CoO (Cobalt Oxide) Sputtering Target

- Antiferromagnetic Properties: CoO exhibits antiferromagnetic behavior, which is useful in magnetic storage applications and spintronics.

- High Stability: Cobalt Oxide is thermally and chemically stable, making it suitable for applications in harsh environments, including high-temperature energy storage and catalysis.

- Catalytic Activity: CoO’s catalytic properties make it an important material for fuel cells and chemical reactors, especially in energy and environmental applications.

- Semiconductor Characteristics: CoO has semiconducting properties, with applications in optoelectronics, sensors, and energy devices.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | CoO |

| Purity | 99.9% – 99.99999% / 3N 3N5 4N 4N5 5N 5N5 6N 6N5 7N |

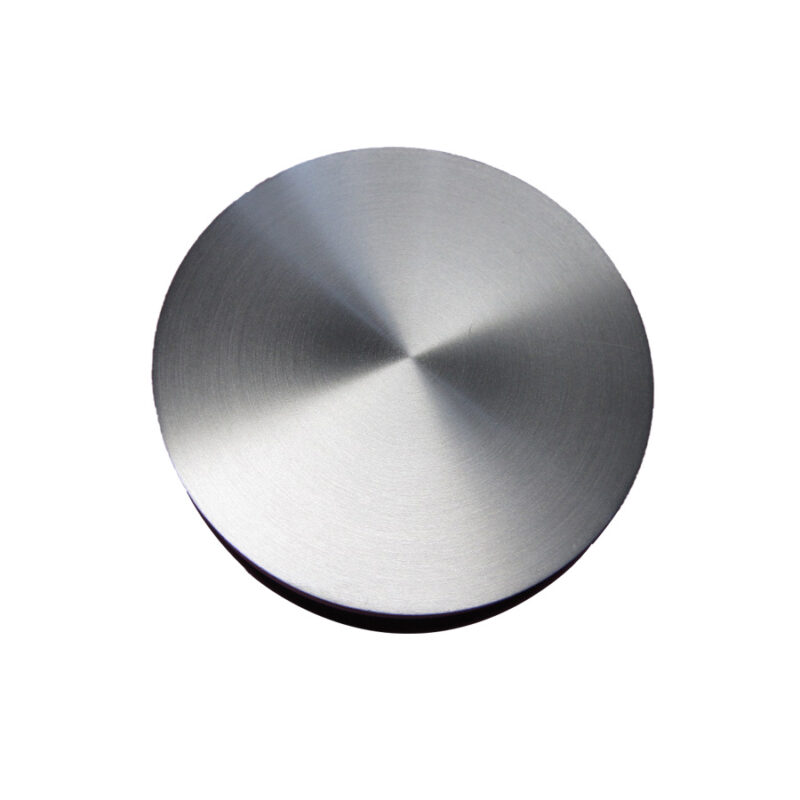

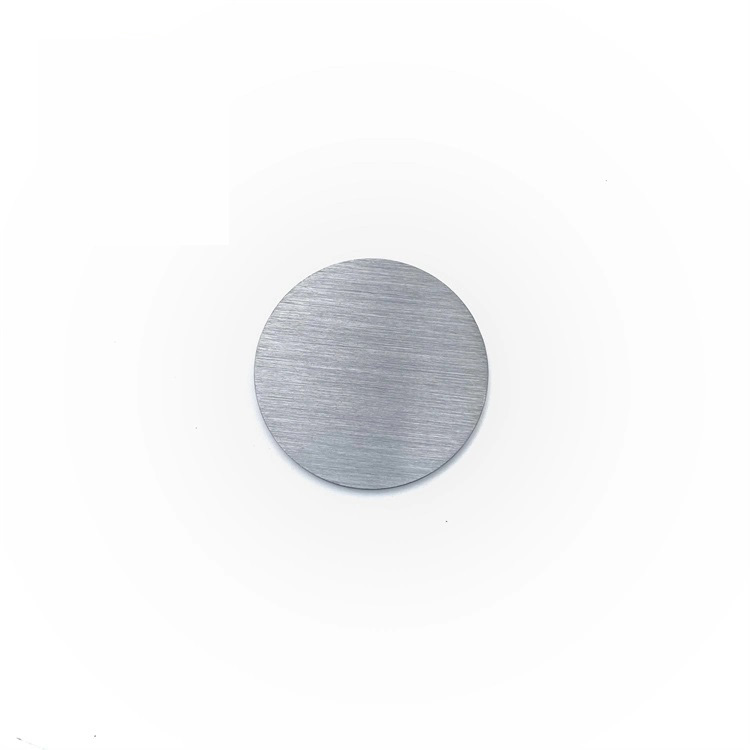

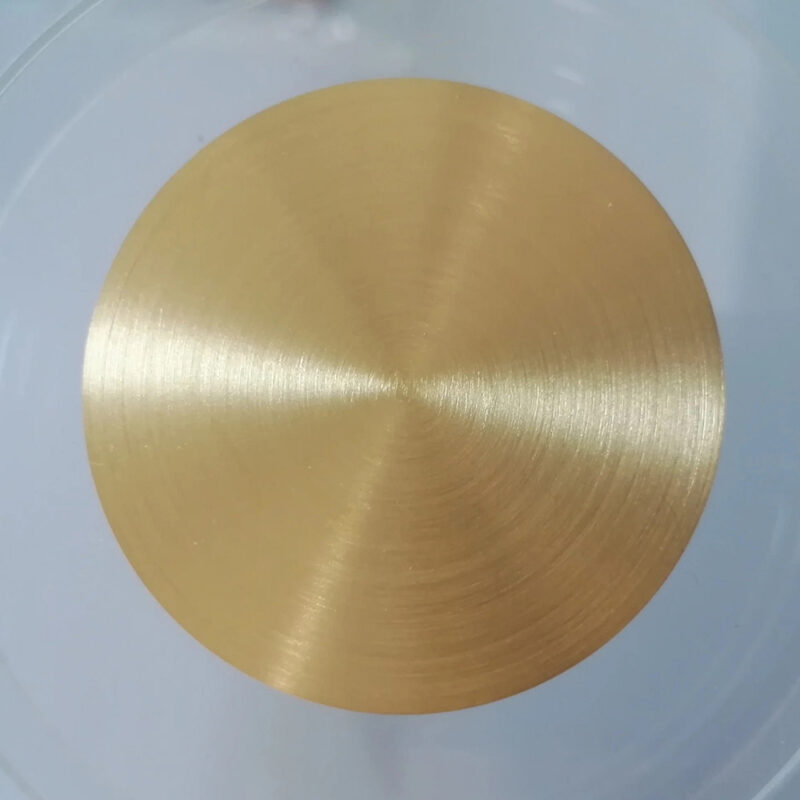

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

CoO (Cobalt Oxide) sputtering targets are widely used in the deposition of thin films for various advanced applications, especially in electronics, energy storage, and catalysis. Cobalt(II) Oxide is a transition metal oxide with excellent magnetic, electronic, and catalytic properties, making it valuable in the production of high-performance materials.

Key Applications:

- Magnetic Storage Media: CoO thin films are used in the production of magnetic storage devices due to their antiferromagnetic properties, which make them valuable in spintronics and magnetic recording applications.

- Energy Storage: CoO is used in thin-film batteries and supercapacitors as an active material for electrodes, providing high energy density and excellent charge-discharge capabilities.

- Catalysis: Cobalt Oxide is utilized as a catalyst in various chemical reactions, including in fuel cells, where CoO thin films enhance the efficiency of oxygen reduction and oxidation processes.

- Sensors: CoO thin films are used in gas sensors due to their sensitivity to changes in gas concentration, making them suitable for detecting gases like CO, NOx, and hydrocarbons.

- Optoelectronics: CoO films can be employed in optoelectronic devices such as photodetectors and thin-film transistors due to their semiconducting properties.

Features of CoO Sputtering Targets:

- Antiferromagnetic Properties: CoO exhibits antiferromagnetic behavior, which is useful in magnetic storage applications and spintronics.

- High Stability: Cobalt Oxide is thermally and chemically stable, making it suitable for applications in harsh environments, including high-temperature energy storage and catalysis.

- Catalytic Activity: CoO’s catalytic properties make it an important material for fuel cells and chemical reactors, especially in energy and environmental applications.

- Semiconductor Characteristics: CoO has semiconducting properties, with applications in optoelectronics, sensors, and energy devices.

Customization Options:

- Dimensions: CoO sputtering targets are available in a variety of sizes and shapes, such as discs, plates, and custom geometries, depending on the needs of the sputtering system.

- Purity: High-purity CoO sputtering targets (up to 99.999%) are available for applications requiring minimal contamination and high-quality thin films.

- Doping: Cobalt Oxide can be doped with other elements to modify its electrical, optical, or magnetic properties for specialized applications.

CoO (Cobalt Oxide) sputtering targets from Tinsan Materials are ideal for applications in magnetic storage, energy storage, catalysis, and sensors. High-purity and customizable sizes available for advanced thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.