CuO (Copper(II) Oxide) Pellets Granules Evaporation Materials

- Semiconducting Properties: CuO is a p-type semiconductor, making it valuable for use in electronic devices.

- High Absorptivity: CuO has excellent light absorption properties, which is beneficial for solar energy applications.

- Chemical Stability: CuO coatings are chemically stable and can withstand environmental exposure, enhancing the durability of the films.

- Good Adhesion: CuO thin films demonstrate strong adhesion to various substrates, including glass, silicon, and metals.

- Easy Processing: CuO can be easily deposited using standard PVD techniques like thermal evaporation or electron-beam evaporation.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | CuO |

| Purity | 99.9% – 99.999% / 3N 3N5 4N 4N5 5N |

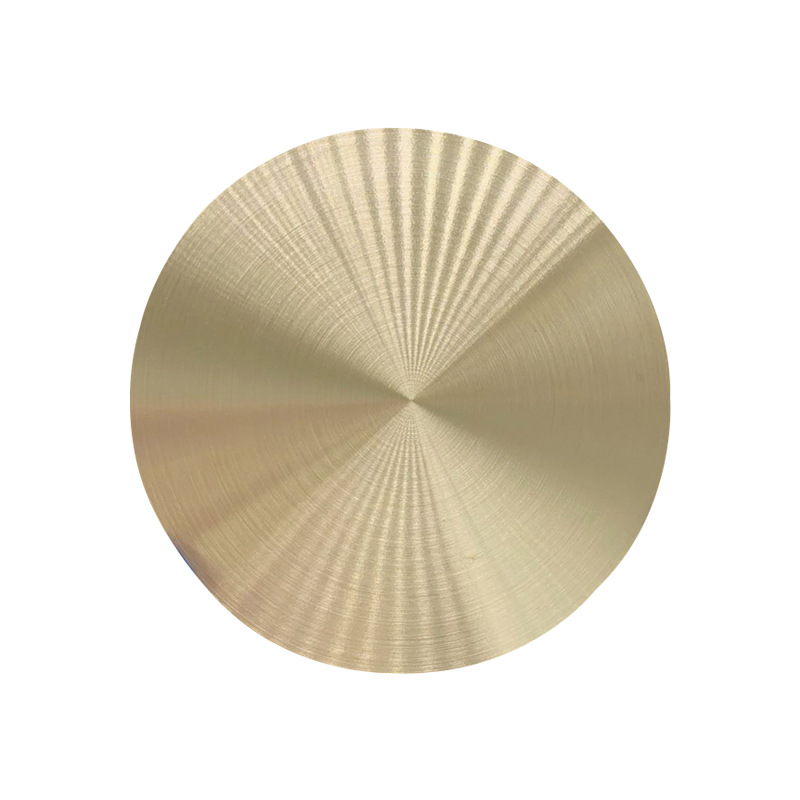

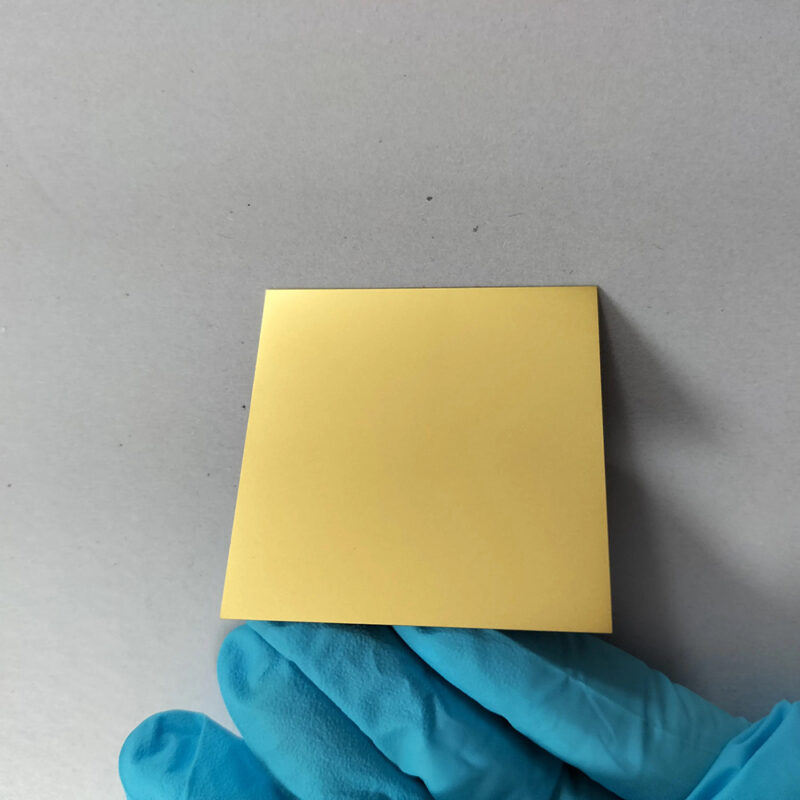

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Copper(II) Oxide (CuO) is a widely used ceramic material in the thin-film deposition industry. CuO pellets are employed in evaporation techniques such as thermal evaporation and electron-beam evaporation for depositing thin films of copper oxide. These films exhibit semiconducting properties and are commonly used in electronics, solar cells, sensors, and optical coatings.

Key Applications:

- Solar Cells: CuO thin films are used in photovoltaic devices, particularly in the fabrication of p-type semiconductors in solar cells.

- Thin-Film Transistors (TFTs): CuO coatings are used in the electronics industry for the development of thin-film transistors.

- Gas Sensors: CuO thin films provide a base for gas sensors, particularly for detecting gases like hydrogen and carbon monoxide.

- Optical Coatings: CuO can be applied in optical components for anti-reflective and other functional coatings.

- Catalysis: CuO thin films are also used in catalytic applications due to their reactivity and surface characteristics.

Features:

- Semiconducting Properties: CuO is a p-type semiconductor, making it valuable for use in electronic devices.

- High Absorptivity: CuO has excellent light absorption properties, which is beneficial for solar energy applications.

- Chemical Stability: CuO coatings are chemically stable and can withstand environmental exposure, enhancing the durability of the films.

- Good Adhesion: CuO thin films demonstrate strong adhesion to various substrates, including glass, silicon, and metals.

- Easy Processing: CuO can be easily deposited using standard PVD techniques like thermal evaporation or electron-beam evaporation.

Specifications:

- Material: Copper(II) Oxide (CuO)

- Purity: ≥ 99.9%

- Shape: Pellets

- Size: Available in custom sizes, typically ranging from 1mm to 6mm in diameter

- Melting Point: ~1201°C

- Density: 6.31 g/cm³

- Deposition Methods: Suitable for thermal evaporation, electron-beam evaporation, and other PVD processes

- Applications: Solar cells, gas sensors, thin-film transistors, optical coatings, catalysis

Tinsan Materials offers high-purity CuO (Copper(II) Oxide) Pellets for thin-film deposition via thermal and electron-beam evaporation. Ideal for solar cells, gas sensors, and optical coatings. Available in various sizes for PVD processes.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.