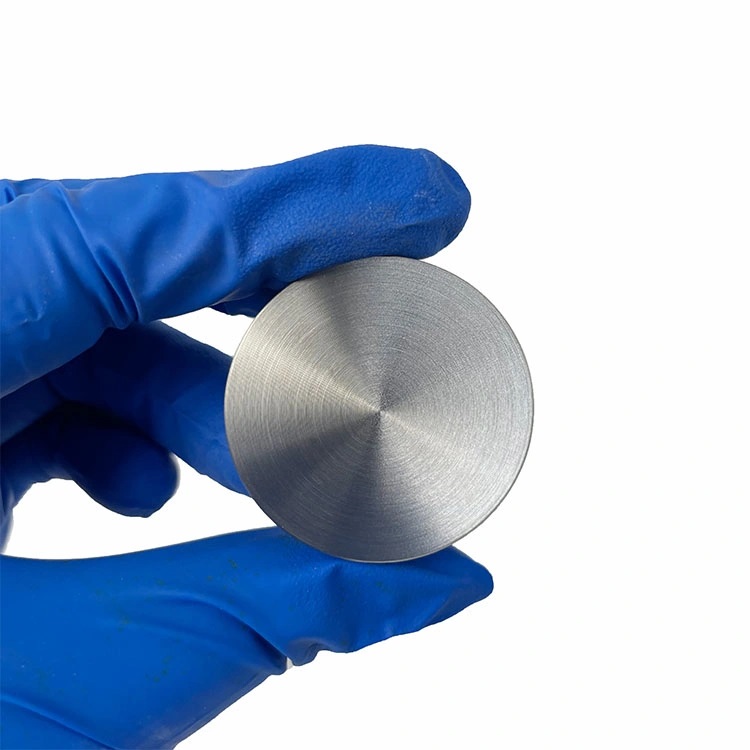

Ce Cerium Sputtering Target

- Purity: Available at 99.9% or higher purity to ensure optimal film quality and performance.

- Oxidation-Reduction Properties: Cerium’s ability to switch between oxidation states (Ce³⁺ and Ce⁴⁺) makes it ideal for catalytic and energy applications.

- Customizable Size and Shape: Cerium sputtering targets are available in various forms such as discs, plates, and cylinders to suit different deposition systems.

- Thermal Stability: Cerium films offer high thermal stability, making them suitable for high-temperature applications like fuel cells and catalytic converters.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Cerium (Ce) |

| Purity | 99.9% – 99.999% / 3N 3N5 4N 4N5 5N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Cerium (Ce) sputtering targets are utilized in physical vapor deposition (PVD) processes to create thin films with unique chemical, optical, and catalytic properties. Cerium, a rare earth metal, is well-known for its oxidation-reduction capabilities and is widely used in advanced materials for energy, electronics, and environmental applications.

Key Applications:

- Catalysts: Cerium oxide (CeO₂) films are used in catalytic converters for automotive emissions control, as well as in industrial processes due to their ability to promote oxidation reactions.

- Optical Coatings: Cerium films are employed in optical applications such as UV-blocking filters, glass polishing, and enhancing the performance of UV and visible light sensors.

- Fuel Cells: Cerium-based thin films play a role in solid oxide fuel cells (SOFCs), improving ion conductivity and thermal stability.

- Semiconductors: Cerium sputtering targets are used in semiconductor fabrication for applications requiring dielectric properties, particularly in microelectronics and thin-film transistors.

- Protective Coatings: Cerium thin films provide protective and anti-corrosion coatings in aerospace, marine, and other harsh-environment applications.

Features of Cerium Sputtering Targets:

- Purity: Available at 99.9% or higher purity to ensure optimal film quality and performance.

- Oxidation-Reduction Properties: Cerium’s ability to switch between oxidation states (Ce³⁺ and Ce⁴⁺) makes it ideal for catalytic and energy applications.

- Customizable Size and Shape: Cerium sputtering targets are available in various forms such as discs, plates, and cylinders to suit different deposition systems.

- Thermal Stability: Cerium films offer high thermal stability, making them suitable for high-temperature applications like fuel cells and catalytic converters.

Customization Options:

- Dimensions: Cerium sputtering targets can be customized in diameter, thickness, and shape to meet specific system requirements.

- Purity Levels: High-purity cerium (99.9%+) for precision and performance-driven applications.

- Backing Plates: Optional backing plates for improved durability and ease of mounting during the sputtering process.

Cerium sputtering targets from Tinsan Materials offer high-purity Ce for thin film deposition, catalytic applications, optical coatings, and semiconductors. Custom sizes and shapes available for optimized PVD performance.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.