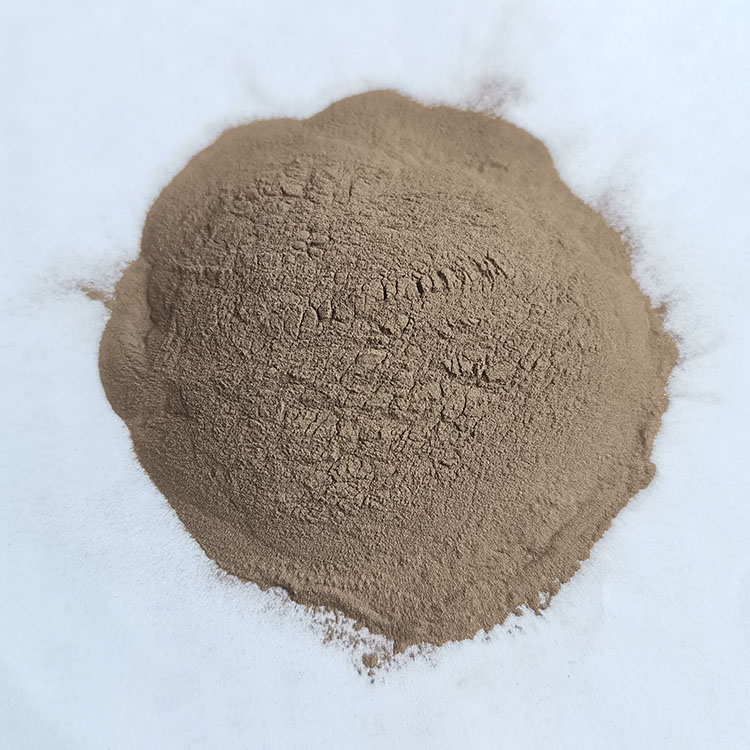

CuFe (Copper Iron) Alloy Powder for 3D Printing

- High Electrical Conductivity: Retains copper’s excellent conductive properties.

- Mechanical Strength: Enhanced by the inclusion of iron, making it suitable for robust applications.

- Customizable Composition: Various Cu-Fe ratios tailored to specific industrial needs.

- Corrosion Resistance: Provides protection against oxidation and wear.

- Uniform Particle Size: Ensures consistency in manufacturing processes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Iron Copper (FeCu) |

| Purity | 99% – 99.99% / 2N 2N5 3N 3N5 4N |

| Shape | powder / nanopowder / nanoparticles |

| Size | can be customized (contact us) |

| Package | bottle / bag or customer’s request |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Copper-Iron Alloy Powder (Cu-Fe) is a versatile metal powder combining the electrical conductivity of copper with the strength and durability of iron. Tinsan Materials offers high-quality Cu-Fe alloy powders with customizable compositions, particle sizes, and purity levels, catering to diverse industrial needs such as additive manufacturing, powder metallurgy, and electronic applications.

Key Features

- High Electrical Conductivity: Retains copper’s excellent conductive properties.

- Mechanical Strength: Enhanced by the inclusion of iron, making it suitable for robust applications.

- Customizable Composition: Various Cu-Fe ratios tailored to specific industrial needs.

- Corrosion Resistance: Provides protection against oxidation and wear.

- Uniform Particle Size: Ensures consistency in manufacturing processes.

Specifications

- Chemical Composition: Copper (Cu) and Iron (Fe) in customizable ratios.

- Purity: ≥ 99% (combined metals).

- Particle Size: Nano to micron scale, customizable for specific applications.

- Density: Depends on the Cu-Fe ratio; typically ~8.9 g/cm³ for Cu-dominant alloys.

- Melting Point: Varies based on composition (~1,080°C for pure copper and ~1,538°C for pure iron).

- Packaging: Moisture-proof, vacuum-sealed containers for long-term stability.

Applications

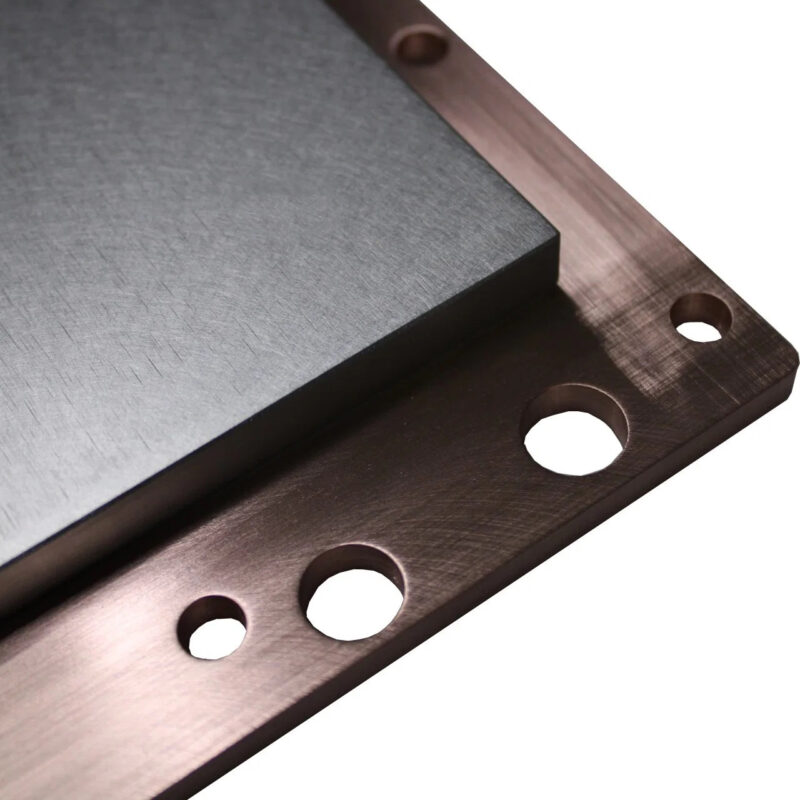

- Additive Manufacturing: Used in 3D printing for creating conductive and durable components.

- Powder Metallurgy: Ideal for producing wear-resistant and high-strength parts.

- Electrical Components: Suitable for making connectors, switches, and other conductive parts.

- Thermal Management: Utilized in heat sinks and thermal conductive applications.

- R&D: Supports the development of advanced alloy systems and new materials.

Tinsan Materials’ Copper-Iron Alloy Powder combines conductivity with strength, making it ideal for diverse applications such as additive manufacturing, powder metallurgy, and electronic component production. Customizable compositions and particle sizes ensure compatibility with various industrial needs.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.