN is conductive and is often used in microelectronics as a barrier or adhesion layer in integrated circuits.

- Gold-Like Appearance: TiN has a bright gold color, making it popular for decorative applications and coatings in architectural elements and consumer products.

-

- High purity (≥99.9% or ≥99.99%).

- Excellent thermal and chemical stability.

- Uniform pellet size for consistent performance.

- Customizable specifications tailored to specific requirements.

-

- High Purity: Ensures superior film quality and minimal contamination.

- Stable Properties: Excellent thermal and chemical stability under deposition conditions.

- Customizable Forms: Available in various sizes and shapes to suit specific system requirements.

- Versatile Performance: Suitable for a wide range of thin-film applications.

- Durability: High mechanical strength for extended usability.

-

- High Refractive Index: Offers superior refractive index properties, making it ideal for optical coatings and enhancing light manipulation in optical devices.

- Broad Transparency Range: Transmits well in the UV, visible, and IR ranges, allowing for applications across a wide spectrum of light.

- Excellent Hardness and Stability: TiO₂ is chemically inert and provides good hardness, which makes it ideal for durable coatings.

- Photocatalytic Activity: Exhibits high efficiency in photocatalytic reactions under UV light, useful in environmental cleanup and antibacterial coatings.

- High Dielectric Constant: Enables its use in microelectronics for creating high-performance dielectric layers in capacitors and transistors.

-

- High Purity: Ensures superior performance across diverse applications.

- Excellent Photocatalytic Properties: Effective for environmental purification and self-cleaning surfaces.

- High Refractive Index: Ideal for optical coatings and pigments.

- UV Protection: Provides exceptional UV absorption for sunscreens and protective coatings.

- Thermal Stability: Performs consistently in high-temperature environments.

- Customizable Particle Size: Available in nano and micron sizes tailored to specific requirements.