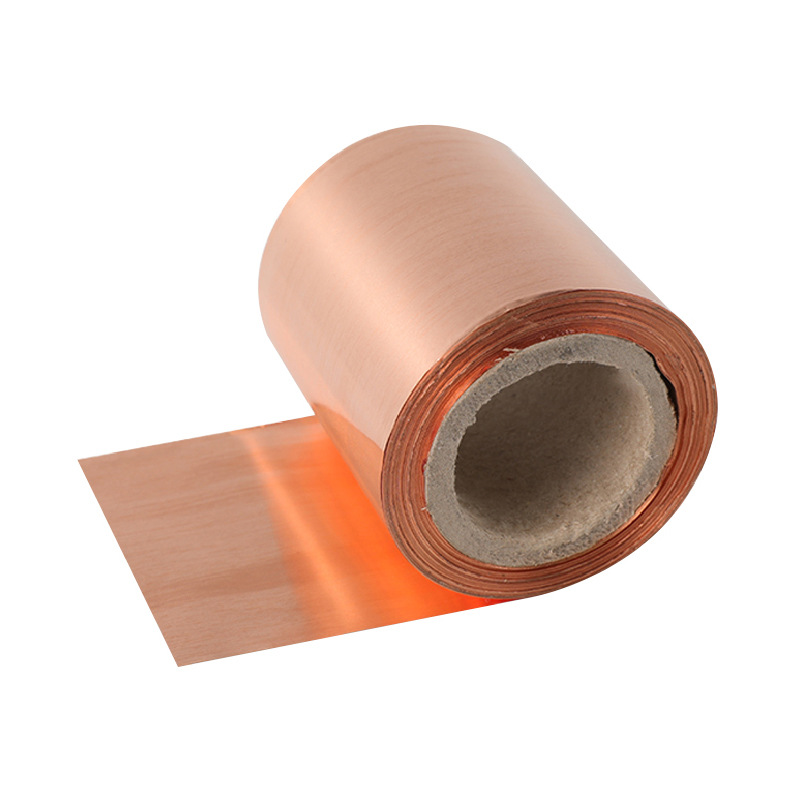

Cu Copper Foil

- High Electrical Conductivity: Copper foil is known for its excellent electrical conductivity, making it ideal for use in electrical and electronic applications. It allows the efficient flow of electrical current with minimal resistance, which is crucial in devices like circuit boards, power systems, and transformers.

- Thermal Conductivity: Copper is one of the best materials for heat conduction. Copper foil efficiently dissipates heat, making it essential in applications such as heat sinks, thermal management, and cooling systems.

- Corrosion Resistance: Copper foil naturally forms a protective oxide layer on its surface, which helps resist corrosion, especially in environments exposed to moisture or chemicals. This makes copper foil durable and suitable for a range of industrial applications.

- Malleability and Ductility: Copper foil is highly malleable and can be easily formed into various shapes and sizes without cracking. This flexibility allows for diverse uses in manufacturing, especially for flexible printed circuits and various packaging applications.

- Lightweight: Copper foil is lightweight, making it easy to handle and transport. Despite its lightness, it maintains excellent mechanical strength and durability, making it an attractive option for many industries that require both strength and weight reduction.

- Recyclability: Copper is 100% recyclable without losing its properties. This makes copper foil an environmentally friendly choice, as it can be reused multiple times, reducing waste and supporting sustainable practices.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Copper foil is a thin sheet of copper metal that is widely used in various industrial applications due to its excellent electrical and thermal conductivity, high strength, and corrosion resistance. With its versatility and superior performance, copper foil is a preferred material for electronics, automotive, renewable energy, and other high-tech industries. At Tinsan Materials, we provide high-quality copper foil tailored to meet specific needs and requirements.

Properties of Copper Foil

- High Electrical Conductivity: Copper foil is known for its excellent electrical conductivity, making it ideal for use in electrical and electronic applications. It allows the efficient flow of electrical current with minimal resistance, which is crucial in devices like circuit boards, power systems, and transformers.

- Thermal Conductivity: Copper is one of the best materials for heat conduction. Copper foil efficiently dissipates heat, making it essential in applications such as heat sinks, thermal management, and cooling systems.

- Corrosion Resistance: Copper foil naturally forms a protective oxide layer on its surface, which helps resist corrosion, especially in environments exposed to moisture or chemicals. This makes copper foil durable and suitable for a range of industrial applications.

- Malleability and Ductility: Copper foil is highly malleable and can be easily formed into various shapes and sizes without cracking. This flexibility allows for diverse uses in manufacturing, especially for flexible printed circuits and various packaging applications.

- Lightweight: Copper foil is lightweight, making it easy to handle and transport. Despite its lightness, it maintains excellent mechanical strength and durability, making it an attractive option for many industries that require both strength and weight reduction.

- Recyclability: Copper is 100% recyclable without losing its properties. This makes copper foil an environmentally friendly choice, as it can be reused multiple times, reducing waste and supporting sustainable practices.

Advantages of Copper Foil

- Superior Conductivity: Copper foil is the preferred material for high-performance electrical and electronic devices due to its superior conductivity. It ensures efficient transmission of signals and energy, contributing to the reliability and longevity of electronic circuits.

- Cost-Effectiveness: Copper is relatively cost-effective compared to other conductive metals, making copper foil an economical solution for various applications, especially in large-scale manufacturing and production of electronic devices.

- Durability and Longevity: The natural corrosion resistance of copper ensures that copper foil remains functional and reliable over time. It offers long-lasting performance, even in harsh environments, reducing the need for frequent replacements.

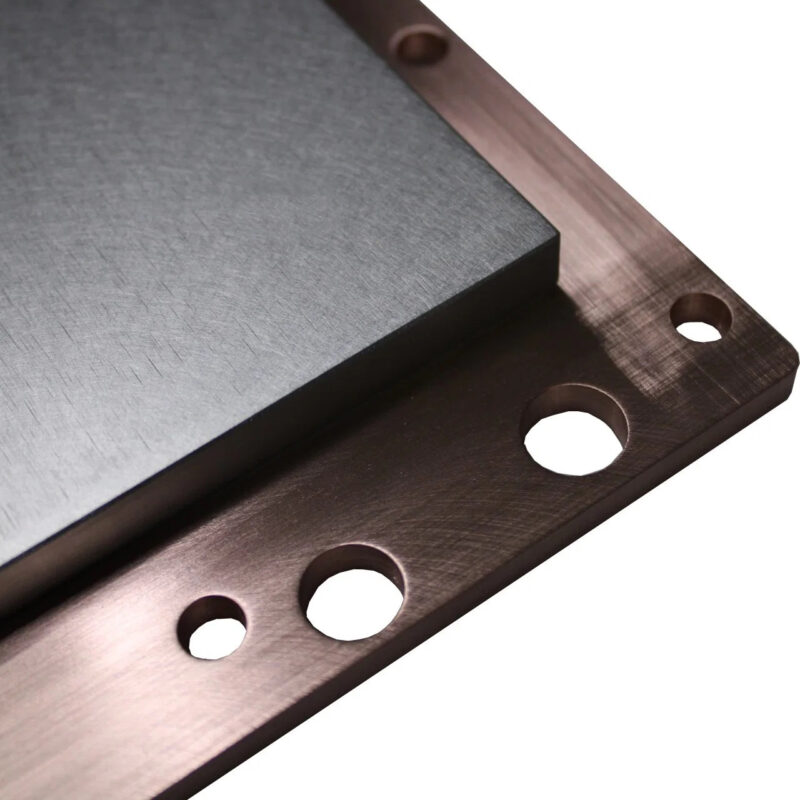

- Customization: Copper foil can be customized in terms of thickness, width, and length to meet the specific requirements of a given application. This flexibility makes it suitable for diverse industrial uses, ranging from flexible printed circuits to automotive components.

- Thermal Management: Copper’s high thermal conductivity makes it an excellent material for managing heat in electronic devices. Copper foil can efficiently conduct heat away from sensitive components, ensuring the longevity and reliability of electronic systems.

- Environmental Benefits: Copper foil’s recyclability and low environmental impact make it a sustainable material choice. It can be reused repeatedly without degradation of its properties, contributing to a circular economy and reducing the ecological footprint.

Applications of Copper Foil

- Printed Circuit Boards (PCBs): Copper foil is extensively used in the production of printed circuit boards (PCBs), which are fundamental components in almost all electronic devices. It forms the conductive traces on the PCB, allowing for the transmission of electrical signals between components.

- Flexible Electronics: In the growing field of flexible electronics, copper foil is used in the production of flexible printed circuits (FPCs), which are essential in smartphones, wearable devices, and flexible displays. Copper’s malleability and conductivity make it ideal for flexible applications.

- Batteries: Copper foil is commonly used as a current collector in lithium-ion and other types of batteries. It helps in the efficient transfer of electrical charge within the battery, enhancing its performance and lifespan.

- Thermal Management: Copper foil is used in heat sinks, heat exchangers, and thermal pads for electronics, automotive, and aerospace applications. Its superior thermal conductivity ensures effective heat dissipation, preventing overheating in high-performance devices.

- Solar Energy: Copper foil plays a critical role in solar energy technology, particularly in photovoltaic cells. It is used to form the electrical contacts on solar panels, enabling the efficient conversion of sunlight into electricity.

- Automotive Industry: In the automotive sector, copper foil is used in applications such as electric vehicle (EV) batteries, electrical systems, and heat management systems. Its excellent conductivity and thermal properties make it ideal for automotive applications.

- Telecommunications: Copper foil is used in telecommunications for the manufacture of cables, connectors, and other critical components. It ensures reliable signal transmission and is crucial for the performance of high-speed communication systems.

- Electromagnetic Shielding: Copper foil is also used for electromagnetic shielding in electronic devices, ensuring that sensitive equipment is protected from external electromagnetic interference (EMI) that could degrade its performance.

Customization and Manufacturing of Copper Foil

At Tinsan Materials, we offer copper foil in a variety of grades, thicknesses, and widths to meet the specific needs of our customers. Whether you need ultra-thin foil for flexible circuits or thicker foil for heat dissipation applications, we can provide tailored solutions. Our manufacturing process includes continuous quality control to ensure consistent material properties, such as thickness tolerance and surface smoothness, ensuring that the final product meets your exact requirements.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.