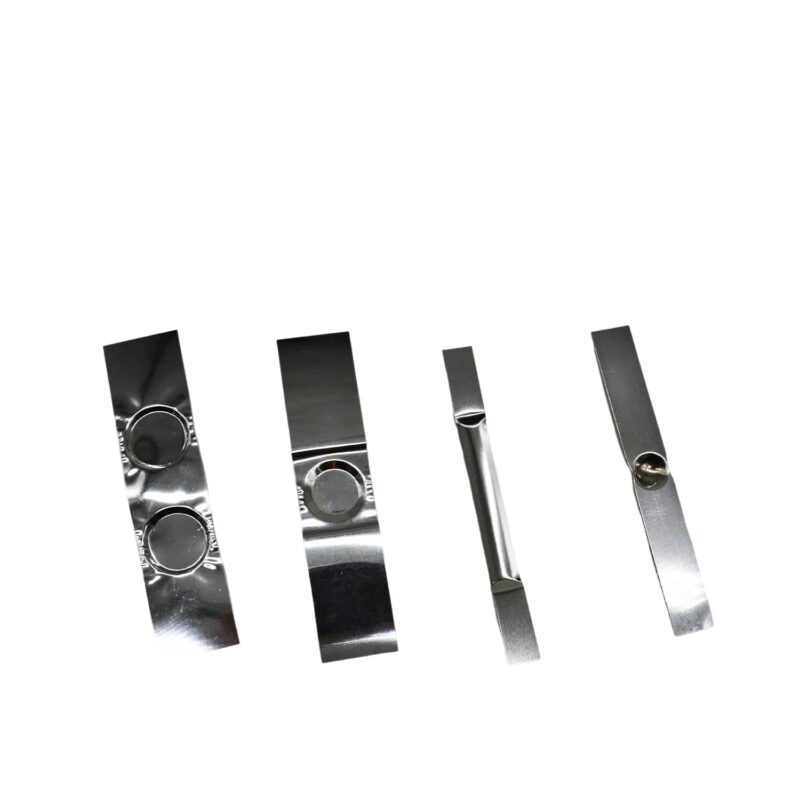

Au Gold Foil

- High Purity: Gold foil is typically made from high-purity gold, often 99.99% pure or greater. The high purity ensures excellent performance in sensitive applications such as electronics and medical devices.

- Malleability and Ductility: Gold is one of the most malleable and ductile metals, which means it can be easily shaped or stretched without breaking. This property makes gold foil ideal for precise applications where flexibility and thinness are required.

- Excellent Electrical Conductivity: Gold foil has superior electrical conductivity, making it ideal for use in high-performance electronic devices such as connectors, semiconductors, and microelectronics.

- Corrosion and Oxidation Resistance: Gold’s natural resistance to corrosion and oxidation makes gold foil an excellent choice for applications exposed to harsh environments. It does not tarnish, rust, or corrode, ensuring long-term durability and reliability.

- Thermal Conductivity: Gold foil offers high thermal conductivity, which is useful in heat dissipation applications in electronic devices and aerospace technology, where managing heat is critical.

- Biocompatibility: Gold is biocompatible, meaning it is safe for use in medical and dental applications. It does not cause adverse reactions in the body, making it ideal for implants and other medical devices.

- Reflectivity: Gold foil has excellent optical reflectivity, especially in infrared wavelengths, making it valuable in specialized coatings and mirrors for scientific instruments, telescopes, and other optical applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Gold foil is a thin, flexible sheet of high-purity gold that is widely used in various industrial, technological, and decorative applications. Due to its exceptional properties, gold foil is a valuable material in fields such as electronics, aerospace, medical devices, and art. The unique combination of electrical conductivity, corrosion resistance, malleability, and biocompatibility makes gold foil an essential material for many cutting-edge technologies.

Properties of Gold Foil

- High Purity: Gold foil is typically made from high-purity gold, often 99.99% pure or greater. The high purity ensures excellent performance in sensitive applications such as electronics and medical devices.

- Malleability and Ductility: Gold is one of the most malleable and ductile metals, which means it can be easily shaped or stretched without breaking. This property makes gold foil ideal for precise applications where flexibility and thinness are required.

- Excellent Electrical Conductivity: Gold foil has superior electrical conductivity, making it ideal for use in high-performance electronic devices such as connectors, semiconductors, and microelectronics.

- Corrosion and Oxidation Resistance: Gold’s natural resistance to corrosion and oxidation makes gold foil an excellent choice for applications exposed to harsh environments. It does not tarnish, rust, or corrode, ensuring long-term durability and reliability.

- Thermal Conductivity: Gold foil offers high thermal conductivity, which is useful in heat dissipation applications in electronic devices and aerospace technology, where managing heat is critical.

- Biocompatibility: Gold is biocompatible, meaning it is safe for use in medical and dental applications. It does not cause adverse reactions in the body, making it ideal for implants and other medical devices.

- Reflectivity: Gold foil has excellent optical reflectivity, especially in infrared wavelengths, making it valuable in specialized coatings and mirrors for scientific instruments, telescopes, and other optical applications.

Advantages of Gold Foil

- Durability and Longevity: Gold foil’s resistance to corrosion, oxidation, and tarnishing contributes to its exceptional durability. It maintains its appearance and performance over time, making it ideal for long-lasting applications.

- Flexibility and Thinness: The extreme malleability of gold allows it to be manufactured into extremely thin foils, with thicknesses down to a few micrometers. This flexibility makes gold foil perfect for delicate applications requiring precision.

- Superior Conductivity: As a highly conductive metal, gold foil is used extensively in electrical and electronic components where high performance is critical, such as connectors, semiconductors, and solar cells.

- Ease of Fabrication: Gold foil can be easily fabricated into a variety of shapes and sizes, enabling precise customization for specific applications. It is easy to form and manipulate without cracking or breaking, even in intricate designs.

- Aesthetic Appeal: Gold foil has an attractive metallic sheen, making it a popular choice in decorative and artistic applications, including gilding, jewelry, and other luxury items.

- Non-reactive: Gold foil is non-reactive, which makes it a preferred material in environments where chemical reactions could compromise other materials. It is commonly used in sensitive chemical processes, electronics, and medical fields.

Applications of Gold Foil

- Electronics and Electrical Components: Gold foil is extensively used in the electronics industry, where its superior electrical conductivity and resistance to corrosion make it ideal for components such as connectors, contacts, semiconductors, and microcircuits. Gold foil is particularly valuable in high-performance applications such as satellites and telecommunications.

- Aerospace and Aviation: In aerospace, gold foil is used in critical applications like spacecraft and satellites for thermal control and reflective coatings. Its resistance to oxidation and ability to reflect infrared radiation make it an ideal material for spacecraft insulation.

- Medical Devices and Implants: Due to its biocompatibility, gold foil is commonly used in medical applications such as dental restorations, implants, and stents. It is also used in diagnostics and medical imaging devices where reliability and biocompatibility are essential.

- Gilding and Decorative Arts: Gold foil is widely used in decorative arts for gilding, a process in which a thin layer of gold is applied to various surfaces such as wood, metal, or glass. This gives objects a luxurious and aesthetically appealing finish. Gold foil is also used in the production of high-end jewelry.

- Scientific and Optical Instruments: Gold foil is employed in scientific instruments, including telescopes, microscopes, and spectrometers. Its high reflectivity makes it an essential material in mirrors and optical coatings, especially in infrared applications.

- Solar Cells and Photovoltaics: Gold foil is used in the manufacturing of solar cells and photovoltaic devices. Its high conductivity and resistance to corrosion help enhance the efficiency and durability of solar energy systems, contributing to longer-lasting and more efficient energy harvesting.

- Packaging and Branding: In the luxury goods industry, gold foil is often used in packaging, branding, and product labels. Its elegant appearance adds a touch of luxury to high-end products, such as cosmetics, perfumes, and alcoholic beverages.

- Food and Beverage: Gold leaf, a form of gold foil, is used as a decoration in high-end culinary applications. It is edible and used to enhance the appearance of gourmet dishes, chocolates, and beverages.

Customization and Manufacturing of Gold Foil

Gold foil is available in various thicknesses, sizes, and forms to suit specific needs. Manufacturers can customize gold foil to meet the precise requirements of different applications, whether it’s for a delicate art project, a high-tech electronic device, or a medical implant. The foil is often available in rolls, sheets, or discs and can be further processed into intricate shapes or patterns.

Tinsan Materials offers gold foil in various grades and custom specifications to meet the diverse demands of our clients in electronics, aerospace, medical, and decorative industries. We ensure that our gold foil is produced to the highest standards of purity, thickness, and performance.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.