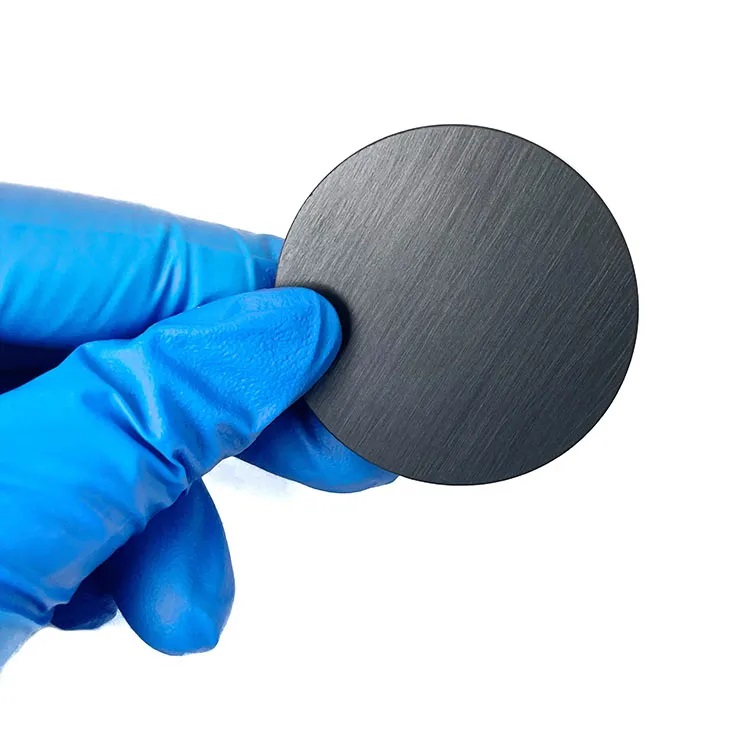

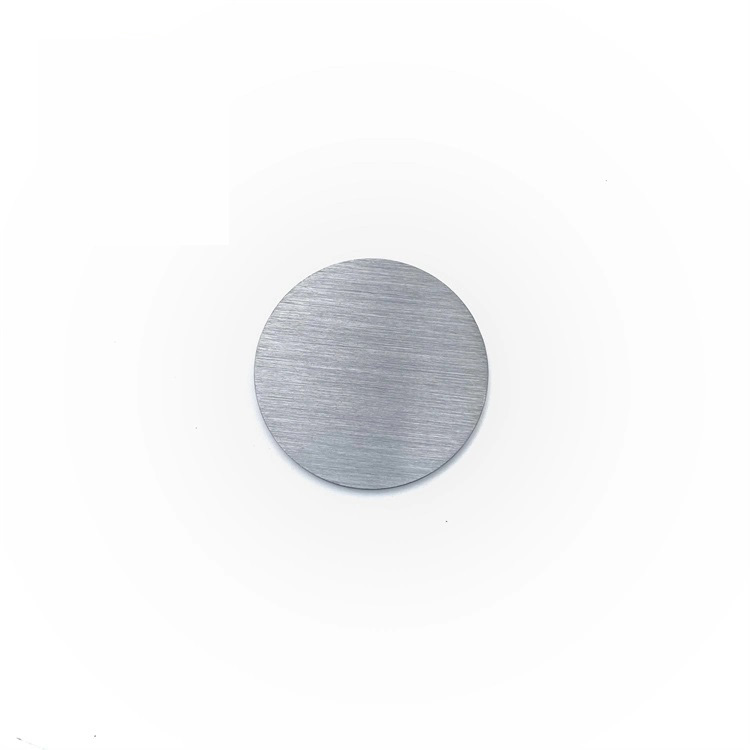

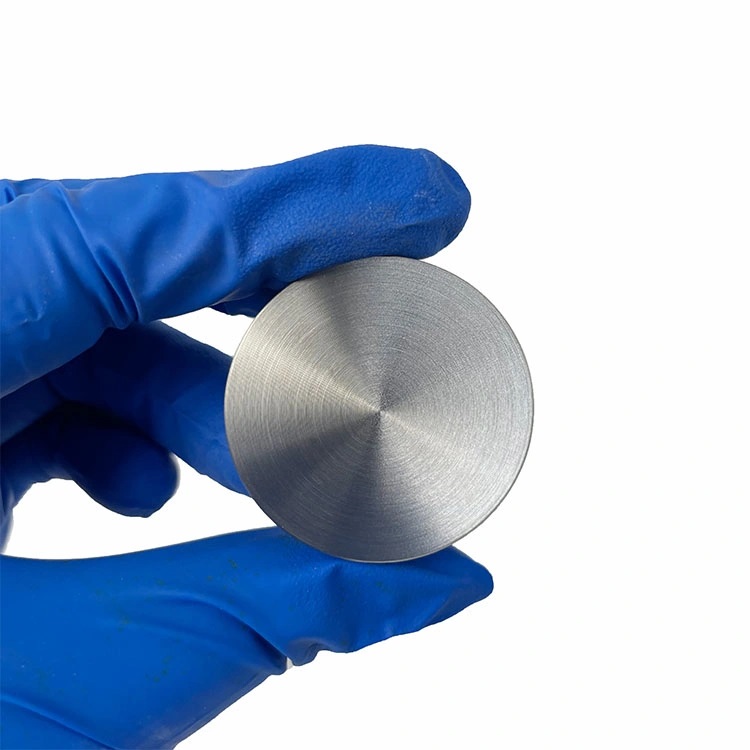

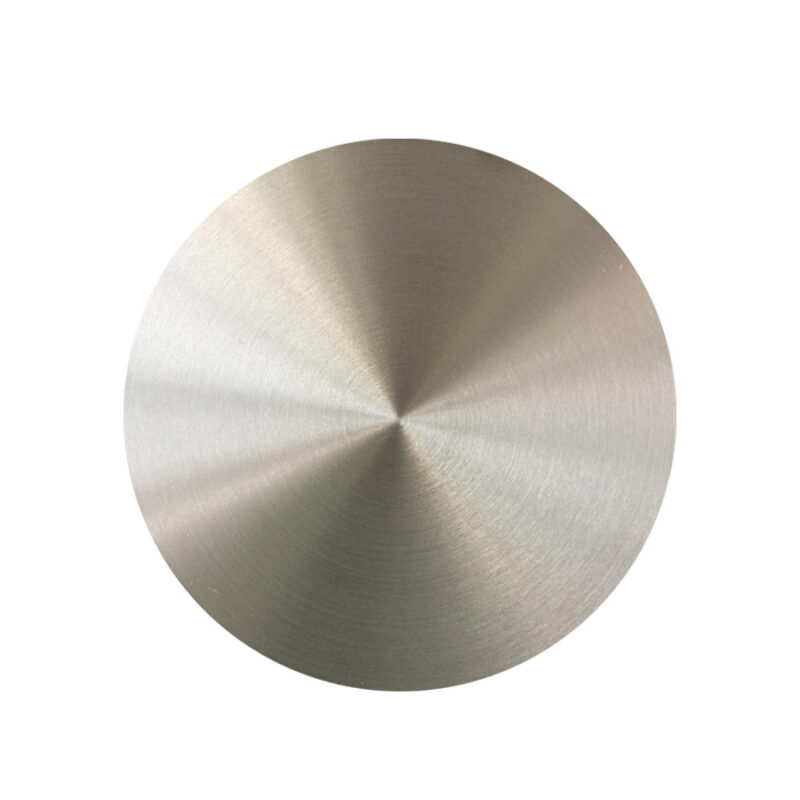

CuS (Copper Sulfide) Sputtering Target

- Semiconductor Properties: CuS is a p-type semiconductor, making it suitable for applications in photovoltaics and semiconductor devices.

- High Absorption: Copper Sulfide has strong light absorption characteristics, especially in the visible spectrum, making it ideal for solar energy applications.

- Customizable: CuS sputtering targets can be customized in terms of size, purity, and bonding options to meet specific deposition requirements.

- High Chemical Stability: CuS is chemically stable, which ensures the longevity and durability of the deposited thin films.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | CuS |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Copper Sulfide (CuS) sputtering targets are widely used in thin-film deposition for applications in photovoltaics, semiconductors, sensors, and optical coatings. CuS is a p-type semiconductor material known for its electrical and optical properties, making it suitable for various advanced technologies.

Key Applications:

- Photovoltaics: CuS is utilized in solar cell manufacturing, particularly in thin-film solar technologies. Its p-type semiconductor behavior makes it an ideal absorber layer in solar cells.

- Semiconductor Devices: CuS thin films are used in electronic devices where p-type semiconducting materials are required, contributing to improved efficiency in various semiconductor applications.

- Optical and Infrared Coatings: CuS thin films have good optical properties and can be used for anti-reflective coatings and infrared (IR) detection systems.

- Gas Sensors: Due to its sensitivity to gases such as hydrogen sulfide (H₂S), CuS thin films are employed in gas-sensing devices, helping to detect and measure gas concentrations.

- Energy Storage Devices: CuS materials are also explored in the production of energy storage devices such as batteries and supercapacitors due to their electrochemical properties.

Features of CuS Sputtering Targets:

- Semiconductor Properties: CuS is a p-type semiconductor, making it suitable for applications in photovoltaics and semiconductor devices.

- High Absorption: Copper Sulfide has strong light absorption characteristics, especially in the visible spectrum, making it ideal for solar energy applications.

- Customizable: CuS sputtering targets can be customized in terms of size, purity, and bonding options to meet specific deposition requirements.

- High Chemical Stability: CuS is chemically stable, which ensures the longevity and durability of the deposited thin films.

Customization Options:

- Target Sizes: CuS sputtering targets are available in a range of shapes and sizes, including round and rectangular forms, tailored to fit different sputtering systems.

- Purity Levels: Targets can be manufactured with high purity levels, up to 99.99%, ensuring high-quality thin films for sensitive applications like photovoltaics.

- Bonding Services: CuS targets can be bonded to backing plates to ensure optimal thermal conductivity during the sputtering process, reducing the risk of cracking or damage.

CuS (Copper Sulfide) sputtering targets from Tinsan Materials offer high-performance thin films for photovoltaics, semiconductors, and gas sensors. With excellent p-type semiconductor properties, strong light absorption, and customizable target sizes, CuS targets are ideal for solar cells, IR coatings, and advanced energy storage applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.