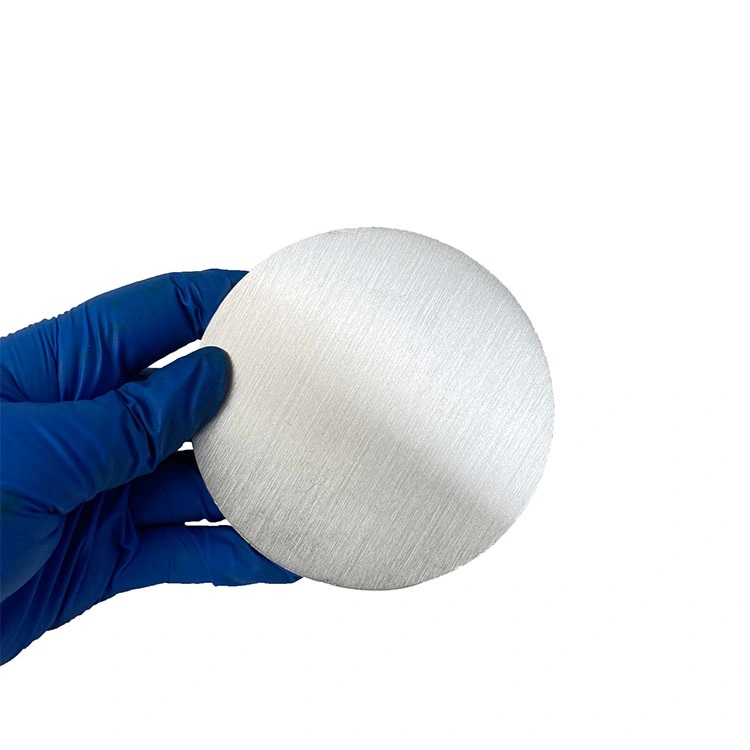

Al Aluminium Sputtering Target

Aluminum (Al) sputtering targets are essential for industries that rely on high conductivity, reflectivity, and corrosion resistance, making them indispensable in electronics, optics, aerospace, and packaging applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Aluminium (Al) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 1000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Aluminum (Al) sputtering targets are essential for industries that rely on high conductivity, reflectivity, and corrosion resistance, making them indispensable in electronics, optics, aerospace, and packaging applications.

Key Features:

- Purity: Aluminum sputtering targets are typically available in high purity levels, such as 99.99% (4N) or higher, ensuring the deposition of high-quality and consistent films.

- Shapes and Sizes: These targets are offered in various forms, including discs, plates, and custom shapes, to accommodate different sputtering systems and specific application requirements.

Applications:

- Electronics: Aluminum is extensively used in the electronics industry for interconnects in integrated circuits (ICs), thin-film transistors (TFTs), and other electronic components, where its high electrical conductivity and low cost are advantageous.

- Reflective Coatings: Aluminum is used in reflective coatings for mirrors, optical instruments, and lighting fixtures due to its high reflectivity across the visible and infrared spectra.

- Packaging: In the packaging industry, aluminum thin films are applied to plastic or paper substrates to create barrier coatings that protect against moisture, light, and air.

- Energy: Aluminum sputtering targets are used in the production of thin-film solar cells, where aluminum layers are applied as back reflectors to enhance light absorption and improve efficiency.

- Aerospace: Aluminum coatings are used in aerospace applications for thermal and corrosion resistance, as well as in lightweight components that require high strength-to-weight ratios.

Customization Options:

- Thickness: The thickness of the aluminum coating can be precisely controlled during the sputtering process, allowing for customized solutions to meet specific application needs.

- Alloys: Aluminum sputtering targets can be produced as pure aluminum or in alloyed forms, such as aluminum-silicon (Al-Si) or aluminum-copper (Al-Cu), to achieve desired film properties like improved wear resistance or specific electrical characteristics.

- Backing Plates: Aluminum targets can be bonded to backing plates made of materials like copper or molybdenum to enhance thermal conductivity and mechanical stability during sputtering.

Aluminum sputtering targets are widely used in physical vapor deposition (PVD) processes to create thin aluminum films on various substrates. Aluminum is known for its excellent electrical conductivity, light weight, corrosion resistance, and reflective properties, making it a key material in industries such as electronics, optics, and aerospace.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.