Showing 1–12 of 24 results

-

- High Strength: The addition of vanadium significantly enhances the strength and hardness of the aluminum matrix.

- Lightweight: AlV powder provides a lightweight alternative to other high-strength alloys, making it ideal for aerospace and automotive applications.

- Good Corrosion Resistance: Offers excellent resistance to corrosion, suitable for harsh environmental conditions.

- Superior Machinability: The powder is easy to process, ensuring high precision and quality in final products.

- Enhanced Wear Resistance: The vanadium content enhances wear resistance, making it suitable for parts exposed to high friction or abrasive environments.

- Thermal Stability: Exhibits good thermal stability, allowing it to perform effectively in high-temperature applications.

-

- High Purity: Ensures consistent and reliable thin-film deposition.

- Superior Electrochemical Performance: Supports high energy density and stability.

- Customizable Options: Available in various sizes, shapes, and purity levels.

- Durable and Stable: Delivers reliable performance in demanding environments.

- Scalability: Suitable for both research-scale and industrial-scale applications.

-

- High Strength: NiV alloys exhibit exceptional mechanical strength, making them suitable for applications requiring durability and performance under stress.

- Corrosion Resistance: The addition of vanadium enhances the corrosion resistance of nickel, making NiV targets suitable for use in harsh environments and extending the life of thin films.

- Good Electrical Conductivity: NiV alloys maintain good electrical conductivity, which is essential for electronic and electrical applications.

- Versatility: The properties of NiV alloys can be tailored by adjusting the composition, allowing for customization to meet specific application requirements.

-

- High Strength: Offers superior tensile strength and toughness compared to standard nickel.

- Wear Resistance: Enhanced durability makes it ideal for high-friction applications.

- Corrosion Resistance: Good resistance to oxidation and chemical attack, extending the lifespan of coated components.

-

- High Conductivity: Excellent electrical conductivity makes SrVO₃ ideal for applications requiring transparent conductive materials.

- High Purity: Available in ≥99.5% purity, ensuring high-quality thin-film deposition.

- Stable Sputtering Performance: Reliable and consistent sputtering performance with minimal target degradation.

- Optical Transparency: Ideal for optoelectronic devices requiring both electrical conductivity and optical transparency.

- Customization: Targets can be made in various sizes and shapes to meet specific deposition system requirements.

-

- High Strength: TA15 powder provides superior mechanical strength, ensuring durability in high-stress environments.

- Excellent High-Temperature Resistance: With excellent thermal stability, it performs well in extreme temperature conditions.

- Superior Fatigue Resistance: Offers excellent resistance to fatigue, making it suitable for dynamic and cyclic loading applications.

- Corrosion Resistance: TA15 exhibits excellent corrosion resistance, especially in harsh environments such as marine and chemical industries.

- Weldability: The alloy offers good weldability, ensuring high-quality joins in critical structural components.

- Biocompatibility: Safe for medical applications, ensuring no harmful reactions with the body.

-

- Superior Strength-to-Weight Ratio: TC4 offers exceptional strength while maintaining a lightweight profile, making it ideal for demanding applications.

- Corrosion Resistance: Resistant to corrosion in various environments, particularly in harsh aerospace and marine conditions.

- Biocompatibility: Safe for medical and implant applications due to its non-toxic and biocompatible properties.

- Excellent Weldability: The alloy’s composition allows for good weldability, ensuring reliable performance in critical applications.

- High Durability: Resistant to wear and fatigue, making it suitable for long-lasting and high-performance products.

-

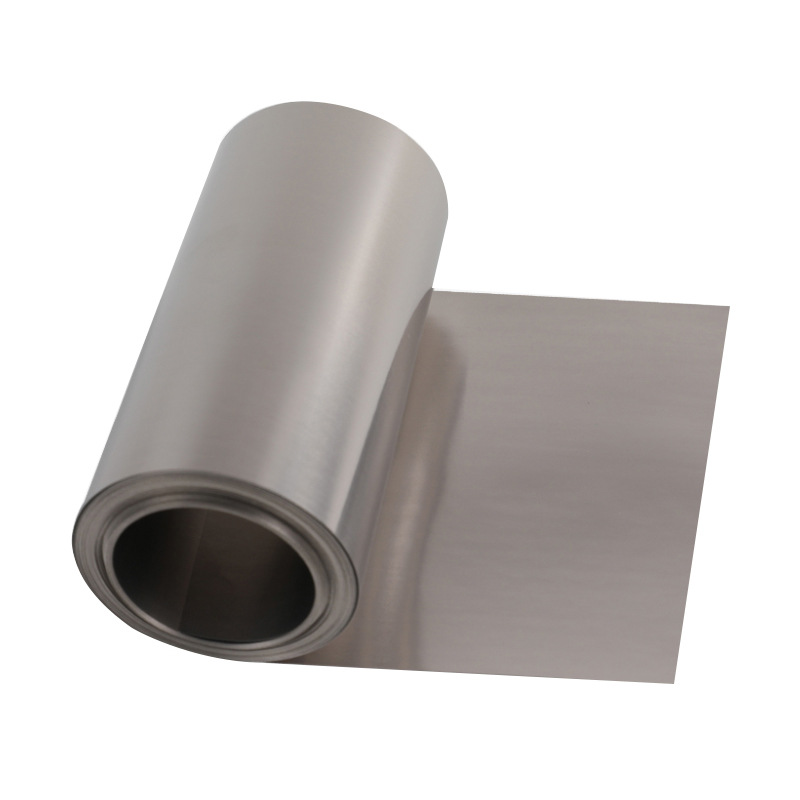

- High Strength-to-Weight Ratio: Vanadium foil is lightweight yet incredibly strong, making it suitable for aerospace and structural applications.

- Corrosion Resistance: Vanadium exhibits excellent resistance to oxidation and corrosion, especially in harsh environments.

- High Melting Point: With a melting point of 1,910°C (3,470°F), vanadium foil is highly resistant to heat, ideal for high-temperature applications.

- Ductility: Vanadium foil is ductile and can be processed into thin sheets or complex shapes without losing its structural integrity.

- Thermal and Electrical Conductivity: Vanadium offers good thermal and electrical conductivity, suitable for energy storage and electrical applications.

- Compatibility with Alloys: Vanadium can enhance the strength and wear resistance of other metals when used as an alloying element.

-

- High Strength & Corrosion Resistance: Vanadium offers excellent durability, making it suitable for applications in extreme environments.

- High Purity: Available in high-purity forms (≥ 99.9%) for optimal thin film deposition with minimal contamination.

- Good Evaporation Properties: Vanadium has a melting point of 1910°C, allowing efficient vapor deposition in high-temperature processes.

- Versatile Application Range: Used in various fields such as electronics, optics, and renewable energy storage, making it a versatile evaporation material.

-

- High Purity: Ensures superior performance in demanding applications.

- Corrosion Resistance: Resists oxidation and degradation in harsh environments.

- High Strength-to-Weight Ratio: Lightweight yet strong, ideal for aerospace and structural applications.

- Thermal and Electrical Conductivity: Efficient in thermal and electrical energy management.

- Customizable Particle Sizes: Adaptable to specific industrial requirements.

-

Vanadium sputtering targets are essential in industries that require strong, corrosion-resistant, and stable thin films. Their use in semiconductors, aerospace, superconducting materials, and energy storage highlights the versatility and importance of vanadium in advanced technology applications.

-

- High Strength and Toughness: Vanadium wire has remarkable strength and toughness, which makes it ideal for applications requiring high endurance and resistance to mechanical stress.

- Corrosion Resistance: Vanadium is highly resistant to corrosion, making it suitable for use in harsh environments, including high-temperature and corrosive applications.

- High Melting Point: Vanadium wire has a high melting point of approximately 1910°C, allowing it to maintain its structural integrity under extreme temperature conditions.

- Good Thermal Conductivity: Vanadium wire exhibits good thermal conductivity, which helps in heat dissipation, especially in high-temperature environments.

- Ductility and Malleability: While strong and durable, vanadium wire remains ductile, which allows it to be easily processed and shaped for a wide range of applications.

- Magnetic Properties: Vanadium has relatively low magnetic susceptibility, which is beneficial in specific industrial and scientific applications that require minimal magnetic interference.