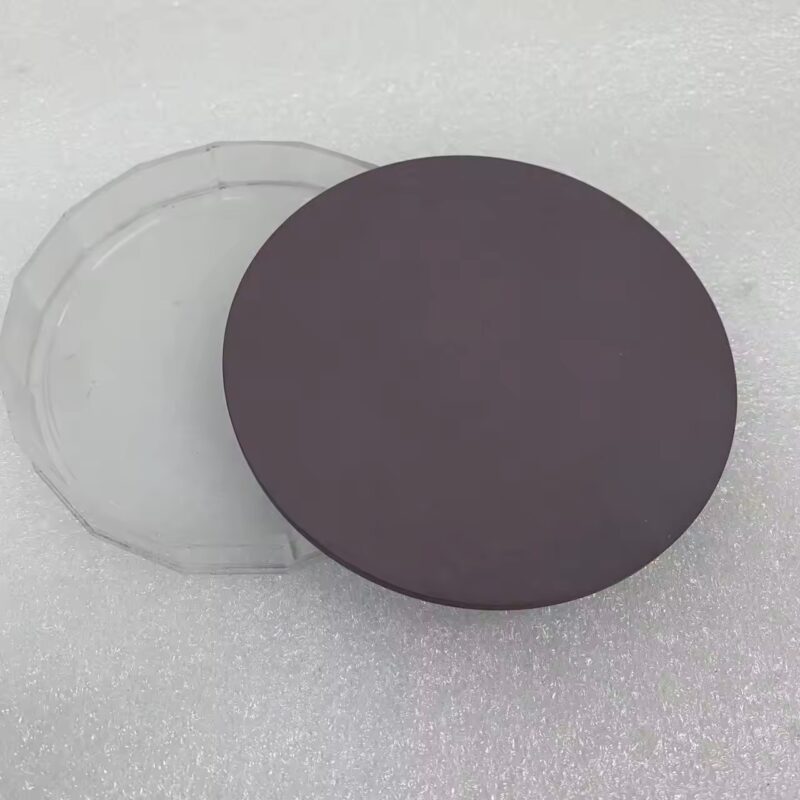

Cu Copper Crucible

- Excellent thermal conductivity for rapid and even heating

- Suitable for metals with lower melting points and temperature-sensitive processes

- Versatile shapes and customizable sizes available for diverse applications

- High electrical conductivity for electrochemical processes

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Copper crucibles are specialized containers made from high-purity copper, ideal for applications requiring efficient heat conductivity and controlled high-temperature processes. These crucibles are commonly used in metallurgical, chemical, and laboratory settings due to their ability to conduct heat rapidly and evenly.

Properties and Performance:

- Excellent Thermal Conductivity: Copper has one of the highest thermal conductivities of any metal, allowing it to heat up and cool down quickly, which is essential for precise temperature control in certain processes.

- Moderate Melting Point: Copper crucibles can withstand temperatures up to approximately 1085°C (1985°F), which is suitable for melting and processing metals with relatively low melting points, like gold, silver, and various alloys.

- Electrical Conductivity: Copper crucibles are excellent electrical conductors, which can be beneficial in applications that require both thermal and electrical energy, such as in certain electrochemical processes.

- Corrosion Resistance: Copper has moderate corrosion resistance but may require additional treatments or coatings when used with highly reactive substances or in oxidative environments.

- Malleability and Ductility: Copper’s malleability allows crucibles to be manufactured in various shapes and sizes, accommodating different laboratory and industrial needs.

- High Purity Grades: High-purity copper crucibles are available for applications where contamination must be minimized, such as in high-precision metal and alloy processing.

Applications:

- Metallurgy: Copper crucibles are widely used in metallurgy for melting and alloying metals like gold, silver, and copper-based alloys, as copper’s thermal conductivity allows for uniform heating and efficient melting.

- Chemical Processing: Due to copper’s moderate corrosion resistance, copper crucibles are used in specific chemical reactions and processes, especially where rapid heating is needed.

- Glass and Ceramics Production: Copper crucibles are suitable for use in certain types of glass and ceramics production, particularly for processing materials that require controlled, even heat distribution.

- Laboratory Testing: In analytical chemistry and materials science, copper crucibles are used for melting point analysis, high-temperature reactions, and thermal treatment of samples with low melting points.

- Electrochemical Applications: Due to copper’s high electrical and thermal conductivity, copper crucibles are also used in electrochemical processes where heating and electrical conductivity are required.

Types of Copper Crucibles:

- Pure Copper Crucibles: These are ideal for high-purity applications, often used in laboratories for metals research and materials testing.

- Copper Alloy Crucibles: Certain copper alloys are also used for crucibles to provide enhanced mechanical strength or specific thermal properties, depending on the application.

- Coated Copper Crucibles: Sometimes copper crucibles are coated with other materials to enhance corrosion resistance when used with reactive substances.

Advantages of Copper Crucibles:

- Excellent thermal conductivity for rapid and even heating

- Suitable for metals with lower melting points and temperature-sensitive processes

- Versatile shapes and customizable sizes available for diverse applications

- High electrical conductivity for electrochemical processes

In summary, copper crucibles are essential tools in industries that require precise temperature control and rapid heat conduction, making them invaluable in metallurgy, chemical processing, laboratory applications, and more.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.