Fe3P (Iron Phosphide) Pellets Granules Evaporation Materials

- High purity (≥99.9%).

- Exceptional magnetic and chemical stability.

- Uniform pellet size for precise and consistent applications.

- Customizable sizes and specifications.

- Excellent thermal resistance and mechanical stability.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Iron Phosphide (Fe₃P) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Iron Phosphide (Fe₃P) Pellets are high-purity materials commonly used in advanced industrial applications such as thin-film deposition, phosphor materials, and metallurgical processes. Known for their excellent magnetic and chemical properties, these pellets are an essential component in semiconductor, photovoltaic, and catalyst industries. Their consistent composition and high purity make them suitable for both industrial production and academic research.

Key Features

- High purity (≥99.9%).

- Exceptional magnetic and chemical stability.

- Uniform pellet size for precise and consistent applications.

- Customizable sizes and specifications.

- Excellent thermal resistance and mechanical stability.

Technical Specifications

① Chemical Composition

- Iron Phosphide (Fe₃P) Content: ≥99.9%.

- Trace Impurities: Available upon request.

② Physical Properties

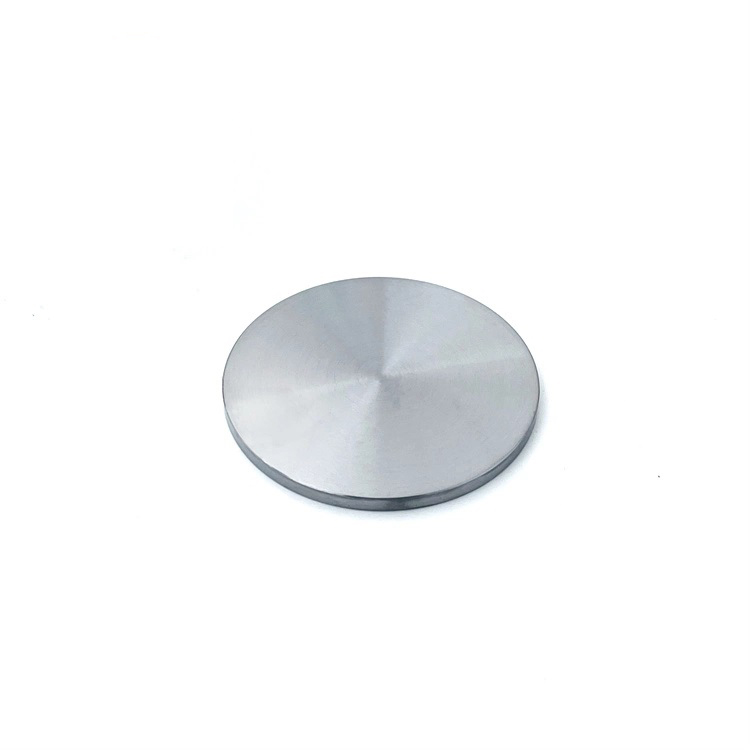

- Appearance: Metallic gray pellets.

- Density: ~6.5 g/cm³.

- Melting Point: ~1100°C.

③ Pellet Size

- Standard Sizes: 1-3 mm, 3-5 mm.

- Custom sizes available to meet specific requirements.

Applications

- Thin-Film Deposition: Ideal for PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) processes for creating magnetic and phosphor coatings.

- Semiconductor and Photovoltaics: Used in the production of semiconductors and solar cells due to their high-quality deposition properties.

- Metallurgical Additives: Acts as an additive in steel and alloy production to enhance mechanical and corrosion-resistant properties.

- Catalysis: Used as a catalyst in chemical reactions requiring phosphide-based materials.

- Research and Development: Widely employed in academic and industrial research for developing advanced materials.

Product Advantages

- High Purity: Guarantees reliable results in critical applications.

- Durability: Outstanding thermal and chemical stability for high-temperature processes.

- Custom Solutions: Pellet sizes and specifications can be tailored for specialized needs.

- Consistency: Uniform quality ensures predictable and repeatable performance.

Packaging and Storage

① Packaging

- Sealed in moisture-proof aluminum foil bags or airtight containers (e.g., 1kg, 5kg, 25kg).

- Customized packaging available upon request.

② Storage

- Store in a dry, cool environment to avoid oxidation and contamination.

- Ensure containers are sealed tightly to maintain product integrity.

Quality Certifications

- ISO 9001 Certified Quality Management System.

- RoHS Compliance.

- Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS) available upon request.

Frequently Asked Questions (FAQs)

- Q: Can the size of Fe₃P Pellets be customized?

A: Yes, we offer custom pellet sizes to meet your specific needs. - Q: What industries commonly use Fe₃P Pellets?

A: They are widely used in semiconductors, photovoltaics, metallurgical processes, and catalytic applications.

For additional details or to request a quote, contact us. Our team of experts is ready to assist you with tailored solutions for your project needs.