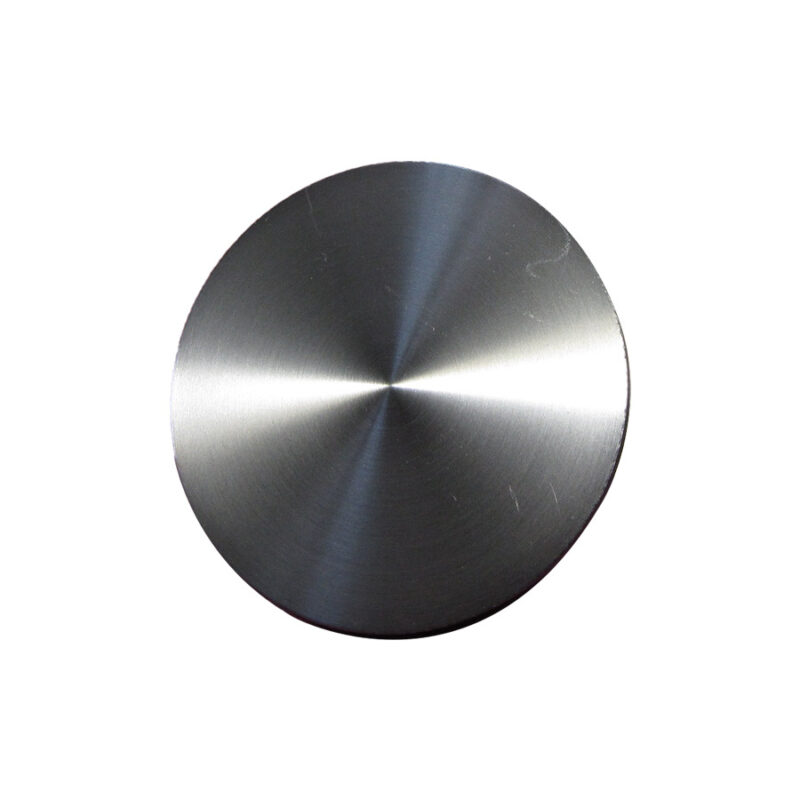

FeGa (Iron-Gallium) Sputtering Targets

- High Magnetostriction: FeGa alloys exhibit superior magnetostrictive properties, providing enhanced performance in functional films.

- Customizable Compositions: Available in various iron-gallium ratios to meet specific application requirements.

- High Purity: Ensures consistent and reliable thin-film deposition with minimal contamination.

- Excellent Magnetic Properties: Combines strength and magnetic responsiveness for advanced thin-film applications.

- Durable and Stable: Provides robust and long-lasting performance in challenging environments.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Iron Gallium (FeGa) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

FeGa sputtering targets, composed of an iron-gallium alloy, are renowned for their exceptional magnetostrictive properties, making them a preferred choice for thin-film applications in sensors, actuators, and transducers. This alloy, commonly referred to as Galfenol, combines the magnetic strength of iron with the enhanced magnetostrictive behavior introduced by gallium. FeGa sputtering targets are manufactured with high purity and precision to meet the stringent requirements of modern thin-film deposition processes.

Key Applications

- Magnetostrictive Sensors and Actuators: Ideal for creating films that respond to magnetic fields by changing dimensions.

- Microelectromechanical Systems (MEMS): Utilized in thin-film technologies for MEMS devices requiring magnetostrictive functionality.

- Energy Harvesting Devices: Applied in devices that convert mechanical energy into electrical energy using magnetostrictive materials.

- Magnetic Thin Films: Suitable for advanced research and development in magnetic and magnetostrictive thin-film materials.

Features and Benefits

- High Magnetostriction: FeGa alloys exhibit superior magnetostrictive properties, providing enhanced performance in functional films.

- Customizable Compositions: Available in various iron-gallium ratios to meet specific application requirements.

- High Purity: Ensures consistent and reliable thin-film deposition with minimal contamination.

- Excellent Magnetic Properties: Combines strength and magnetic responsiveness for advanced thin-film applications.

- Durable and Stable: Provides robust and long-lasting performance in challenging environments.

Specifications

- Purity: Typically 99.9% or higher to ensure minimal impurities.

- Composition: Customizable Fe-Ga ratios, such as Fe81Ga19 or other specified ratios.

- Dimensions: Custom sizes and shapes to fit diverse sputtering systems.

- Forms: Discs, plates, or custom geometries available.

- Density: Optimized for uniform sputtering and efficient thin-film deposition.

Customization Options

- Tailored Composition: FeGa targets can be fabricated with specific gallium content to meet application needs.

- Size and Shape: Targets are available in a variety of dimensions and geometries for compatibility with different deposition systems.

- Backing Plates: Optional backing materials for improved thermal conductivity and mechanical stability.

For detailed information on FeGa sputtering targets or to requst a custom quote, please contact us. Our team is ready to assist with your unique thin-film deposition requirements.