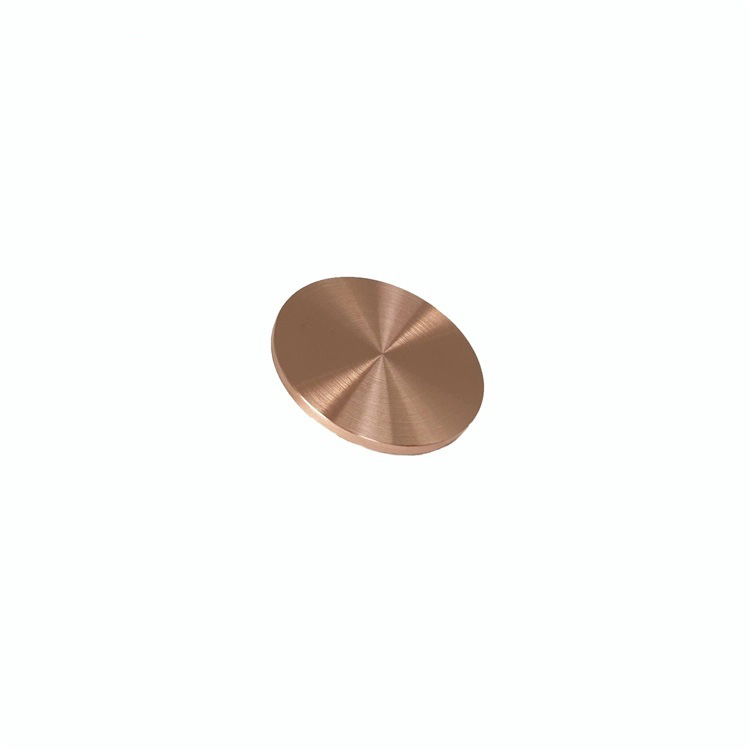

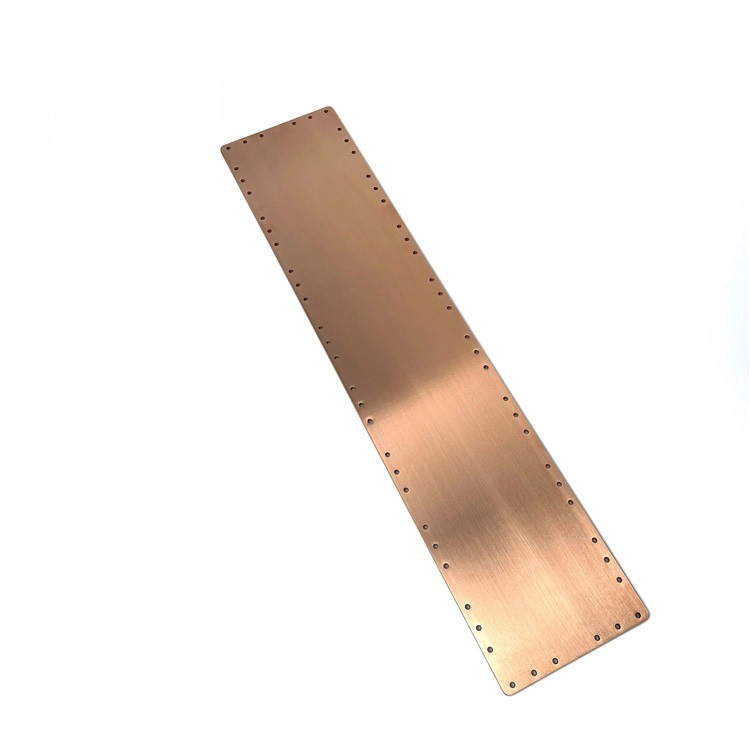

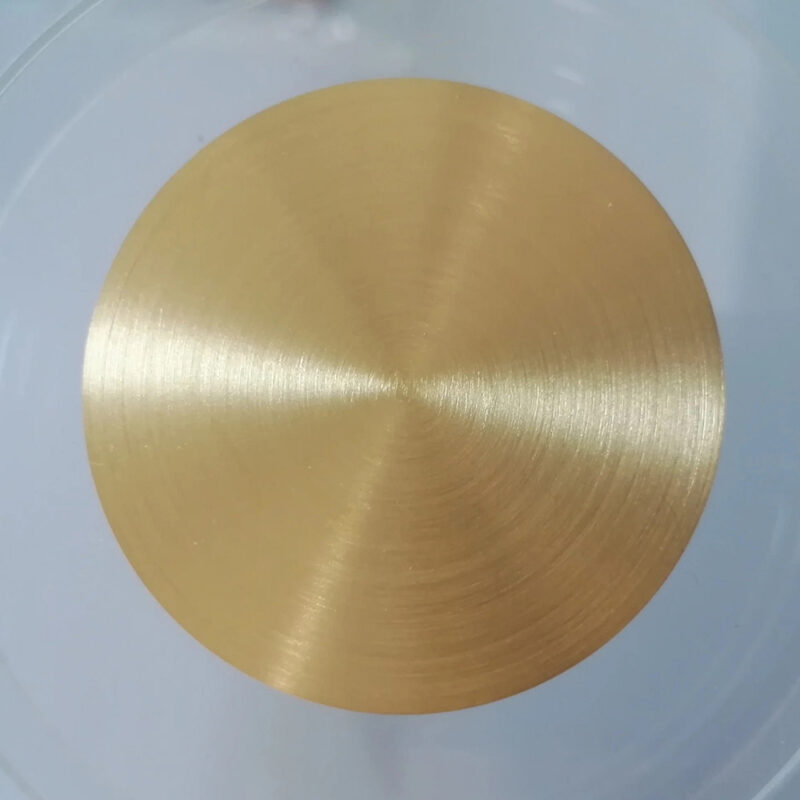

Cu Copper Sputtering Target

Copper (Cu) is highly valued for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it a key material in a variety of industries, including electronics, semiconductors, and energy. Copper (Cu) sputtering targets are essential for industries that require highly conductive, thermally efficient, and corrosion-resistant coatings, making them indispensable in electronics, semiconductors, energy, and decorative applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Cuprum (Cu) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pc |

| Supply Ability | 1000pcs per month |

| Lead time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Copper (Cu) is highly valued for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it a key material in a variety of industries, including electronics, semiconductors, and energy. Copper (Cu) sputtering targets are essential for industries that require highly conductive, thermally efficient, and corrosion-resistant coatings, making them indispensable in electronics, semiconductors, energy, and decorative applications.

Key Features:

- Purity: Copper sputtering targets typically come in high purity levels, often 99.99% (4N) or higher, ensuring the deposition of high-quality, consistent films.

- Shapes and Sizes: These targets are available in various forms, such as discs, plates, and custom shapes, to suit different sputtering systems and application needs.

Applications:

- Electronics: Copper is widely used in the production of conductive layers in semiconductor devices, printed circuit boards (PCBs), and other electronic components due to its outstanding electrical conductivity.

- Interconnects: In integrated circuits (ICs), copper is used to create interconnects between different layers, replacing aluminum in many applications due to its superior conductivity and electromigration resistance.

- Energy: Copper coatings are employed in solar cells and other energy-related applications, where its high thermal and electrical conductivity enhance efficiency.

- Decorative Coatings: Copper is also used in decorative applications, providing a bright, reflective finish that is both durable and aesthetically pleasing.

Customization Options:

- Thickness: The thickness of the copper coating can be precisely controlled during the sputtering process, allowing for tailored solutions to meet specific application requirements.

- Alloys: Copper sputtering targets can also be produced as alloys, such as Cu-Zn (brass) or Cu-Ni, depending on the desired properties of the thin film.

- Backing Plates: Copper targets can be bonded to backing plates made from materials like molybdenum or aluminum to improve thermal conductivity and mechanical stability during the sputtering process.

Copper (Cu) sputtering targets are essential for industries that require highly conductive, thermally efficient, and corrosion-resistant coatings, making them indispensable in electronics, semiconductors, energy, and decorative applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.