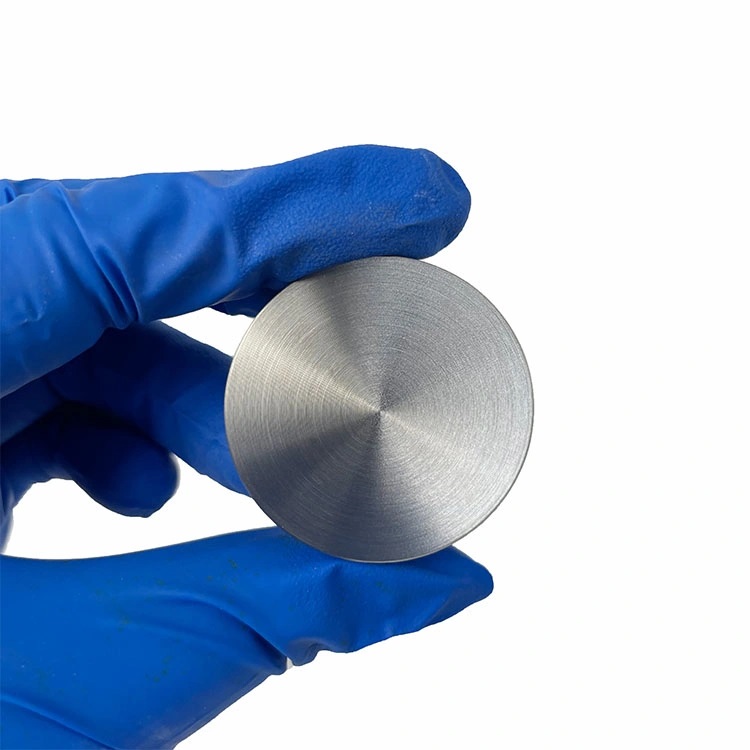

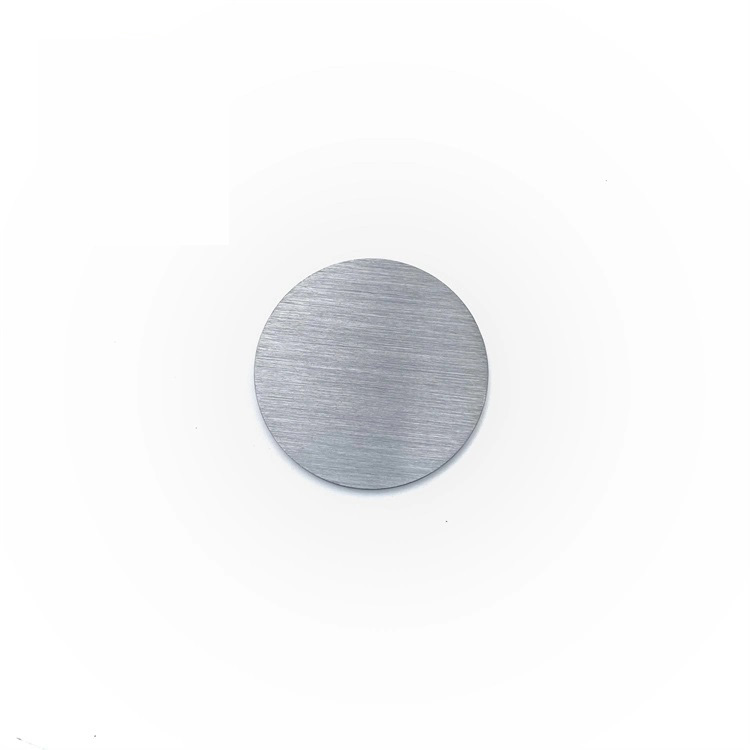

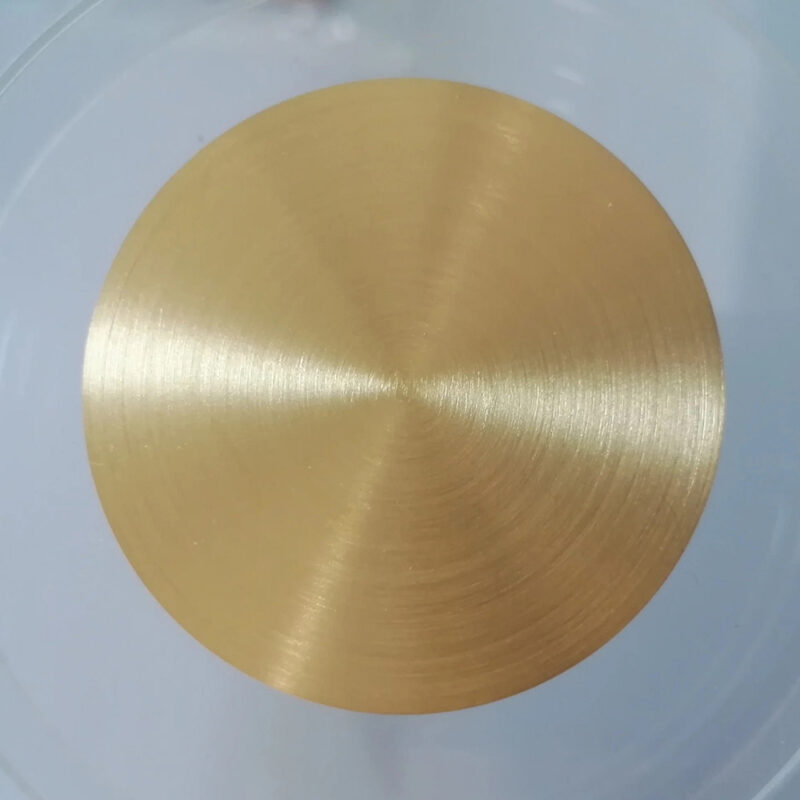

CoCrMo (Cobalt Chromium Molybdenum) Alloy Target

- Biocompatibility: CoCrMo alloys are highly biocompatible, making them ideal for medical implants and devices that come in contact with human tissue and bone.

- Wear Resistance: The addition of molybdenum enhances the alloy’s resistance to wear and fatigue, making CoCrMo thin films durable under mechanical stress and long-term use.

- Corrosion Resistance: Cobalt and chromium provide excellent corrosion resistance, protecting components from damage in harsh environments, including body fluids, chemicals, and marine conditions.

- Mechanical Strength: CoCrMo alloy sputtering targets produce thin films with exceptional mechanical strength, allowing coated components to withstand high loads and stresses.

- High-Temperature Stability: CoCrMo alloys retain their properties at elevated temperatures, making them suitable for applications in aerospace and industrial settings where heat resistance is critical.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Cobalt Chromium Molybdenum |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Cobalt-Chromium-Molybdenum (CoCrMo) alloy sputtering targets are known for their exceptional wear resistance, corrosion resistance, and biocompatibility. These properties make CoCrMo alloys ideal for producing thin films in a variety of demanding applications, particularly in the medical, aerospace, and industrial sectors.

Key Applications:

- Medical Implants: CoCrMo alloy thin films are widely used in medical applications, especially for orthopedic implants, dental implants, and surgical instruments. The alloy’s biocompatibility and resistance to wear and corrosion make it ideal for these applications.

- Aerospace: In the aerospace industry, CoCrMo alloy thin films are used to coat components that must endure extreme mechanical stress, wear, and exposure to harsh environmental conditions, including high temperatures.

- Industrial Tools and Machinery: CoCrMo alloy sputtering targets are used for depositing hard, wear-resistant coatings on industrial tools, such as cutting tools, drills, and machinery components, significantly extending their operational lifespan and improving performance.

- Corrosion-Resistant Coatings: The alloy is commonly applied in environments exposed to moisture, chemicals, or salt, providing excellent corrosion protection for components in marine, automotive, and industrial applications.

- Biomedical Devices: CoCrMo thin films are also used in biomedical devices where high biocompatibility and long-term durability are essential, such as stents and prosthetic devices.

Features of CoCrMo Alloy Sputtering Targets:

- Biocompatibility: CoCrMo alloys are highly biocompatible, making them ideal for medical implants and devices that come in contact with human tissue and bone.

- Wear Resistance: The addition of molybdenum enhances the alloy’s resistance to wear and fatigue, making CoCrMo thin films durable under mechanical stress and long-term use.

- Corrosion Resistance: Cobalt and chromium provide excellent corrosion resistance, protecting components from damage in harsh environments, including body fluids, chemicals, and marine conditions.

- Mechanical Strength: CoCrMo alloy sputtering targets produce thin films with exceptional mechanical strength, allowing coated components to withstand high loads and stresses.

- High-Temperature Stability: CoCrMo alloys retain their properties at elevated temperatures, making them suitable for applications in aerospace and industrial settings where heat resistance is critical.

Customization Options:

- Dimensions: CoCrMo sputtering targets are available in a range of shapes and sizes, including discs, plates, and custom geometries, to accommodate specific deposition systems and application needs.

- Purity Levels: High-purity CoCrMo alloy sputtering targets (up to 99.99%) are available for precision applications in the medical, aerospace, and industrial sectors.

- Composition Adjustments: The ratios of cobalt, chromium, and molybdenum can be customized to optimize properties such as wear resistance, corrosion resistance, or biocompatibility for specific applications.

CoCrMo alloy sputtering targets from Tinsan Materials offer excellent wear resistance, corrosion resistance, and biocompatibility, ideal for medical implants, aerospace, and industrial coatings. Custom sizes and compositions available for optimized thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.