Showing 1–12 of 21 results

-

- Soft Magnetic Properties: CoTaZr alloy offers excellent soft magnetic properties, including high permeability and low coercivity, making it suitable for data storage and magnetic sensor applications.

- Thermal Stability: The presence of tantalum in the alloy enhances its thermal stability, allowing it to maintain performance at elevated temperatures.

- Corrosion Resistance: The addition of zirconium contributes to improved corrosion resistance, making CoTaZr thin films durable in challenging environmental conditions, ensuring longevity in devices.

- High Saturation Magnetization: CoTaZr alloys provide high saturation magnetization, enabling efficient energy storage and transfer in magnetic thin films.

- Low Losses: The alloy exhibits low magnetic and electrical losses, making it ideal for applications requiring high efficiency, such as power electronics and transformers.

-

- High Corrosion Resistance: The addition of zirconium and titanium enhances the alloy’s resistance to corrosion, making it suitable for harsh environments, including semiconductor processing and aerospace applications.

- Thermal Stability: Molybdenum’s high melting point, combined with the stability of zirconium and titanium, allows MoZrTi thin films to maintain performance at elevated temperatures.

- Electrical Conductivity: MoZrTi alloy thin films provide good electrical conductivity, ideal for applications in electronic devices such as transistors and semiconductors.

- Mechanical Strength: The alloy offers a combination of strength and toughness, ensuring durability in wear-resistant coatings and industrial components.

- Oxidation Resistance: MoZrTi thin films resist oxidation, which is critical for maintaining performance over long periods, particularly in high-temperature and oxidative environments.

-

- High Strength: The alloy provides exceptional mechanical strength, making it suitable for demanding applications.

- Temperature Resistance: Offers good resistance to high temperatures, maintaining performance under thermal stress.

- Corrosion Resistance: Resistant to oxidation and corrosion, enhancing the lifespan of components in harsh environments.

-

- High Piezoelectric Coefficient: Enables efficient conversion of mechanical energy to electrical energy and vice versa.

- Stable Dielectric Properties: Ensures reliable performance in high-frequency applications.

- Customizable Compositions: Tailored Zr/Ti ratios to meet specific functional requirements.

- High Purity and Uniformity: Ensures consistent film deposition with minimal defects.

- Versatile Deposition: Compatible with RF and DC magnetron sputtering systems.

-

- Superior Mechanical Strength: The combination of titanium, zirconium, hafnium, and niobium results in exceptional mechanical strength, making TiZrHfNb thin films suitable for applications exposed to extreme stress and high temperatures.

- High Corrosion Resistance: This alloy’s ability to resist oxidation and corrosion, particularly in harsh and high-temperature environments, makes it ideal for aerospace, energy, and medical applications.

- Thermal Stability: TiZrHfNb alloy thin films retain their structural integrity at elevated temperatures, making them suitable for use in high-heat applications, such as power generation systems and aerospace components.

- Wear Resistance: The combination of hafnium and niobium in the alloy enhances wear resistance, making it perfect for applications requiring durable coatings, such as industrial tools and mechanical parts.

- Biocompatibility: TiZrHfNb alloy is biocompatible, making it ideal for medical devices and implants where long-term stability and resistance to body fluids are required.

-

- Exceptional Mechanical Properties: Outstanding strength and ductility even at high temperatures.

- High-Temperature Stability: Retains structural integrity under extreme thermal conditions.

- Corrosion and Oxidation Resistance: Suitable for harsh and reactive environments.

- High Entropy Alloy: Unique multi-element composition for enhanced material performance.

- Customizable Particle Sizes: Nano to micrometer scales for diverse applications.

-

- High Melting Point: Zirconium foil has a melting point of approximately 1855°C, making it ideal for high-temperature applications.

- Corrosion Resistance: Exceptional resistance to corrosion, particularly in acids, alkalis, and saltwater environments, making it highly durable in harsh conditions.

- Low Neutron Absorption: Ideal for use in nuclear reactors as it exhibits low neutron absorption, contributing to its application in nuclear fuel cladding.

- Thermal Stability: Maintains structural integrity even under extreme temperature conditions, making it suitable for use in high-heat environments.

- Malleability: The material is highly malleable, allowing it to be formed into thin sheets, foils, and complex shapes without compromising its performance.

- Lightweight and Strong: Zirconium foil offers a balance of low density and high strength, making it suitable for applications where both strength and lightness are required.

- Biocompatibility: Non-toxic and biocompatible, making it suitable for use in medical and pharmaceutical applications.

-

- High Purity: Zirconium pellets are available in high purity, typically ≥ 99.9%, ensuring reliable thin film deposition.

- Corrosion Resistance: Excellent resistance to corrosion, particularly in aggressive chemical environments.

- Thermal Stability: Zirconium’s high melting point (1,855°C) makes it suitable for high-temperature applications.

- Oxidation Resistance: Forms a stable oxide layer, improving the durability of films in reactive environments.

-

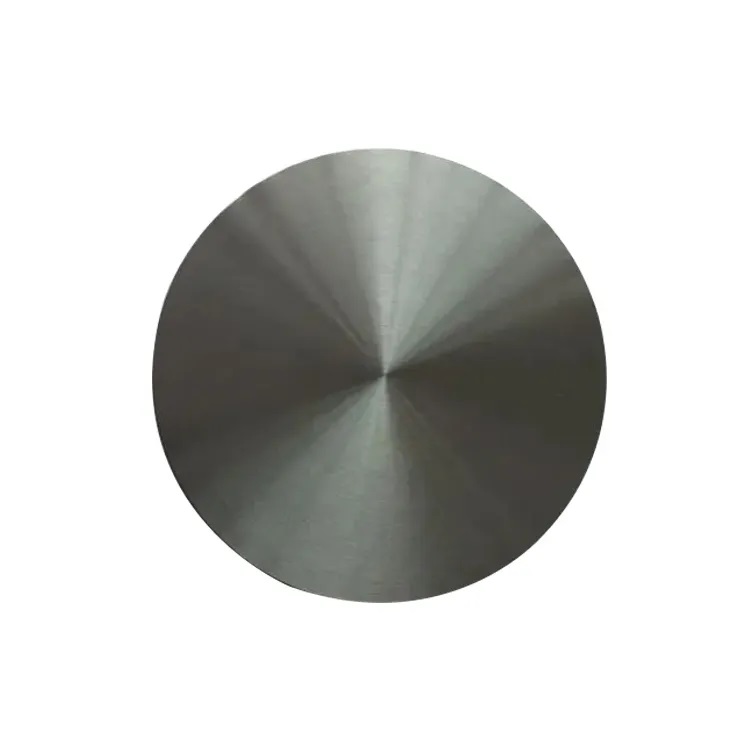

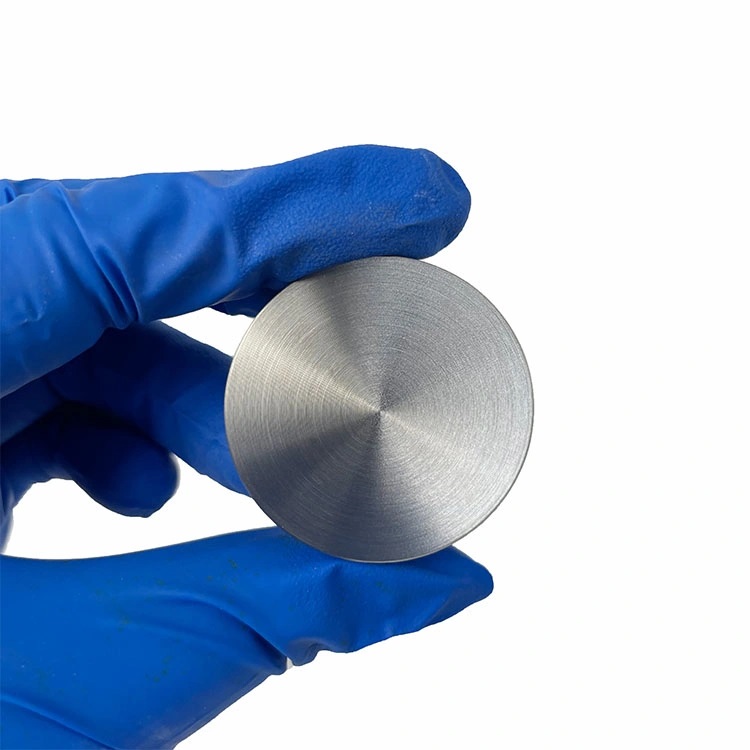

Zirconium sputtering targets are critical for industries that require materials with exceptional corrosion resistance, high-temperature stability, and biocompatibility, making them indispensable in electronics, aerospace, nuclear, and medical applications.

-

- High Hardness: ZrB₂ is an extremely hard material, making it ideal for wear-resistant and protective coatings.

- Thermal Stability: ZrB₂ sputtering targets produce thin films that can withstand high temperatures, making them suitable for use in harsh environments.

- High Thermal Conductivity: ZrB₂ has excellent thermal conductivity, which is advantageous for heat management in high-performance coatings.

- Chemical Resistance: ZrB₂ thin films are resistant to chemical attack, especially in high-temperature, corrosive environments.

-

- High Melting Point: ZrC has an extremely high melting point (~3,530°C), making it suitable for high-temperature applications.

- Excellent Hardness and Wear Resistance: It provides outstanding hardness, making it ideal for protective coatings and applications requiring high durability.

- Good Thermal and Electrical Conductivity: ZrC exhibits metallic-like conductivity, which is beneficial for electrical applications and high-heat environments.

- Corrosion and Oxidation Resistance: Highly resistant to chemical attack, corrosion, and oxidation, even in harsh conditions.

- Low Density: Compared to other refractory materials, ZrC has a relatively low density, making it advantageous in aerospace applications where weight is a critical factor.

-

- High Purity: Purity levels of ≥99% ensure reliability in critical applications.

- Thermal Stability: Exceptional resistance to oxidation and thermal shock.

- Superior Hardness: Ideal for cutting and wear-resistant tools.

- High Melting Point: Withstands extreme temperatures (~3540°C).

- Customizable Particle Sizes: Available in nano (<100 nm) and micro (1–50 µm) grades or customized.