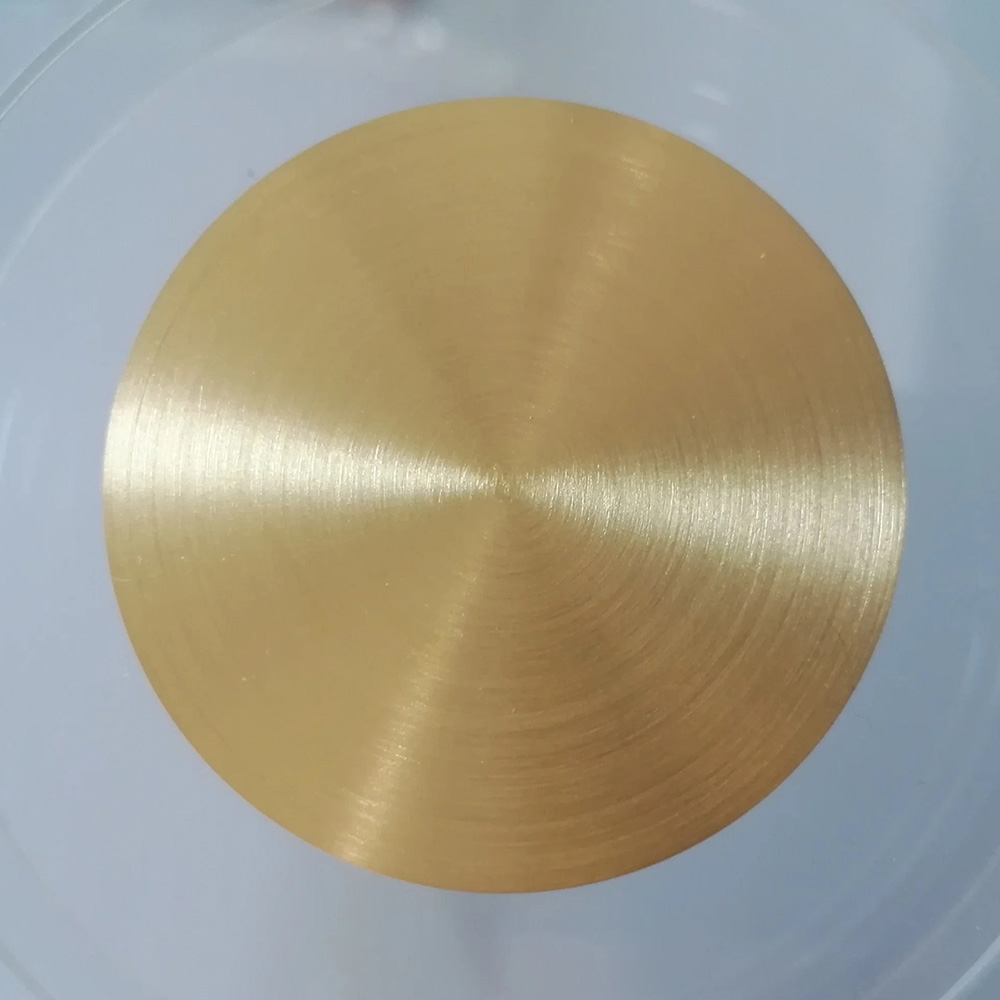

Au Gold Sputtering Target

Gold (Au) sputtering target is a very important material of semiconductor, it’s used for depositing gold thin film on the surface of semiconductor chips, to form ohmic contact film, electrode or other films, it can form various metallic films system. Most of gold oxide film system can be used for manufacturing LED, microwave communication device, widely applied in spaceflight, aviation, semiconductor chips and Solar Cells.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Gold (Au) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag |

| Place of Origin | China |

| MOQ | 1pc |

| Supply Ability | 10000pcs per month |

| Lead time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Gold (Au) sputtering targets are used in physical vapor deposition (PVD) processes to create thin films and coatings on substrates for various applications. These targets are composed of high-purity gold and are often utilized in industries such as electronics, optics, and jewelry due to gold’s excellent conductivity, corrosion resistance, and reflectivity.

Key Features:

- Purity: Typically, gold sputtering targets are available with a purity of 99.99% (4N) or higher to ensure high-quality coatings.

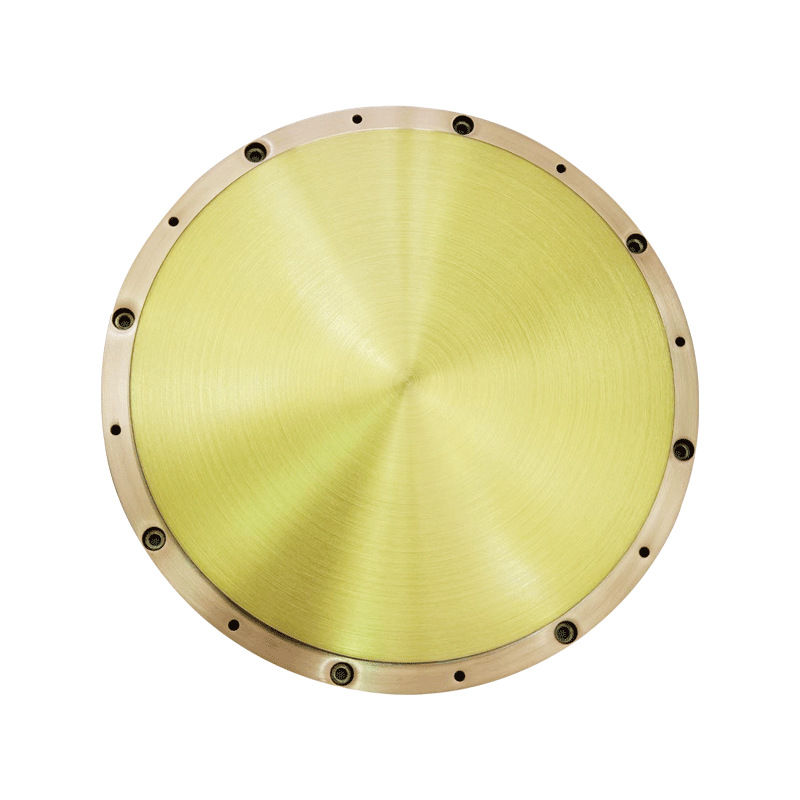

- Shapes and Sizes: These targets can be manufactured in various shapes, such as discs, plates, or cylinders, and can be custom-sized to fit different sputtering systems.

Applications:

- Electronics: Gold coatings are used in semiconductor devices, connectors, and printed circuit boards (PCBs) for their excellent electrical conductivity and resistance to oxidation.

- Optics: Gold coatings are applied to optical components, such as mirrors and lenses, to enhance reflectivity in the infrared (IR) region.

- Jewelry and Decorative Coatings: Gold sputtering is used for creating thin decorative coatings on various materials, providing a luxurious finish with the added benefit of durability.

Customization Options:

- Thickness: The thickness of the gold coating can be precisely controlled during the sputtering process, allowing for customization according to specific application requirements.

- Backing Plates: Gold sputtering targets can be bonded to backing plates made of materials like copper or molybdenum to enhance thermal conductivity and structural integrity during the sputtering process.

Considerations:

- Cost: Due to the high cost of gold, sputtering targets are more expensive than other materials. However, the benefits of gold coatings often outweigh the cost, especially in high-performance or luxury applications.

- Target Utilization: Efficient utilization of the target material is essential to minimize waste and reduce costs in the sputtering process.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.