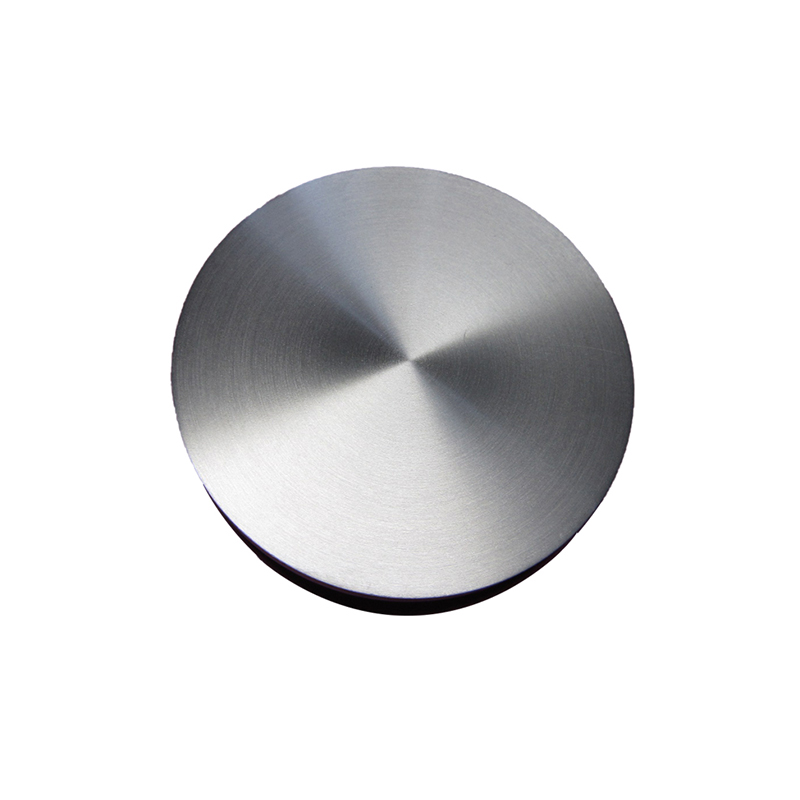

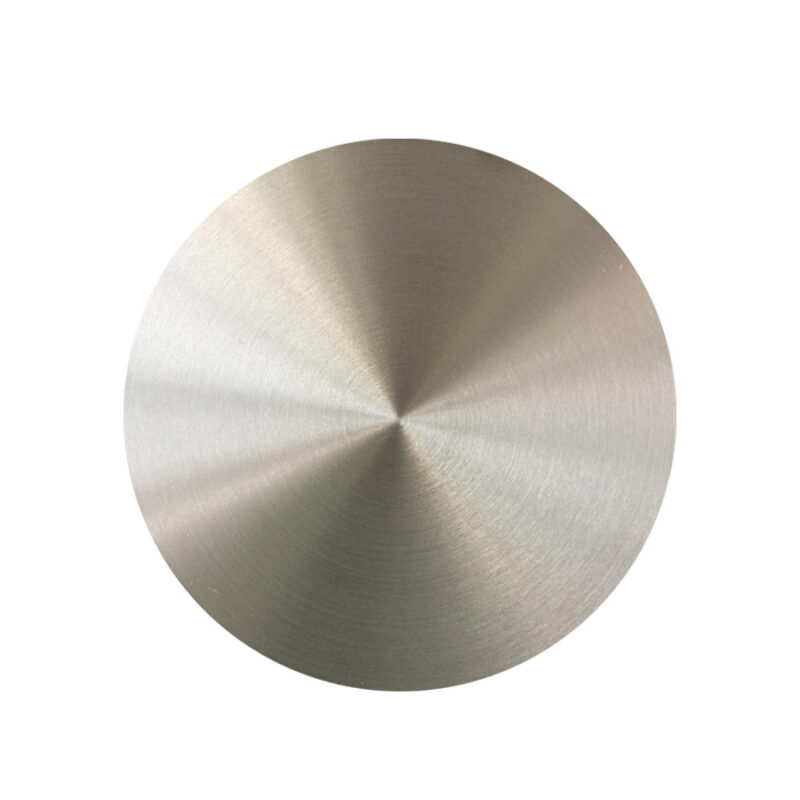

IrMn (Iridium Manganese) Alloy Target

- Antiferromagnetic Properties: IrMn alloy thin films exhibit strong antiferromagnetic behavior, which is essential for magnetic pinning in spintronic devices and memory storage.

- High Corrosion Resistance: Iridium provides excellent corrosion resistance, ensuring the durability and longevity of the deposited thin films, even in harsh environments.

- Thermal Stability: IrMn alloy films are thermally stable, making them ideal for high-temperature applications in electronic and magnetic devices.

- Customizable Size and Shape: IrMn sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit a wide range of deposition systems.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Iridium Manganese |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Iridium-Manganese (IrMn) alloy sputtering targets are used in physical vapor deposition (PVD) processes to deposit thin films for advanced magnetic and electronic applications. IrMn is an antiferromagnetic alloy, widely applied in spintronic devices and magnetic memory storage, where precise control of magnetic properties is required.

Key Applications:

- Magnetic Storage Devices: IrMn alloy thin films are used in magnetic storage technologies, particularly in spin-valve and tunneling magnetoresistance (TMR) devices, where they function as antiferromagnetic pinning layers.

- Spintronics: The IrMn alloy is crucial in spintronic devices, which utilize both the charge and spin of electrons to achieve improved data processing and storage capabilities.

- Magnetic Sensors: IrMn thin films are employed in magnetic sensors, including magnetic field detectors and read heads in hard drives, providing precise control of magnetic fields.

- Magnetic Random Access Memory (MRAM): The alloy is integral in MRAM devices, where it serves as a pinning layer to stabilize the reference magnetization direction in memory cells.

- Giant Magnetoresistance (GMR): IrMn films enhance the performance of GMR sensors and devices used in various fields such as automotive, industrial, and medical sensing.

Features of IrMn Alloy Sputtering Targets:

- Antiferromagnetic Properties: IrMn alloy thin films exhibit strong antiferromagnetic behavior, which is essential for magnetic pinning in spintronic devices and memory storage.

- High Corrosion Resistance: Iridium provides excellent corrosion resistance, ensuring the durability and longevity of the deposited thin films, even in harsh environments.

- Thermal Stability: IrMn alloy films are thermally stable, making them ideal for high-temperature applications in electronic and magnetic devices.

- Customizable Size and Shape: IrMn sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit a wide range of deposition systems.

Customization Options:

- Dimensions: IrMn alloy sputtering targets can be customized in diameter, thickness, and shape to meet specific PVD system requirements.

- Purity Levels: High-purity IrMn alloy sputtering targets are available to ensure optimal performance in advanced magnetic applications.

- Backing Plates: Optional backing plates can be provided to improve durability and ease of use during sputtering.

IrMn alloy sputtering targets from Tinsan Materials offer high-performance antiferromagnetic thin films for spintronics, magnetic storage, MRAM, and GMR applications. Custom sizes and shapes available for optimized PVD performance.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.