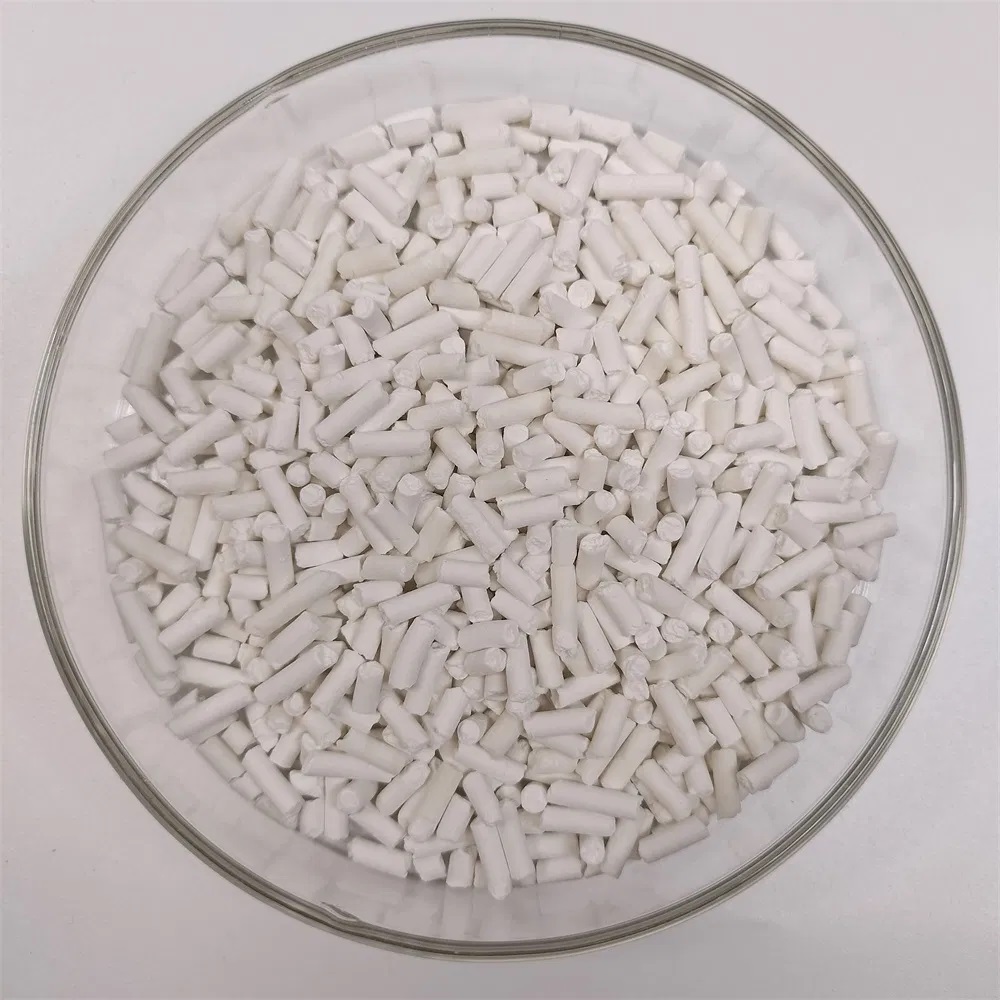

Ca Calcium Pellets Granules Evaporation Materials

- High Reactivity: Calcium easily reacts with oxygen and nitrogen, making it ideal for certain oxidation-controlled processes.

- High Purity: Available in high-purity forms (≥ 99.9%), ensuring minimal impurities in thin film coatings.

- Good Evaporation Characteristics: Calcium has a relatively low evaporation temperature (842°C), allowing efficient deposition in vacuum environments.

- Versatile Applications: Calcium can be used for coatings that require lightweight, high-performance films in various high-tech applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Calcium |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Calcium (Ca) pellets are widely used in vacuum evaporation processes for producing thin films with unique optical and electronic properties. As a highly reactive alkaline earth metal, calcium is often applied in various advanced industries, including semiconductor manufacturing, optics, and photovoltaics. Its use in evaporation helps deposit high-purity, thin layers on substrates for functional coatings.

Key Applications:

- Optical Coatings: Used in reflective and anti-reflective coatings, enhancing the performance of optical components such as lenses and mirrors.

- Semiconductors: Applied in thin films for electronic devices, ensuring high conductivity and specialized electronic properties.

- Photovoltaic Cells: Employed in the production of solar panels to improve the efficiency of photovoltaic cells.

- Protective Coatings: Useful in creating protective coatings on various materials due to its ability to form stable compounds with oxygen and other elements.

- Research & Development: Utilized in R&D for the creation of experimental materials and thin film structures.

Features:

- High Reactivity: Calcium easily reacts with oxygen and nitrogen, making it ideal for certain oxidation-controlled processes.

- High Purity: Available in high-purity forms (≥ 99.9%), ensuring minimal impurities in thin film coatings.

- Good Evaporation Characteristics: Calcium has a relatively low evaporation temperature (842°C), allowing efficient deposition in vacuum environments.

- Versatile Applications: Calcium can be used for coatings that require lightweight, high-performance films in various high-tech applications.

Specifications:

- Material: Calcium (Ca)

- Purity Level: ≥ 99.9% (custom purities available)

- Shape: Pellets, optimized for uniform evaporation

- Size: Typically available in sizes ranging from 1mm to 10mm

- Applications: Thin film deposition, optical coatings, semiconductors, photovoltaics

- Melting Point: 842°C

- Density: 1.55 g/cm³

Tinsan Materials offers high-purity Calcium (Ca) Pellets for evaporation, perfect for thin film deposition, optical coatings, semiconductors, and photovoltaic applications. Custom sizes and purities available.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.