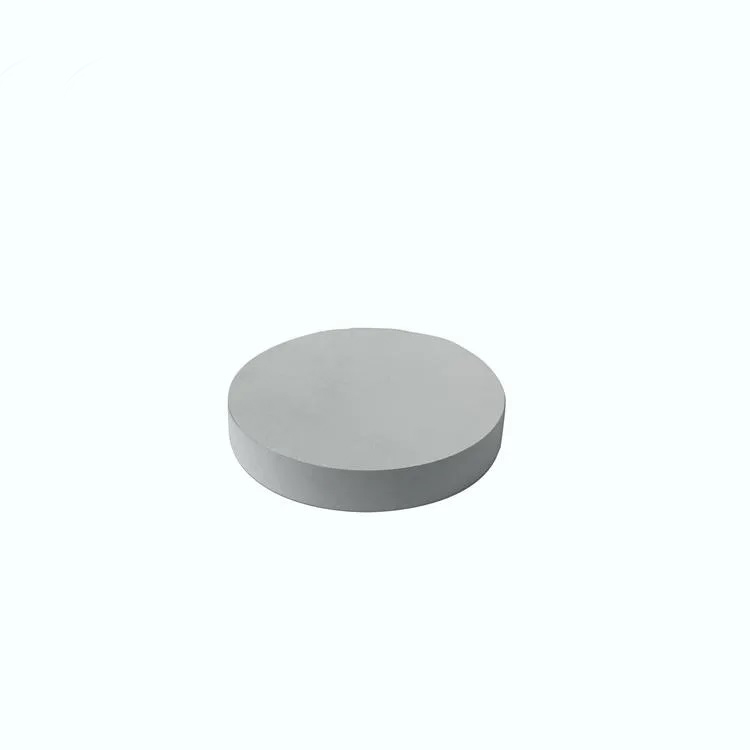

HfO2 (Hafnium Dioxide) Sputtering Target

- High Dielectric Constant: HfO₂ offers a high k-value, making it suitable for advanced gate dielectrics in semiconductor applications, allowing better transistor scaling.

- Optical Transparency: HfO₂ films are transparent over a wide range of wavelengths, from UV to IR, making them ideal for optical coatings in lenses and mirrors.

- Thermal and Chemical Stability: HfO₂ sputtering targets produce thin films with excellent resistance to high temperatures and harsh environments, ensuring durability in industrial and research applications.

- Ferroelectric Properties: HfO₂ can exhibit ferroelectric behavior, making it crucial for non-volatile memory devices such as FeRAM.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | HfO2 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Hafnium Dioxide (HfO₂), also known as hafnia, is a high-performance ceramic material widely used in thin-film deposition for advanced electronics, optics, and energy applications. HfO₂ sputtering targets are known for their high dielectric constant, excellent thermal stability, and strong resistance to corrosion, making them ideal for applications in semiconductors, optical coatings, and memory devices.

Key Applications:

- Semiconductors: HfO₂ thin films are used as a gate dielectric in MOSFET transistors due to their high dielectric constant (k-value), which enables improved scaling and performance in modern semiconductor devices. It replaces traditional silicon dioxide (SiO₂) as the insulating layer in advanced CMOS technologies.

- Optical Coatings: HfO₂ is a popular material for optical coatings due to its high refractive index and transparency in the ultraviolet (UV) to infrared (IR) range. It is often used in multilayer coatings for anti-reflective (AR) lenses, mirrors, and laser optics.

- Ferroelectric Memories: HfO₂ thin films exhibit ferroelectric properties, which are critical for next-generation memory devices like ferroelectric random access memory (FeRAM), offering faster speeds, lower power consumption, and better endurance.

- High-Temperature Sensors: Due to its high thermal stability, HfO₂ thin films are used in sensors and protective coatings that operate at elevated temperatures, such as those in aerospace and automotive industries.

- Energy Storage: The excellent dielectric properties of HfO₂ make it a valuable material in capacitors and energy storage devices, where it improves energy efficiency and performance.

Features of HfO₂ Sputtering Targets:

- High Dielectric Constant: HfO₂ offers a high k-value, making it suitable for advanced gate dielectrics in semiconductor applications, allowing better transistor scaling.

- Optical Transparency: HfO₂ films are transparent over a wide range of wavelengths, from UV to IR, making them ideal for optical coatings in lenses and mirrors.

- Thermal and Chemical Stability: HfO₂ sputtering targets produce thin films with excellent resistance to high temperatures and harsh environments, ensuring durability in industrial and research applications.

- Ferroelectric Properties: HfO₂ can exhibit ferroelectric behavior, making it crucial for non-volatile memory devices such as FeRAM.

Customization Options:

- Target Sizes: HfO₂ sputtering targets are available in various shapes and sizes, including circular, rectangular, and custom geometries, to fit different deposition systems.

- Purity Levels: High-purity HfO₂ targets (up to 99.99%) ensure superior film quality for critical applications in semiconductors, optics, and memory devices.

- Bonding Services: HfO₂ targets can be bonded to backing plates to improve thermal management during sputtering, ensuring consistent film deposition and reducing the risk of target cracking.

HfO₂ (Hafnium Dioxide) sputtering targets from Tinsan Materials are ideal for thin-film deposition in semiconductors, optics, and energy storage. With high dielectric constant, optical transparency, and thermal stability, HfO₂ targets offer customizable sizes and high-purity options for precise thin-film applications, including MOSFETs, AR coatings, and memory devices.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.