AlCu (Aluminum Copper) Sputtering Targets

- Good Electrical Conductivity: The combination of aluminum and copper offers excellent electrical conductivity, making it ideal for use in electronic and photovoltaic applications.

- Thermal Stability: AlCu films have excellent thermal stability, which is essential for applications in environments with varying temperatures, such as in electronics or solar cells.

- Corrosion Resistance: The alloy exhibits good resistance to corrosion, enhancing the durability and longevity of thin films.

- Low Resistance: The low resistivity of AlCu makes it ideal for interconnects and conductive layers in semiconductor and photovoltaic devices.

- High Deposition Rate: AlCu sputtering targets offer a high deposition rate, ensuring efficient production of high-quality thin films.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Aluminum Copper (AlCu) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

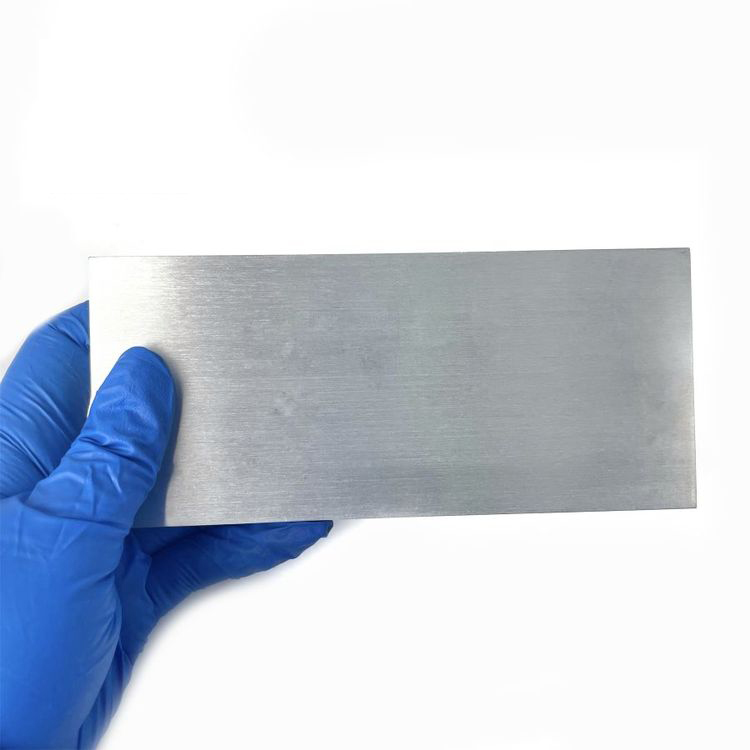

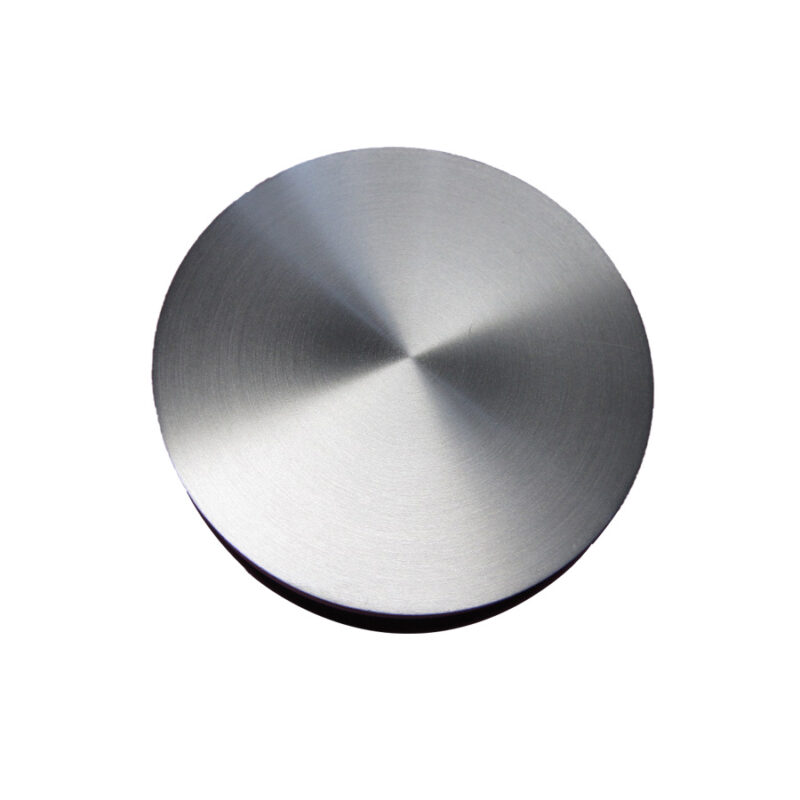

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Aluminum Copper (AlCu) sputtering targets are composite targets made from a combination of aluminum and copper. These targets are widely used in the production of thin films for a variety of applications, including electronics, photovoltaic devices, and semiconductor fabrication. The alloy’s properties, including good electrical conductivity, thermal stability, and corrosion resistance, make it a popular choice for manufacturing conductive layers, interconnects, and metallization layers in various electronic devices.

Key Applications

- Semiconductor Manufacturing: AlCu thin films are commonly used as interconnects in semiconductor devices due to their excellent electrical conductivity and low resistance.

- Photovoltaics: AlCu films are used in solar cells, particularly for creating metal contacts in photovoltaic devices, ensuring high efficiency and performance.

- Electronics and Optoelectronics: AlCu is utilized for metallization layers in electronic devices, such as integrated circuits, LEDs, and optoelectronic components.

- Microelectronics: AlCu sputtering targets are employed in the deposition of thin films for microelectromechanical systems (MEMS) and microelectronics, where high precision and excellent conductivity are required.

- Hard Disk Drives: AlCu alloys are used in magnetic and non-magnetic applications, such as magnetic storage media, offering better resistance to wear and heat.

- Automotive and Aerospace: Due to its thermal and electrical properties, AlCu is also used in aerospace and automotive applications for coatings and electrical systems.

Features and Benefits

- Good Electrical Conductivity: The combination of aluminum and copper offers excellent electrical conductivity, making it ideal for use in electronic and photovoltaic applications.

- Thermal Stability: AlCu films have excellent thermal stability, which is essential for applications in environments with varying temperatures, such as in electronics or solar cells.

- Corrosion Resistance: The alloy exhibits good resistance to corrosion, enhancing the durability and longevity of thin films.

- Low Resistance: The low resistivity of AlCu makes it ideal for interconnects and conductive layers in semiconductor and photovoltaic devices.

- High Deposition Rate: AlCu sputtering targets offer a high deposition rate, ensuring efficient production of high-quality thin films.

Specifications

- Composition: Typically consists of 90% Aluminum and 10% Copper, but custom compositions are available depending on specific requirements.

- Purity: Available in various purity grades, typically ≥ 99.9%, with options for ultra-high purity for sensitive applications.

- Size: Custom sizes ranging from 50 mm to 200 mm in diameter, with thicknesses typically ranging from 1 mm to 10 mm.

- Density: Approximately 2.7 g/cm³ for the aluminum content; density may vary slightly based on the alloy composition.

- Form: Disc-shaped sputtering targets are available, with options for custom shapes and sizes to suit specific deposition systems.

- Sputtering Conditions: Suitable for both DC and RF sputtering systems, depending on the specific deposition needs.

Customization Options

- Size & Shape: Custom sizes and shapes are available for specific deposition processes or sputtering systems.

- Purity & Composition: AlCu sputtering targets can be customized with varying aluminum-to-copper ratios to meet the specific needs of a wide range of applications.

- Surface Treatment: Polished surfaces for enhanced sputtering performance and thin-film uniformity.

- Thickness & Density: Custom thicknesses and densities are available for specific deposition requirements.

For more information on AlCu sputtering targets, including customization options and availability, contact our team. We offer tailored solutions for your thin-film deposition requirements in semiconductor, photovoltaic, and electronics industries.