-

- Lightweight and Strong: Combines low density with excellent mechanical properties.

- Superior Thermal Stability: Maintains integrity at elevated temperatures.

- High Oxidation Resistance: Ideal for extreme thermal and environmental conditions.

- Customizable Al-Y Ratios: Tailored to specific industry requirements.

- Versatile Particle Sizes: From nanoscale to micrometer ranges for diverse applications.

-

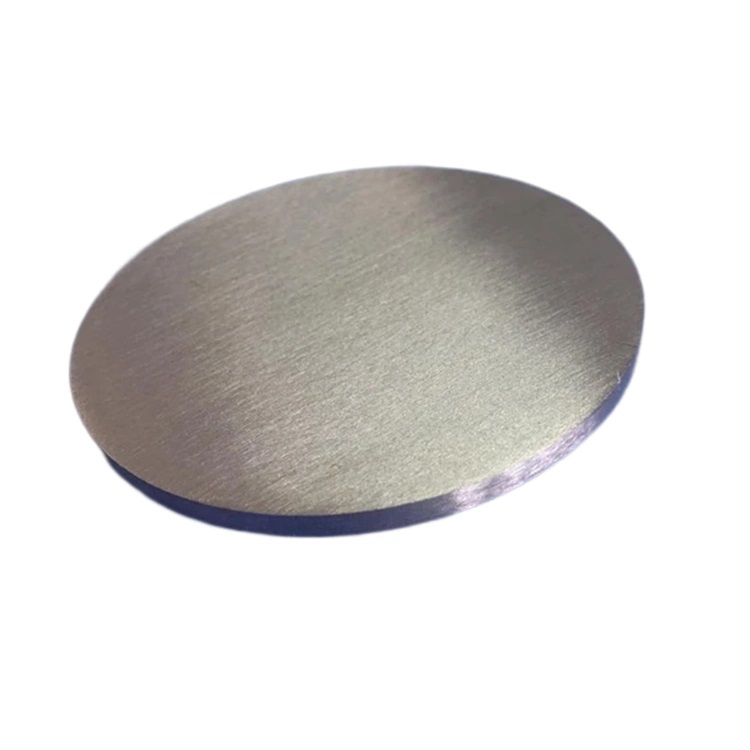

- High Purity: Yttrium pellets are typically available in purity levels of 99.9% or higher, ensuring high-quality and defect-free thin films.

- Thermal Stability: Yttrium’s high melting point and thermal resistance make it suitable for high-temperature applications.

- Versatile Deposition: Suitable for thermal and e-beam evaporation, yttrium can be used to create smooth, uniform coatings.

- Enhancing Material Properties: Yttrium’s role as an additive improves the performance of materials, especially in electronics and ceramics.

-

- High Temperature Resistance: Yttrium has excellent thermal stability, making it valuable in materials exposed to extreme temperatures.

- Corrosion Resistance: Yttrium improves the corrosion resistance of alloys and ceramics, particularly in environments with aggressive chemicals or high heat.

- Magnetic Properties: Yttrium is used in yttrium iron garnets (YIG), which have magnetic properties useful in microwave filters and resonators.

- Lightweight: Yttrium is relatively light, making it ideal for high-strength, lightweight alloys used in industries like aerospace.

-

Yttrium sputtering targets are essential for producing thin films with high thermal stability, excellent corrosion resistance, and unique electronic or optical properties. Their applications in semiconductors, superconductors, optoelectronics, and advanced materials highlight yttrium’s importance in cutting-edge technology.

-

- High purity (≥99.9% or ≥99.99%).

- Excellent thermal and chemical stability.

- Uniform pellet size for consistent deposition.

- Customizable specifications to meet diverse application needs.

-

- High Purity: ≥99.9% purity for consistent performance and reliability in sensitive applications.

- Excellent Optical Properties: Suitable for laser and phosphor applications.

- Thermal Stability: Can withstand high temperatures without degradation.

- Chemical Stability: Resists corrosion and oxidation, enhancing durability in harsh environments.

- Superior Dielectric Properties: Ideal for use in electronic and energy storage applications.

- Fine Particle Size: Available in various particle sizes for different manufacturing processes.

-

- High Thermal Stability: Y₂O₃ maintains stability even at high temperatures, making it suitable for applications that require heat resistance.

- Wide Bandgap: Its wide bandgap allows Y₂O₃ to function effectively as an insulator and dielectric in electronic devices.

- Excellent Optical Properties: Y₂O₃ exhibits high transmittance in the visible and infrared ranges, making it ideal for optical coatings and laser technologies.

- Corrosion Resistance: Y₂O₃ offers excellent resistance to chemical corrosion, making it valuable in environments where exposure to aggressive chemicals is common.

-

- Excellent Magnetic Properties: High-quality films with strong magneto-optic effects.

- Dielectric Stability: Low-loss properties for microwave and optical applications.

- Thermal Resistance: Operates reliably under high temperatures.

- High Purity: Ensures consistent film quality and performance.

- Customizable: Tailored compositions and dimensions to meet specific requirements.

-

- High Purity: ≥99.9% purity, ensuring high performance and minimal contamination in sensitive applications.

- Electrical Conductivity: Exceptional conductivity makes it ideal for use in electrical and electronic components.

- Thermal Stability: High resistance to thermal shock and high-temperature environments, retaining properties in extreme conditions.

- Chemical Resistance: Resistant to oxidation and corrosion, enhancing the longevity and reliability of components.

- Durability: Excellent wear resistance and mechanical strength, making it suitable for heavy-duty applications.

- Versatile Particle Size: Available in nano to micron-sized powders, allowing for customization based on specific application requirements.

-

- Wide Transmission Range: Offers excellent transparency from UV (down to 200 nm) to IR (up to 10 µm), making it versatile for various optical applications.

- Low Refractive Index: Has a low refractive index (~1.5), which makes it a good material for anti-reflective coatings.

- High Chemical Stability: YF₃ is chemically inert, ensuring long-lasting coatings that resist corrosion, oxidation, and environmental wear.

- Low Absorption: Provides coatings with minimal light absorption, especially important in high-energy optical and laser systems.

- Thermal Stability: Offers good thermal stability, making it suitable for high-temperature deposition processes.

-

- Low Refractive Index: YF₃ films offer a low refractive index, making them ideal for anti-reflective coatings and optical thin films.

- High Purity: Available in ≥99.9% purity, ensuring clean deposition and minimal contamination in thin-film applications.

- Chemical Resistance: Resistant to acid and alkali, making it suitable for harsh environments.

- Optical Transparency: High optical transparency in the UV and visible spectra, enhancing the performance of optical coatings.

- Durability: Offers excellent mechanical properties and resistance to environmental degradation, ensuring long-term stability.