AlMo (Aluminum Molybdenum) Pellets Granules Evaporation Materials

- Enhanced Strength: Molybdenum contributes to higher strength and stability at elevated temperatures.

- Good Thermal Conductivity: Provides effective heat dissipation in electronic applications.

- Corrosion Resistance: Offers improved resistance against oxidation and wear.

- Versatile Deposition: Compatible with thermal evaporation and sputtering techniques.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Aluminum Molybdenum |

| Purity | 99.5% – 99.999% / 2N5 3N 3N5 4N 4N5 5N |

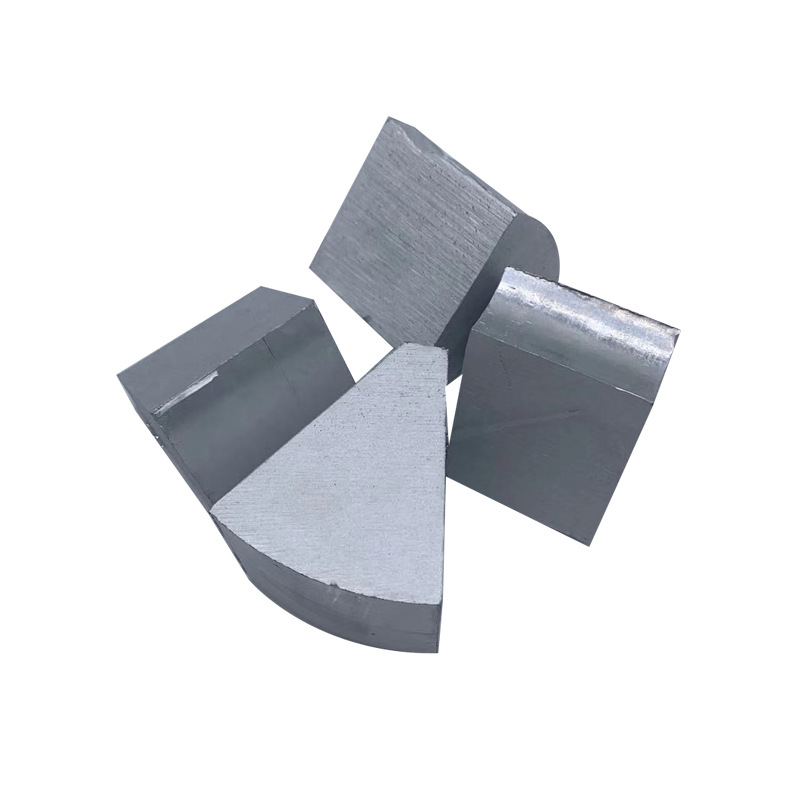

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

AlMo (Aluminum Molybdenum) pellets are an alloy of aluminum and molybdenum, used as evaporation materials for thin-film deposition. This combination offers unique properties beneficial for various high-performance applications.

Key Applications:

- Thin-Film Coatings: Utilized in creating thin films for optical devices and electronics.

- Electrical Contacts: Suitable for applications requiring low electrical resistance.

- High-Temperature Applications: Effective in environments where thermal stability is crucial.

- Aerospace Components: Employed in aerospace for lightweight yet strong materials.

Features:

- Enhanced Strength: Molybdenum contributes to higher strength and stability at elevated temperatures.

- Good Thermal Conductivity: Provides effective heat dissipation in electronic applications.

- Corrosion Resistance: Offers improved resistance against oxidation and wear.

- Versatile Deposition: Compatible with thermal evaporation and sputtering techniques.

Specifications:

- Material Composition: Aluminum-Molybdenum Alloy

- Purity: Typically ≥ 99.5%

- Form: Pellets

- Size: Generally 1-6 mm in diameter (custom sizes available)

- Melting Point: Approximately 660°C (Al) and 2623°C (Mo)

- Density: About 2.7 g/cm³ (Al) and 10.2 g/cm³ (Mo)

- Deposition Methods: Suitable for thermal evaporation and sputtering.

- Applications: Thin-film coatings, electrical contacts, high-temperature environments, aerospace components.

Tinsan Materials offers high-purity AlMo (Aluminum-Molybdenum) pellets for evaporation. Ideal for thin-film coatings, electrical contacts, and high-temperature applications. Available in custom sizes with ≥ 99.5% purity for enhanced strength and conductivity.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.