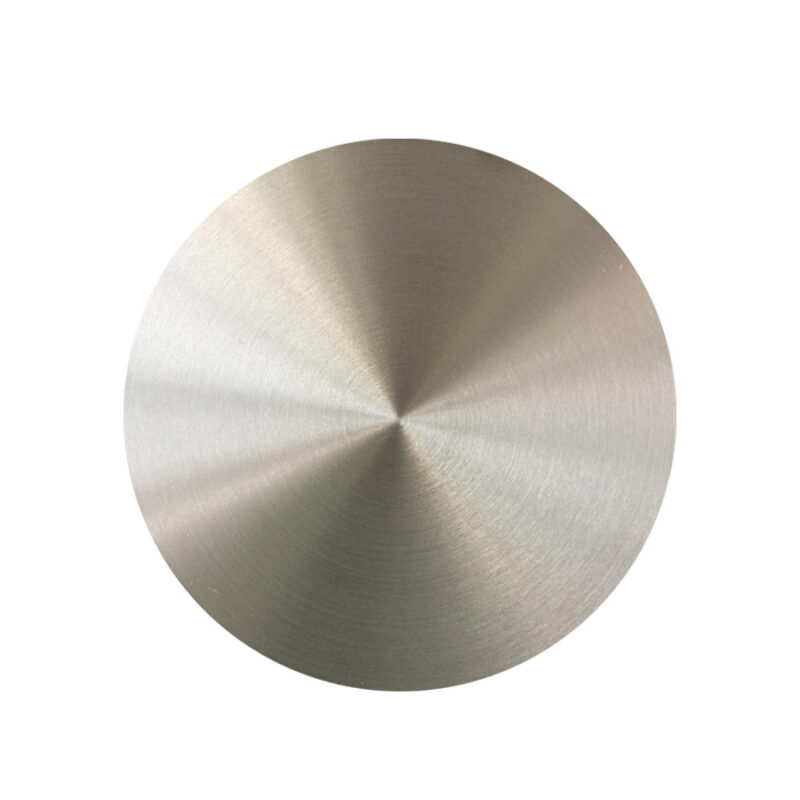

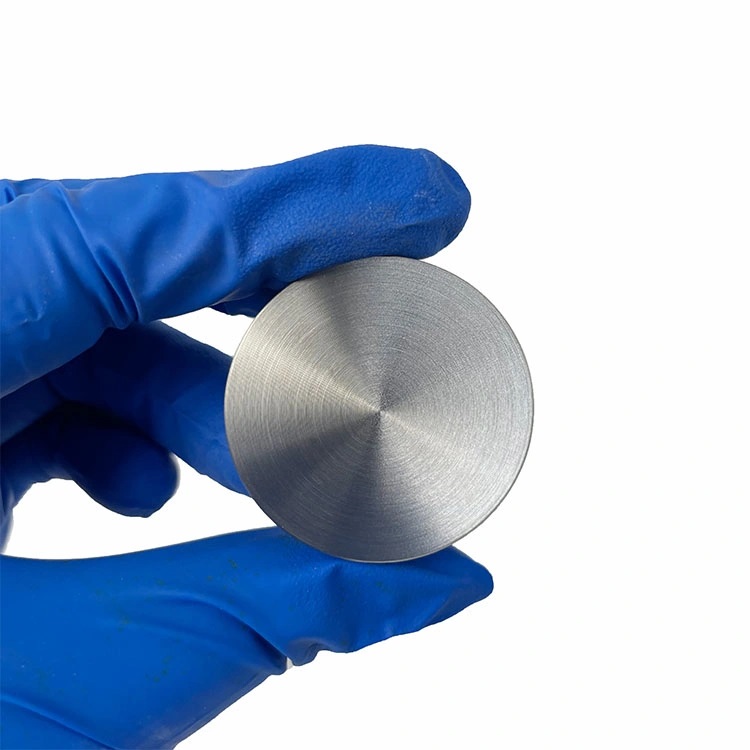

LiCoO2 (Lithium Cobalt Oxide) Sputtering Target

- High Energy Density: LiCoO₂ has a high theoretical energy density, making it an ideal material for battery cathodes, especially in high-performance applications like electric vehicles and portable electronics.

- Stable Structure: The layered crystal structure of LiCoO₂ contributes to its stable electrochemical performance, which is crucial for the long-term operation of lithium-ion batteries.

- Excellent Cycling Performance: LiCoO₂ can undergo many charge and discharge cycles without significant degradation, ensuring reliable performance in rechargeable battery systems.

- Thin Film Deposition: LiCoO₂ sputtering targets allow for the precise deposition of thin films in applications requiring uniform coatings, such as in thin-film batteries and microelectronics.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

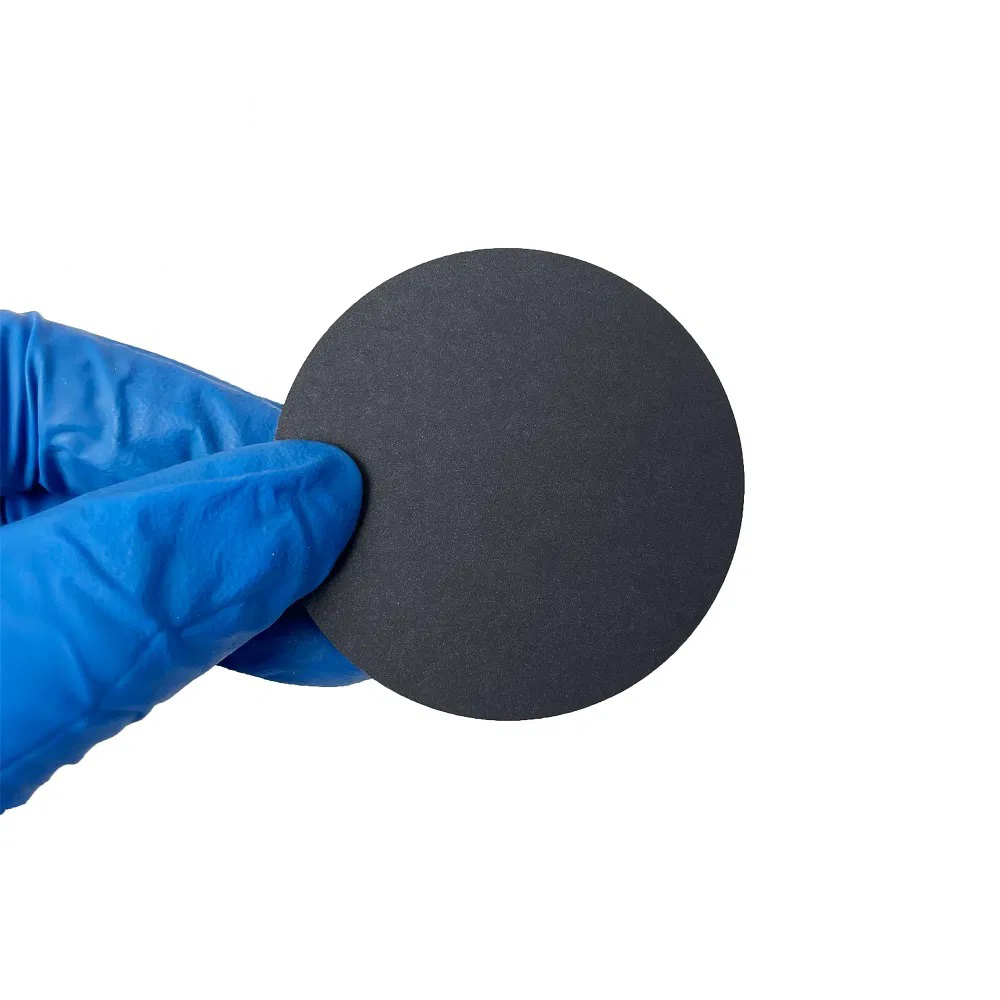

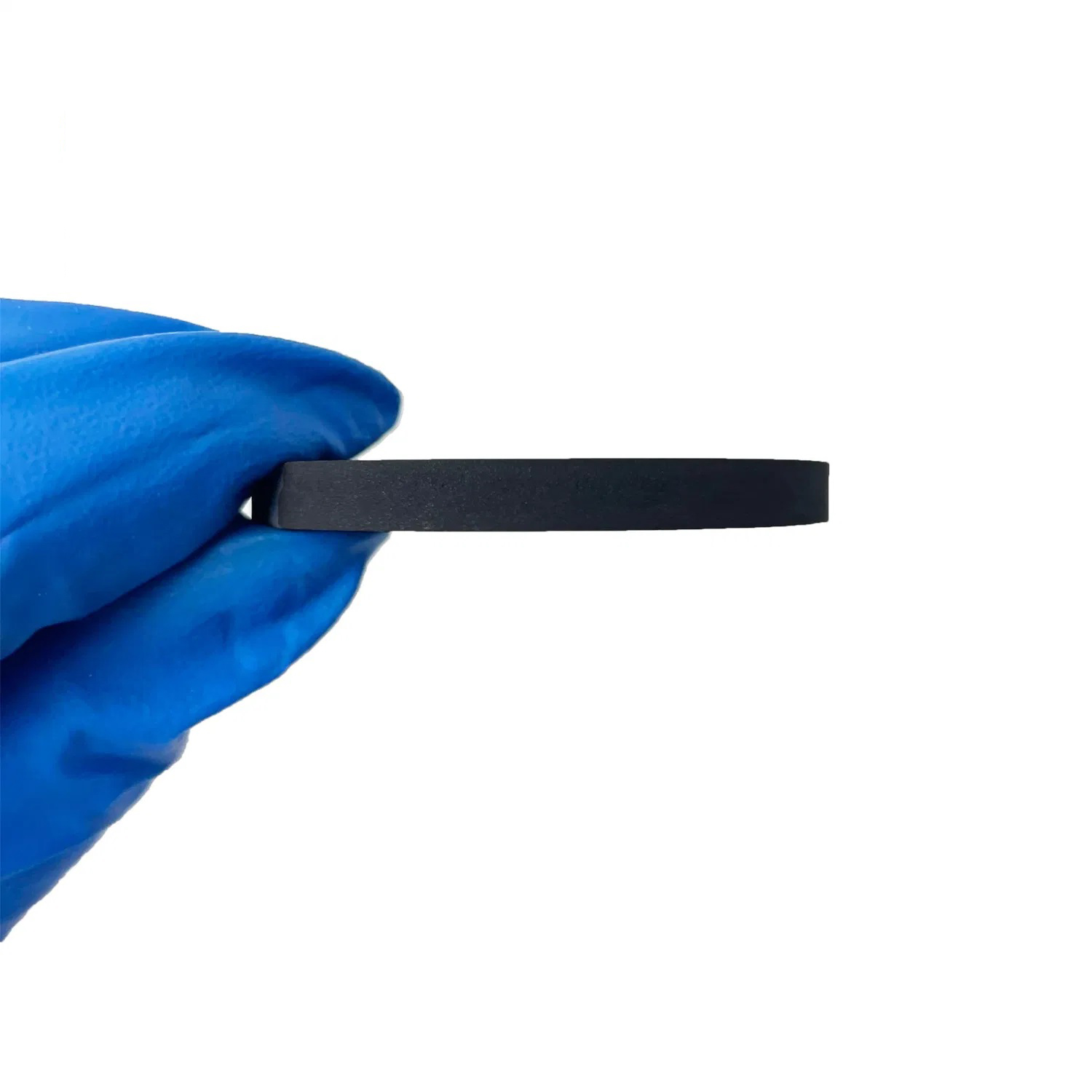

| Material | LiCoO2 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Lithium cobalt oxide (LiCoO₂) sputtering targets are widely used in thin-film deposition processes for applications in energy storage, especially in lithium-ion batteries. LiCoO₂ exhibits excellent electrochemical properties and is a popular cathode material for rechargeable batteries. It is also used in electronics, energy conversion, and coating applications.

Key Applications:

- Lithium-ion Batteries: LiCoO₂ is one of the most commonly used cathode materials in lithium-ion batteries due to its high energy density, stable structure, and reliable cycling performance. Thin films of LiCoO₂ are applied in battery cathodes to improve energy storage capacity and efficiency in portable electronics, electric vehicles, and renewable energy systems.

- Energy Storage: Beyond lithium-ion batteries, LiCoO₂ is used in other energy storage devices where high energy density and long-term cycling stability are required. It is particularly valued for applications that demand consistent performance over many charge and discharge cycles.

- Thin-film Solid-State Batteries: LiCoO₂ is also used in thin-film solid-state batteries, which offer improved safety and energy density compared to traditional liquid electrolyte batteries. The use of LiCoO₂ as a thin-film cathode material enhances the performance of these batteries in compact electronic devices.

- Electronics and Semiconductor Devices: LiCoO₂ thin films are utilized in microelectronics and semiconductor devices due to their electrochemical stability and conductive properties. They are used as coatings in sensors, capacitors, and other electronic components.

- Energy Conversion Devices: LiCoO₂ can also be used in devices such as fuel cells and hybrid systems for energy conversion, where its electrochemical properties contribute to efficient energy management.

Features of LiCoO₂ Sputtering Targets:

- High Energy Density: LiCoO₂ has a high theoretical energy density, making it an ideal material for battery cathodes, especially in high-performance applications like electric vehicles and portable electronics.

- Stable Structure: The layered crystal structure of LiCoO₂ contributes to its stable electrochemical performance, which is crucial for the long-term operation of lithium-ion batteries.

- Excellent Cycling Performance: LiCoO₂ can undergo many charge and discharge cycles without significant degradation, ensuring reliable performance in rechargeable battery systems.

- Thin Film Deposition: LiCoO₂ sputtering targets allow for the precise deposition of thin films in applications requiring uniform coatings, such as in thin-film batteries and microelectronics.

Customization Options:

- Target Sizes: LiCoO₂ sputtering targets are available in a variety of shapes and sizes, including planar and rotary designs, to suit different deposition systems.

- Purity Levels: High-purity LiCoO₂ targets (up to 99.99%) are provided to ensure high-quality deposition and optimal performance in advanced applications.

- Doping and Alloying: Custom doping options are available to modify the properties of LiCoO₂ thin films, enhancing performance for specific applications such as improved cycling stability or conductivity.

LiCoO₂ (Lithium Cobalt Oxide) sputtering targets from Tinsan Materials are ideal for lithium-ion batteries, thin-film energy storage, and semiconductor applications. High-purity, customizable LiCoO₂ targets for advanced thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.