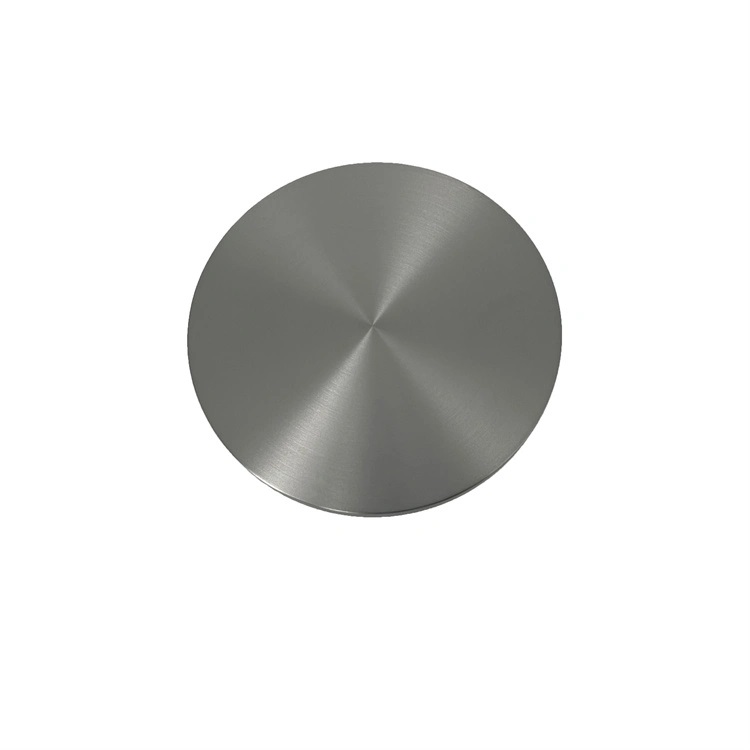

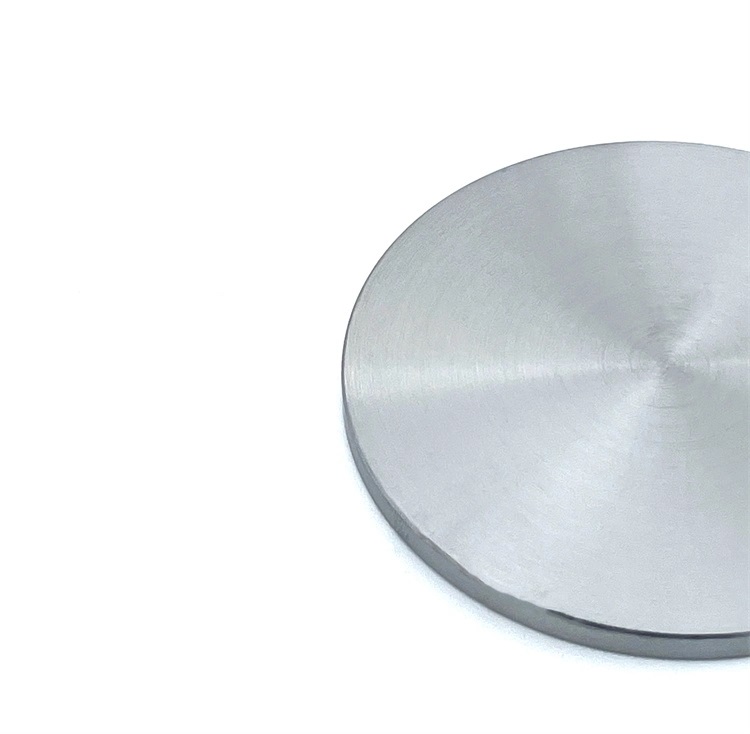

Ir Iridium Sputtering Target

- High Purity: Iridium sputtering targets are available in ultra-high purity (up to 99.99%) to ensure the deposition of superior thin films for sensitive electronics and optical components.

- Thermal Stability: Iridium’s high melting point (~2446°C) makes it ideal for thin films that must withstand extreme heat in aerospace, semiconductor, and other high-temperature environments.

- Corrosion Resistance: Iridium is one of the most corrosion-resistant metals, ensuring long-lasting films in harsh chemical environments.

- Electrical Conductivity: Iridium thin films offer excellent electrical conductivity, making them essential for electronic applications requiring efficient current flow.

- Customizable Size and Shape: Available in various forms, including discs, plates, and custom geometries, to fit different PVD systems.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Iridium (Ir) |

| Purity | 99.9% – 99.999% / 3N 3N5 4N 4N5 5N |

| Shape | disc, plate, sheet, rod, customized |

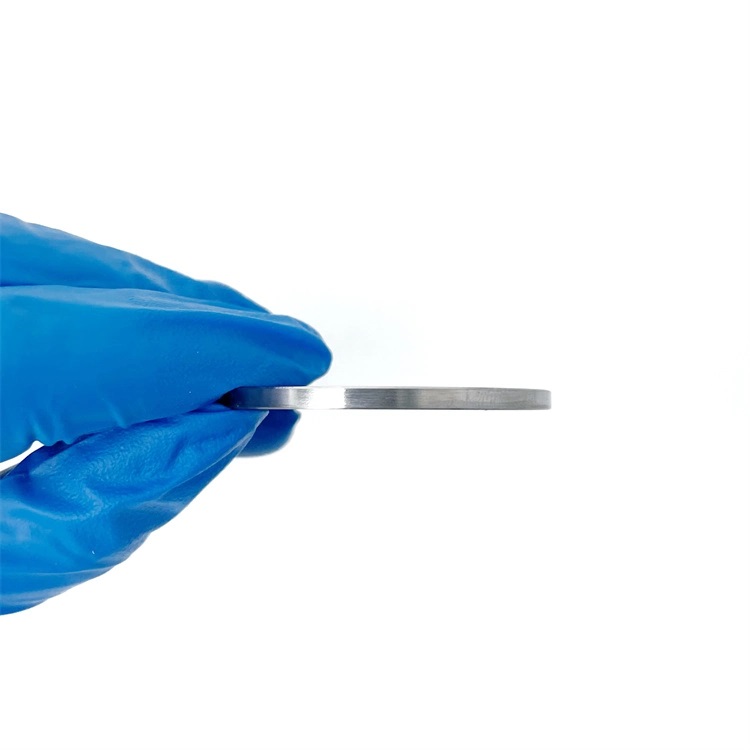

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Iridium (Ir) sputtering targets are highly sought after for physical vapor deposition (PVD) processes due to iridium’s exceptional chemical, thermal, and electrical properties. Iridium (Ir) is a rare and extremely dense metal with high melting points and corrosion resistance, making it ideal for various high-performance applications.

Key Applications:

- Semiconductor Industry: Iridium thin films are used in semiconductor devices, including memory chips, logic circuits, and integrated circuits, where high thermal stability and electrical conductivity are critical.

- Electronics: Iridium films are utilized in advanced electronic components, such as OLED displays, microelectromechanical systems (MEMS), and conductive coatings.

- Aerospace: Iridium coatings provide durability and oxidation resistance in extreme aerospace environments, including high-temperature components such as jet engine parts.

- Catalysis: Iridium’s catalytic properties make it useful in chemical reactions for fuel cells and other energy applications.

- Medical Devices: Due to its biocompatibility and corrosion resistance, iridium thin films are used in medical devices, especially in implantable electronics.

- Optics: Iridium is used in optical coatings, such as reflectors and mirrors for telescopes, cameras, and other precision instruments, offering high reflectivity across a wide range of wavelengths.

Features of Iridium Sputtering Targets:

- High Purity: Iridium sputtering targets are available in ultra-high purity (up to 99.99%) to ensure the deposition of superior thin films for sensitive electronics and optical components.

- Thermal Stability: Iridium’s high melting point (~2446°C) makes it ideal for thin films that must withstand extreme heat in aerospace, semiconductor, and other high-temperature environments.

- Corrosion Resistance: Iridium is one of the most corrosion-resistant metals, ensuring long-lasting films in harsh chemical environments.

- Electrical Conductivity: Iridium thin films offer excellent electrical conductivity, making them essential for electronic applications requiring efficient current flow.

- Customizable Size and Shape: Available in various forms, including discs, plates, and custom geometries, to fit different PVD systems.

Customization Options:

- Dimensions: Iridium sputtering targets can be customized in terms of diameter, thickness, and shape to meet specific deposition requirements.

- Purity Levels: Ultra-high purity iridium targets (up to 99.99%) are available for demanding applications in electronics, catalysis, and optics.

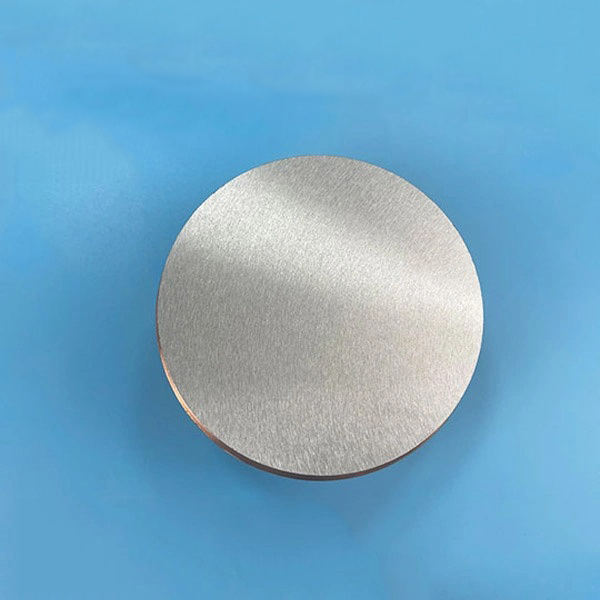

- Backing Plates: Optional backing plates are available for increased durability and handling during sputtering.

Iridium sputtering targets from Tinsan Materials offer high-purity Ir for thin film deposition in semiconductors, electronics, aerospace, catalysis, and optics. Custom sizes and shapes available for optimized PVD performance.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.